Anti-buckling low yield point steel-composite energy dissipation brace

A low-yield point steel and composite material technology, applied in the field of energy-consuming supports, can solve the problems of buckling under compression and poor hysteretic performance of ordinary supports, and achieve the effects of strong designability, improved bearing capacity, and convenient forming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

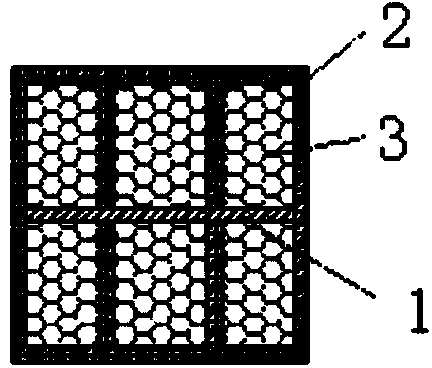

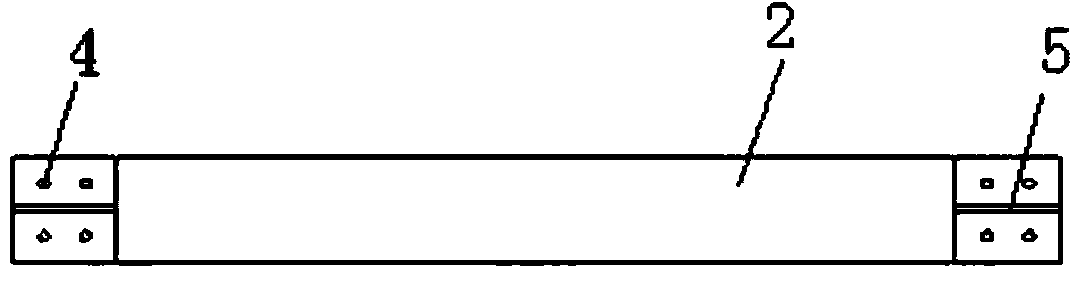

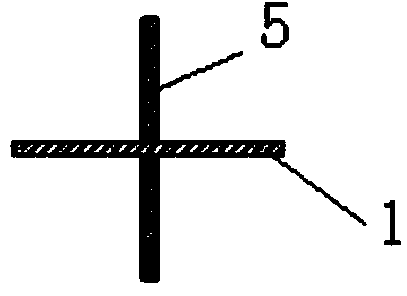

[0044] Embodiment 1, as figure 1 , 2As shown, the present invention is a buckling-free low-yield point steel-composite material energy-dissipating support, which is composed of peripheral composite material constraining units that are integrally sealed and wrapped around an inner core force-bearing unit, and the inner core force-bearing unit is a low-yield point steel core The steel core 1 and the outer composite material constraining unit are composed of ribbed GFRP tube 2 and polyurethane foam 3 inside the tube, and the GFRP ribs in the tube are evenly distributed, and the core steel core 1 is a straight 08F steel core steel core. The ribbed GFRP pipe 2 is a square pipe. The inner core steel core 1 and the peripheral composite material constraining unit are integrally formed by vacuum introduction at one time, and the connection parts at both ends of the inner core steel core 1 are provided with a plurality of screw holes 4, such as image 3 As shown, GFRP stiffeners 5 pe...

Embodiment 2

[0045] Embodiment 2, a buckling-free low yield point steel-composite material energy-dissipating support, same as Embodiment 1, the GFRP pipe 2 is set in a circle, and the 08F steel inner core steel core is in the shape of a cross.

[0046] The present invention is a buckling-free low-yield point steel-composite material energy-dissipating support. When working, the inner core stress unit and the peripheral restraint unit are stressed as a whole, that is, the axial tensile pressure borne by the support is determined by the inner core stress unit Shared with the surrounding constrained elements. The inner core force unit can reach yield when it is under tension. Because the elastic modulus E of GFRP c Less than the elastic modulus E of steel s Therefore, under the condition of consistent deformation, composite materials can consume more energy. When the support is under compression, the steel stress first reaches the yield strength f ys , resulting in a yield strain ε ys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com