Shield end socket reinforcing system of scree soil layer advance large pipe roof and construction method thereof

A technology of advanced large pipe shed and pipe shed, which is applied in earthwork drilling, underground chamber, wellbore lining, etc., can solve the problems of underutilized pebble soil layer upright stability, difficult to guarantee reinforcement effect, and difficult implementation, etc. Achieving the effect of wide application value, solving construction difficulties and reducing engineering risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in combination with specific embodiments.

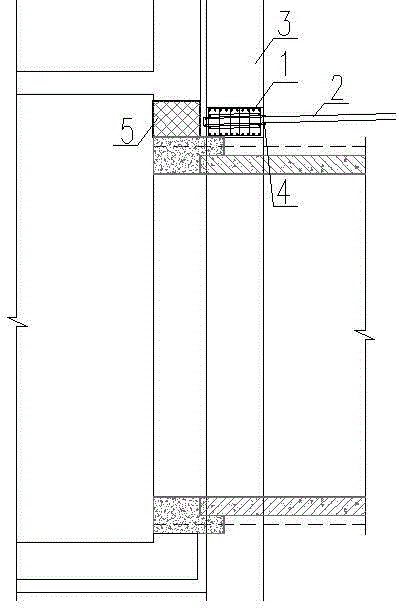

[0030] The present invention is based on the premise that glass fiber bars are used to enclose protection piles in the range of shield tunnels. After the station or shield well structure is basically completed, tie beams are installed between the piles as pipe shed guide walls to control the shield section. In the arch area of the tunnel section, advance pre-grouting of the large pipe shed is implemented to strengthen the stratum; at the same time, combined with construction precipitation, the stratum stability of the shield entering and exiting the tunnel is ensured.

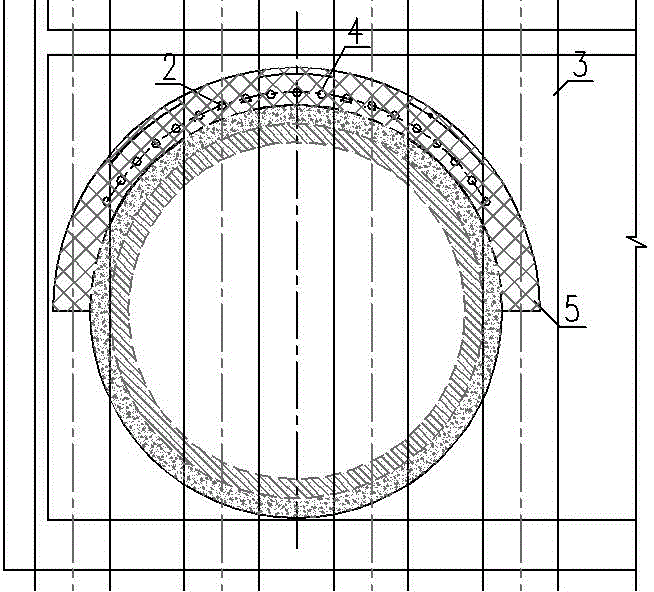

[0031] The shield end reinforcement system of the advanced large tube shed in the cobblestone soil layer of the present invention includes shield well glass fiber reinforcement enclosing protection piles 3 built around the opening range of the shield well end, and shield well glass fiber reinforcement A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com