Gob-side entry retaining method for GFRP (Glass Fiber Reinforced Polymer) tube concrete pier stud and gangue concrete wall

A technology of concrete piers and concrete walls, which is applied in the direction of earthwork drilling, filling, safety devices, etc., can solve the problems of failure to achieve expected results, bending and deformation of single hydraulic props, and decline in the bearing capacity of roadside filling walls. Achieve the effect of simple structure and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0020] The method for the GFRP tube concrete pier column and the gangue concrete wall to retain the gob-side entry of the present invention, its preferred specific implementation mode is:

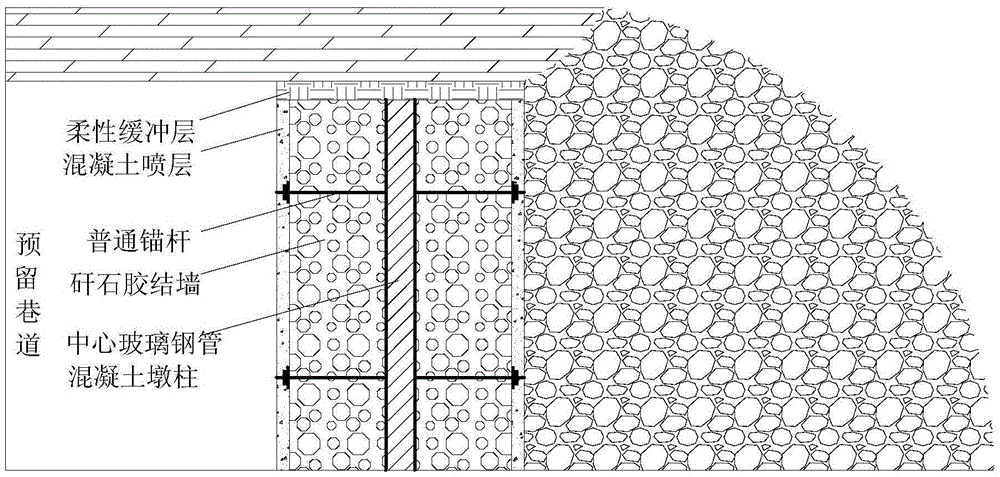

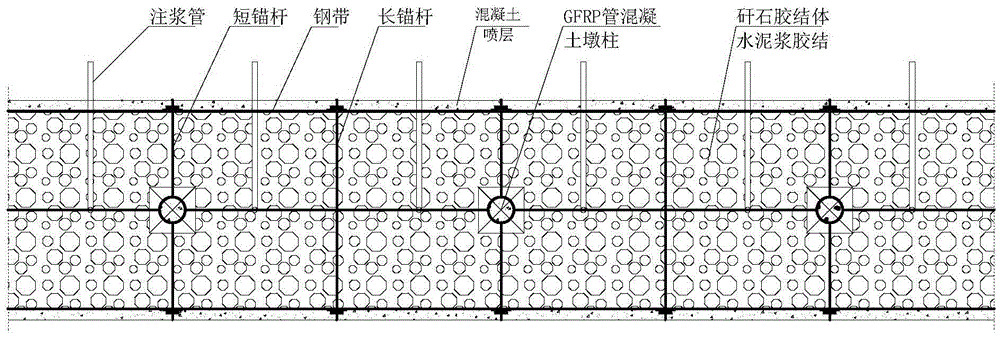

[0021] In the center of the side support body of the gob-side entry retaining, install FRP concrete piers at intervals of 2 to 3m, construct a support space by the side of the road with the pier of glass steel pipes as the center, and fill the gangue in the support space by the side of the roadway For the wall, both sides of the gangue wall are sealed with sprayed concrete, and fast-hardening cement slurry is injected into the gangue wall to make it cemented, and finally a lane with GFRP pipe concrete piers as the central skeleton and gangue cemented walls as auxiliary protection is formed. side support body.

[0022] When retaining the roadway, the fiberglass steel pipe concrete is used as the center, and the roadside support body space is constructed with steel strips, anchor rods and ste...

specific Embodiment

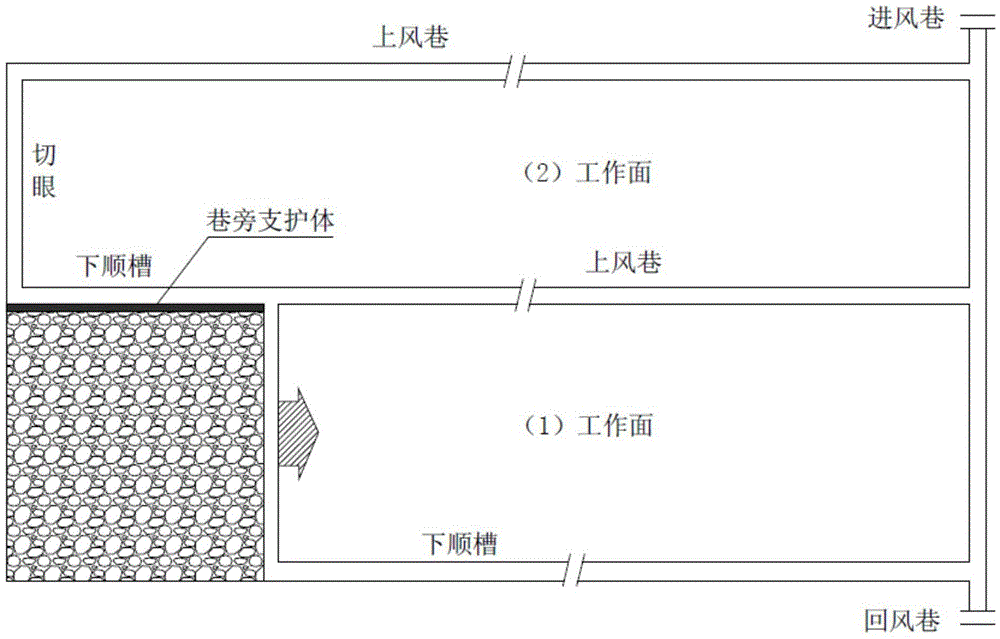

[0032] Taking the Φ400mm×14mm glass steel pipe filled with C60 concrete as an example, a roadside support body with a width of 2m and a height of 3m is simulated to be constructed, and the roadside support is supported by anchor mesh cables. The layout of the simulated working surface is as follows: figure 1 , the section of gob-side entry retaining is as follows figure 2 , the roadside support body such as Figure 3a , Figure 3b , the cross-section of the roadside support body is as follows Figure 4a , Figure 4b , Figure 4c .

[0033] Construction steps of support beside gob-side entry retaining:

[0034] The flow chart of the construction steps of the roadside support along the gob-side entry retention is as follows: Figure 5 shown.

[0035] As the coal mining face advances, a hydraulic support on the lagging face begins to work along the gob-side entry.

[0036] First, erect empty glass steel pipe piers along the edge of the working face, and add wooden board...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com