Large-area deep soft foundation preloading comprehensive treatment method combined with production and operation management

A preloading preloading technology for weak foundations, applied in infrastructure engineering, soil protection, construction, etc., can solve problems such as large investment in engineering construction, long construction period, and difficult to deal with

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

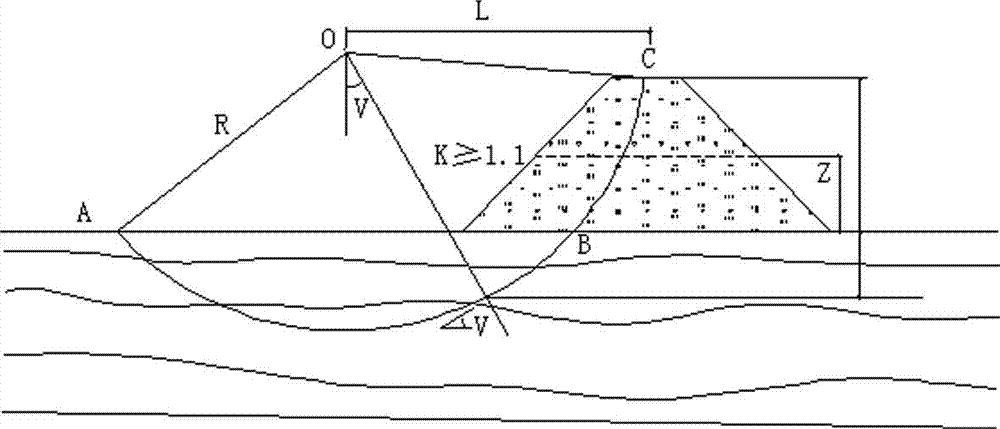

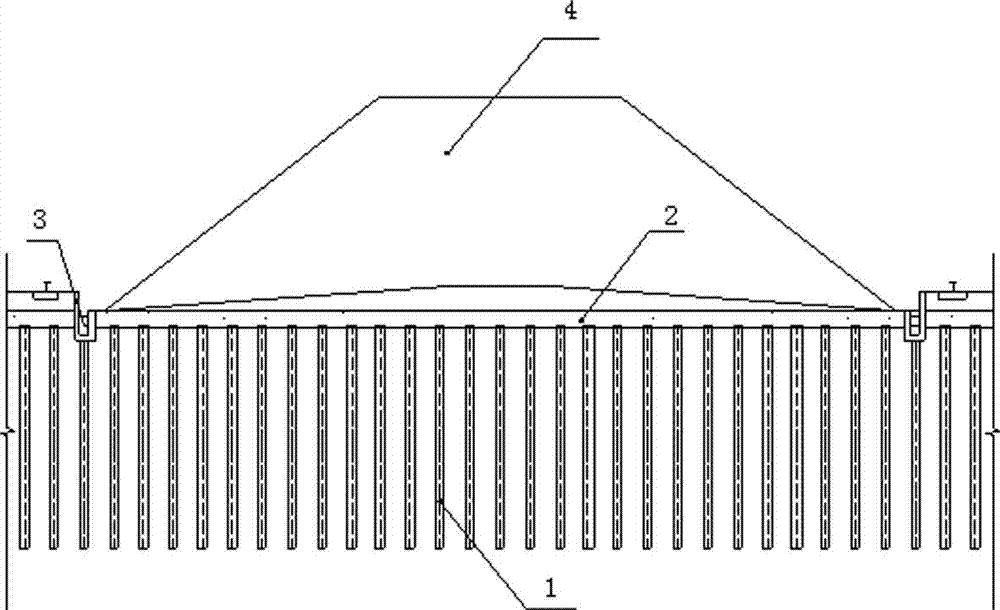

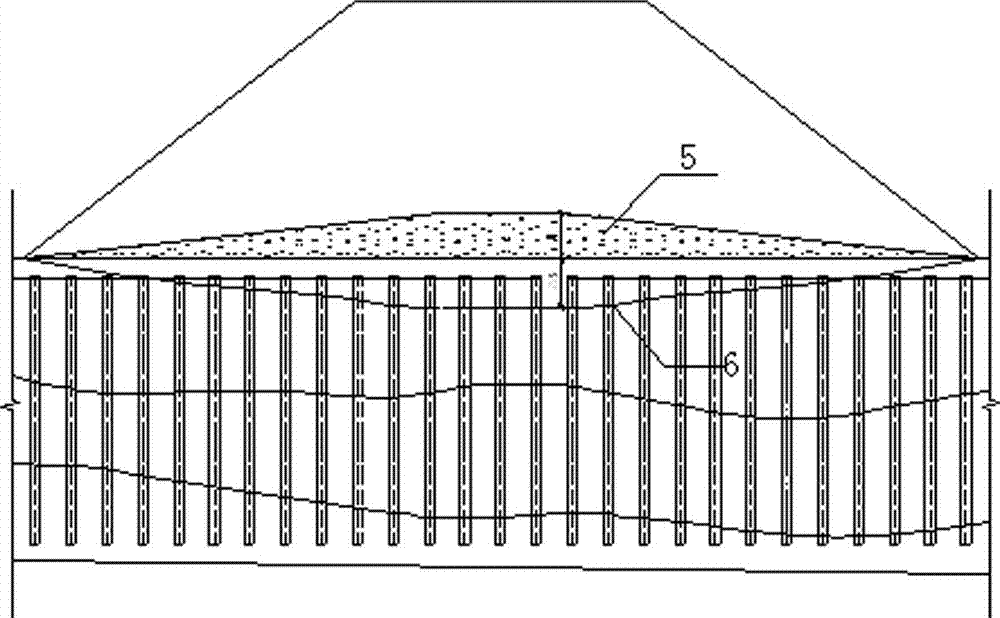

[0050] according to Figure 1~Figure 6 As shown, a large-area, deep, weak foundation surcharge preloading comprehensive treatment method combined with production and operation management, its specific implementation method is as follows:

[0051] 1. Foundation treatment design and calculation: According to the parameters of the foundation rock and soil layer of the site to be treated, cooperate with the vertical and horizontal drainage systems, and in accordance with the principle that the foundation stability coefficient is greater than 1.1, estimate the maximum height of the first-level stockpiling of the foundation and the first-level Consolidation time of foundations under stockpile loads.

[0052]2. According to the designed drainage system plan, the drainage system is constructed in the soft soil foundation, mainly including the vertical drainage system and the horizontal drainage system. Generally, sand and gravel piles (wells) are pre-drilled before loading, or plastic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com