Optimization design method for hydraulic fracture parameters of repeated fracturing of shale gas horizontal wells

A technology of repeated fracturing and hydraulic fracturing, which is applied in calculation, earthwork drilling, wellbore/well components, etc. It can solve problems such as difficulty in obtaining industrial gas flow, inability to effectively exploit shale gas, and poor distribution of proppant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0136] Example: The known geological parameters and primary fracturing construction parameters of a typical shale gas reservoir are shown in Table 1:

[0137] Table 1 Geological parameters and construction parameters of shale gas field

[0138]

[0139]

[0140] The present invention relates to a method for optimal design of hydraulic fracture parameters for repeated fracturing of shale gas horizontal wells. The specific steps are as follows:

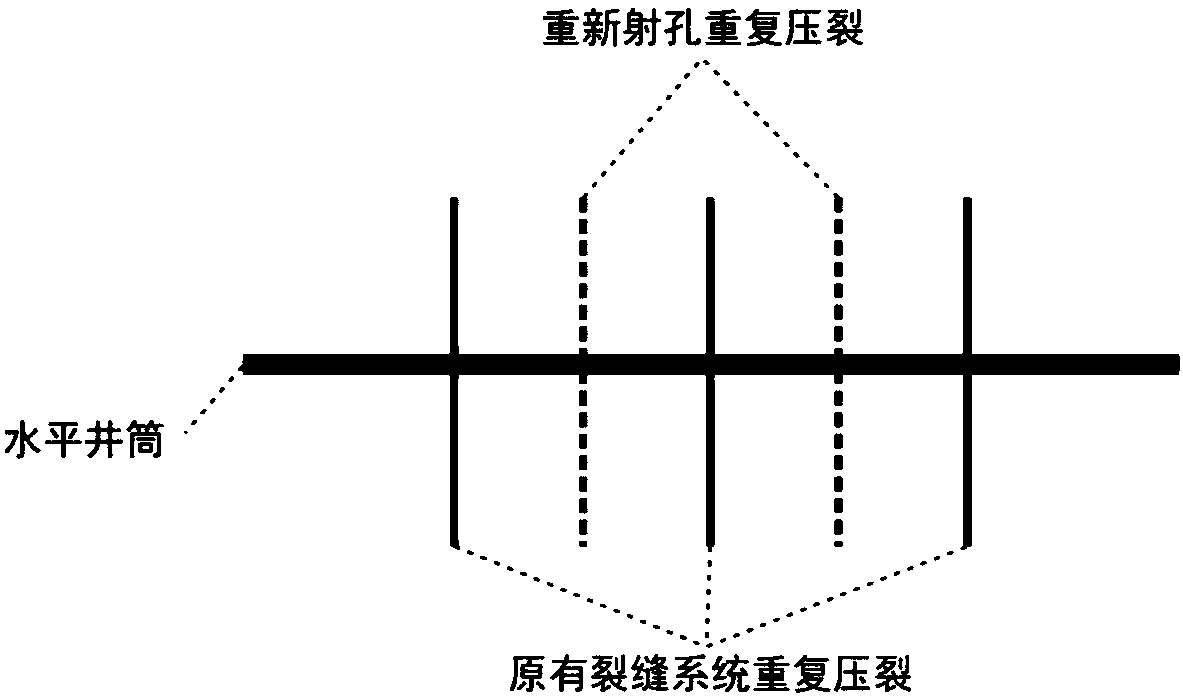

[0141] (a) Establish a numerical model for productivity prediction of shale gas well refracturing considering the complex fracture morphology and multi-scale flow behavior of shale reservoir after primary fracturing. For the stress balance equation, shale gas flow equation in kerogen, shale gas flow equation in inorganic matter and shale gas flow equation in fracture system included in the model, see equations (1) to (4) respectively.

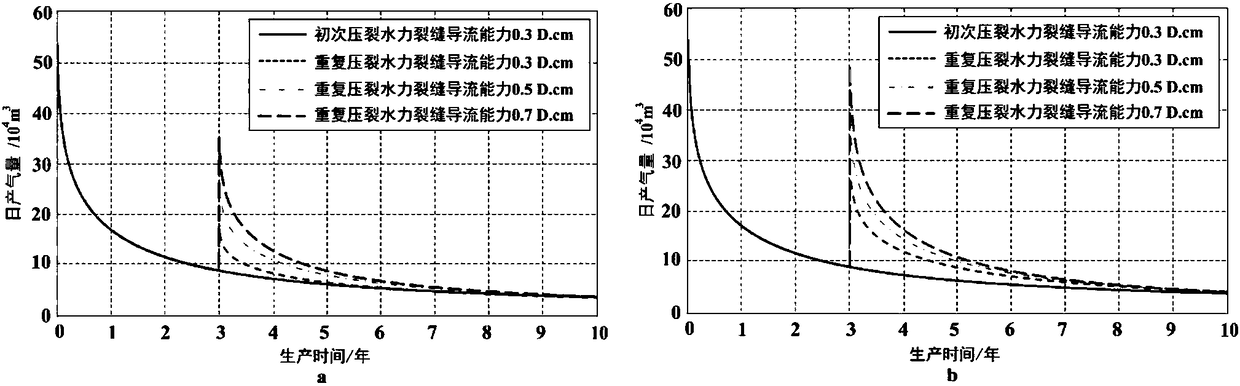

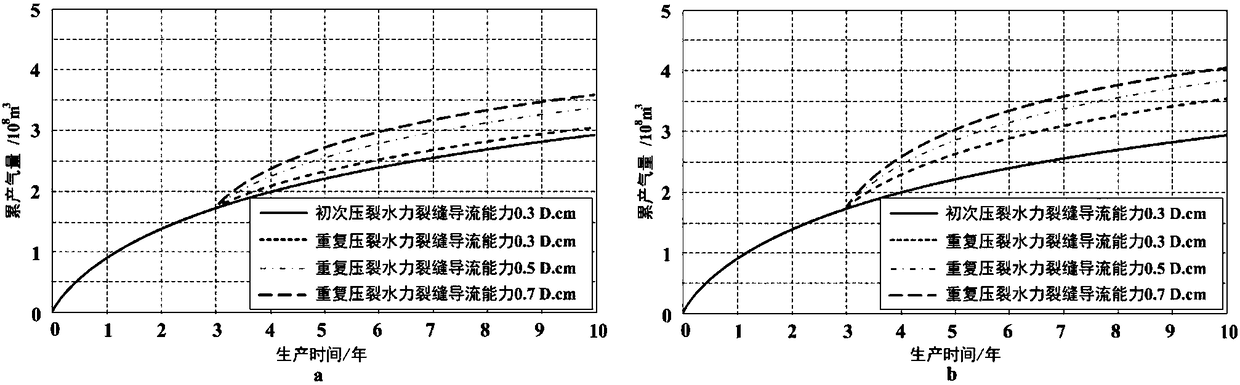

[0142] (b) Solve the productivity prediction numerical model established in step (a) numerical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com