Shale fracture flow simulation apparatus

a flow simulation and fracture technology, applied in the direction of design optimisation/simulation, survey, borehole/well accessories, etc., can solve the problems of shale oil and gas tightly held, difficult to release, and vertical fracture to open, and slow the industry's learning curve in how to divert fluids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

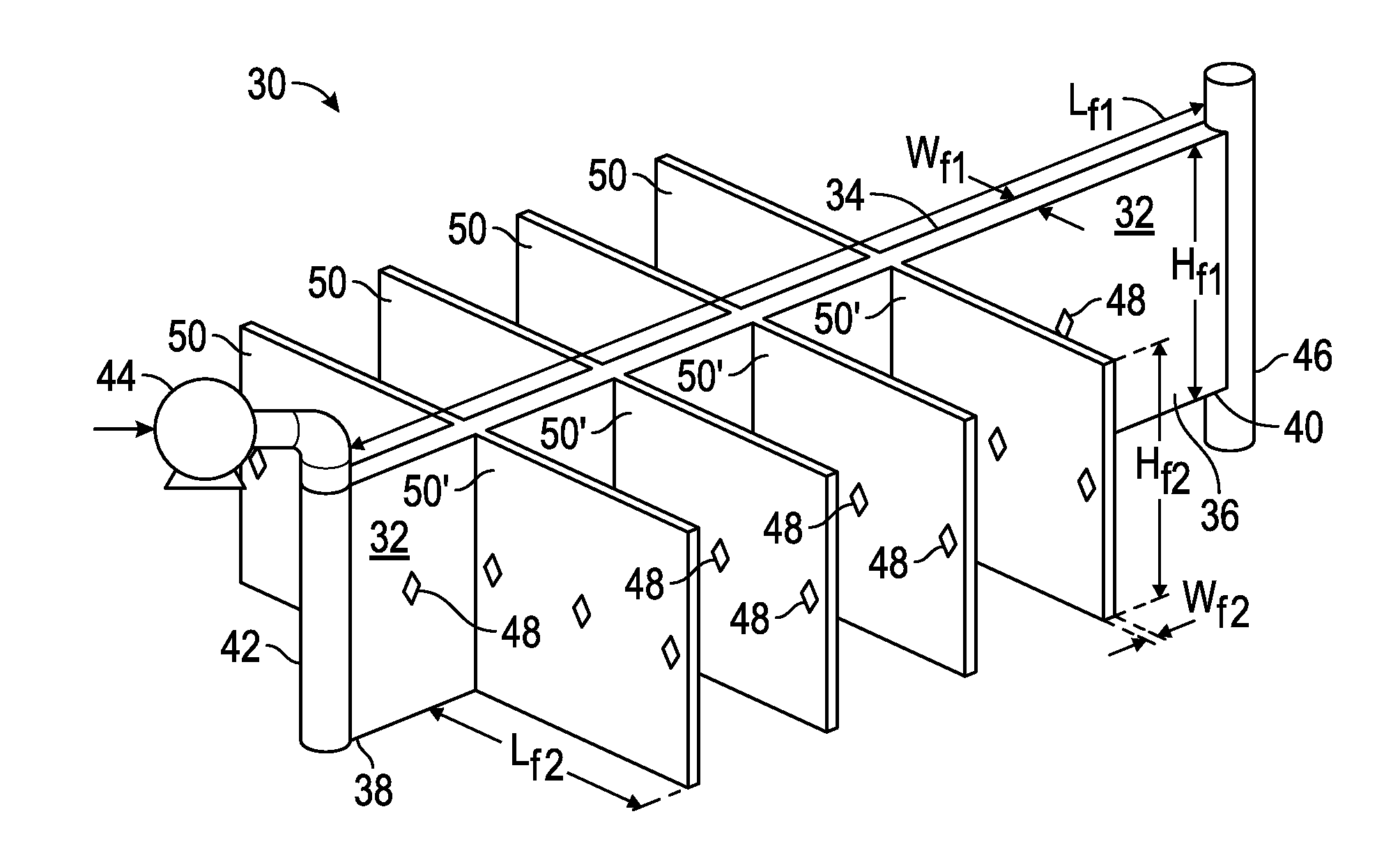

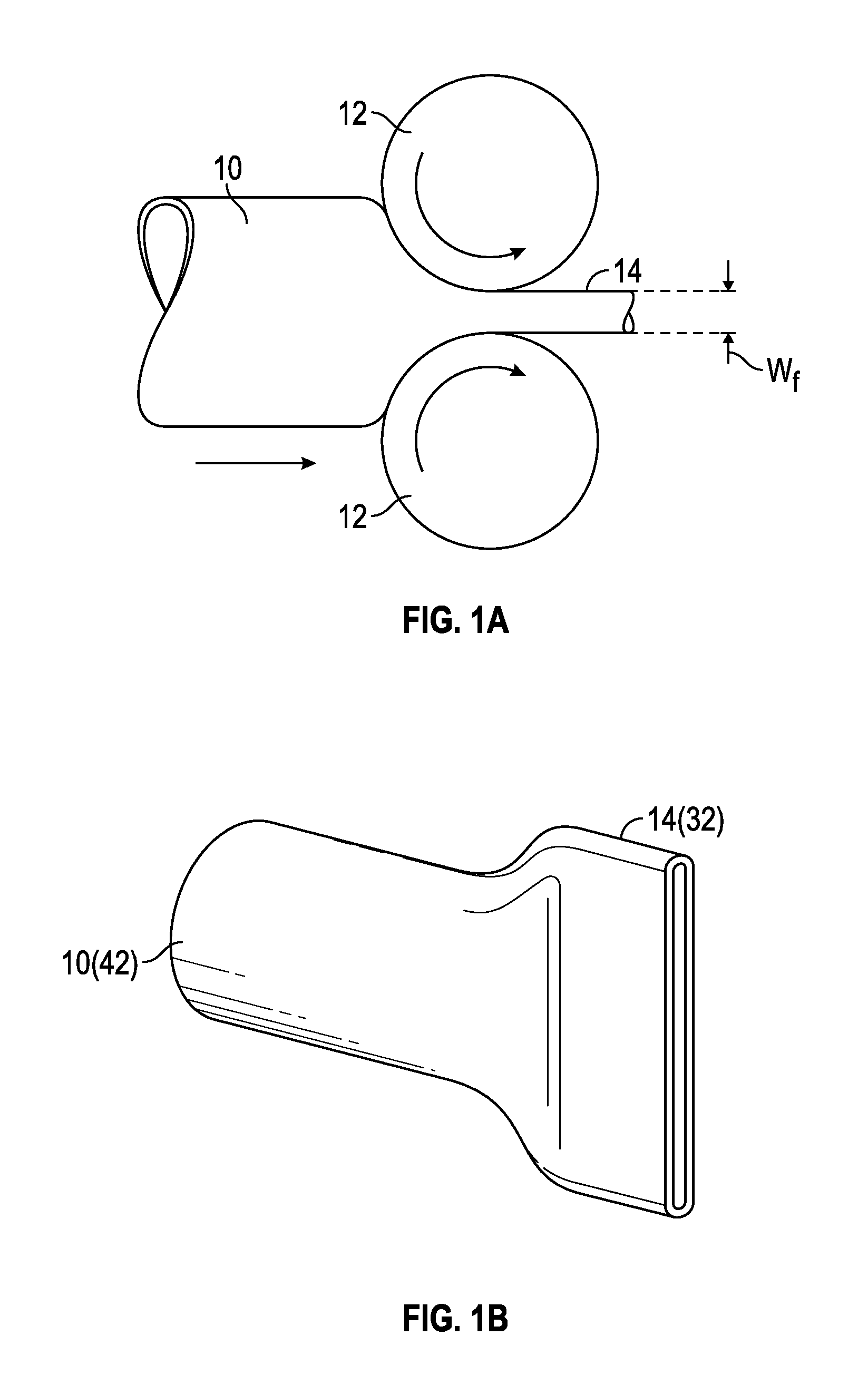

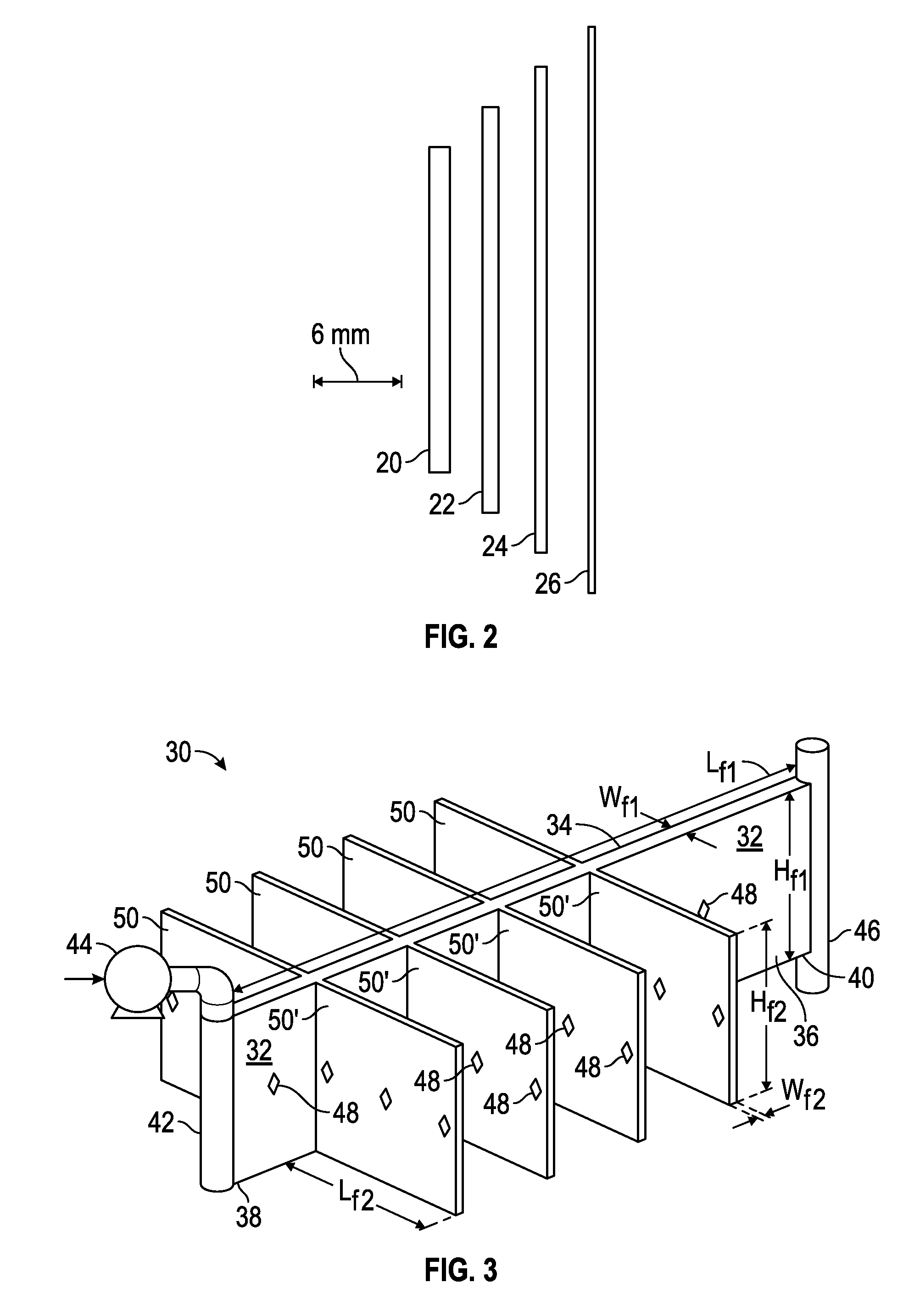

[0021]A method and apparatus have been discovered that may be used to experimentally evaluate the flow of treatment fluids within narrow shale-type fractures. The method is based on artificially creating varying width, height and length “fractures” by flattening tubing (or pipes), or otherwise constructing conduits with relative large height / width ratios, and connecting them to resemble fractures.

[0022]Several material and manufacturing methods may be employed to produce flatten tubing with different gauged internal widths, as described and shown in the Figures. Alternatively, fracture-like conduits may be constructed from multiple parts. A wide range of equipment may be configured to build a shale fracture flow apparatus contemplated herein including, but not necessarily limited to, flow system pumps, accumulators, connections, pressure transducers, pressure discs, gauged cross-intersections, fluid collection chambers, thermo-couples, automation hardware and software, and the like....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com