Composite type fracture test loading device

A technology of fracture test and loading device, which is applied in the direction of measuring device, applying stable tension/pressure to test material strength, instruments, etc., which can solve the problems affecting the acquisition of test data and theoretical analysis research, non-continuous adjustment of angle, inconvenient assembly and disassembly, etc. Problems, easy to manufacture, avoid inconvenient clamping and disassembly, and convenient assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

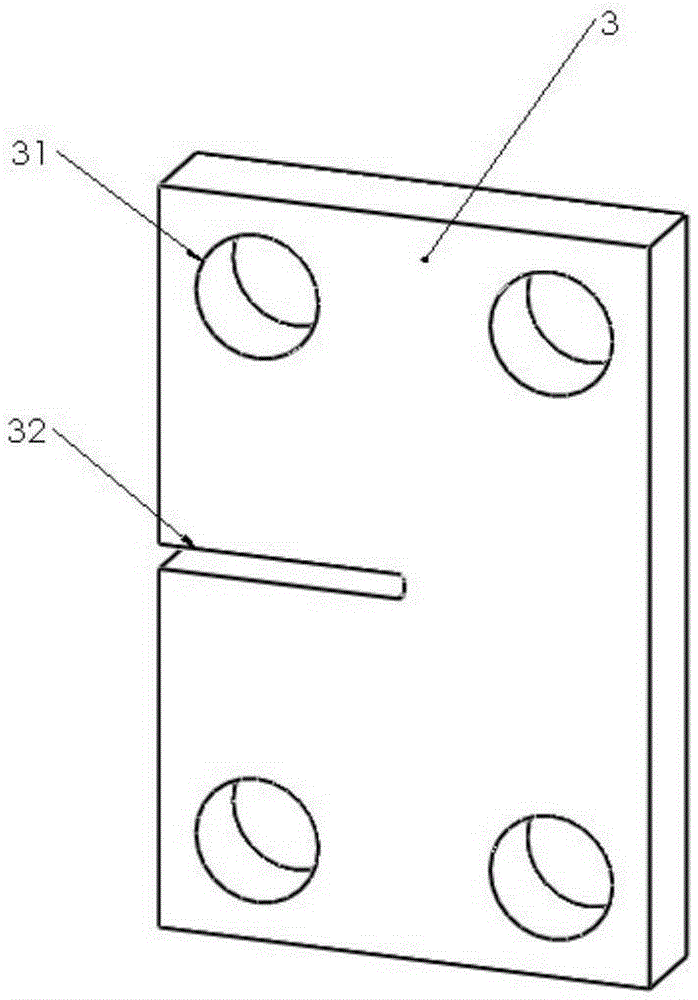

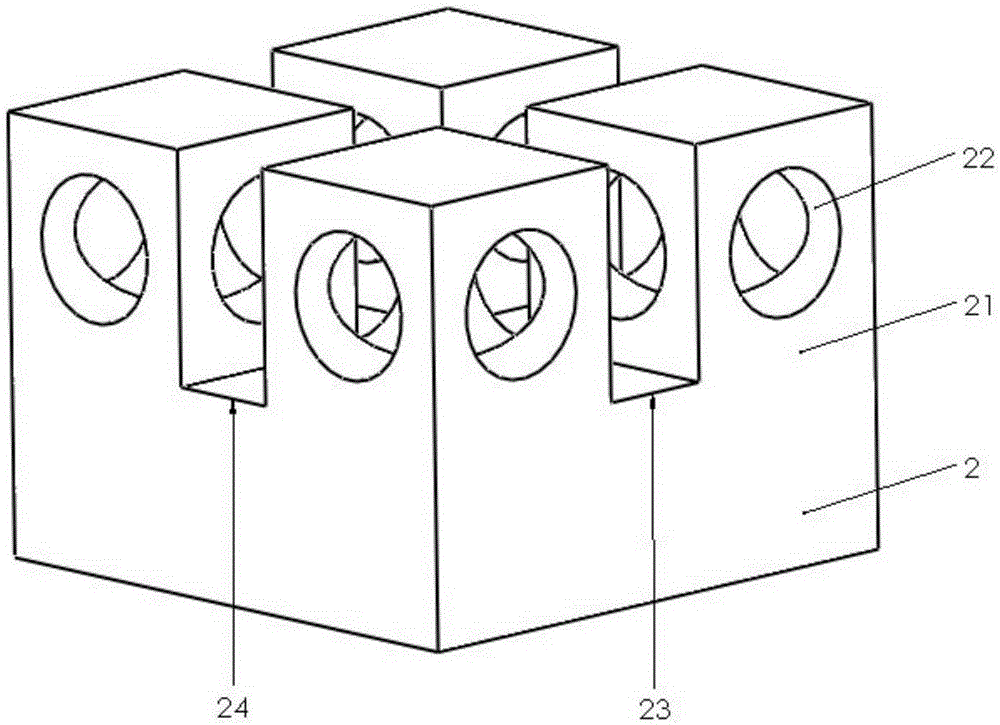

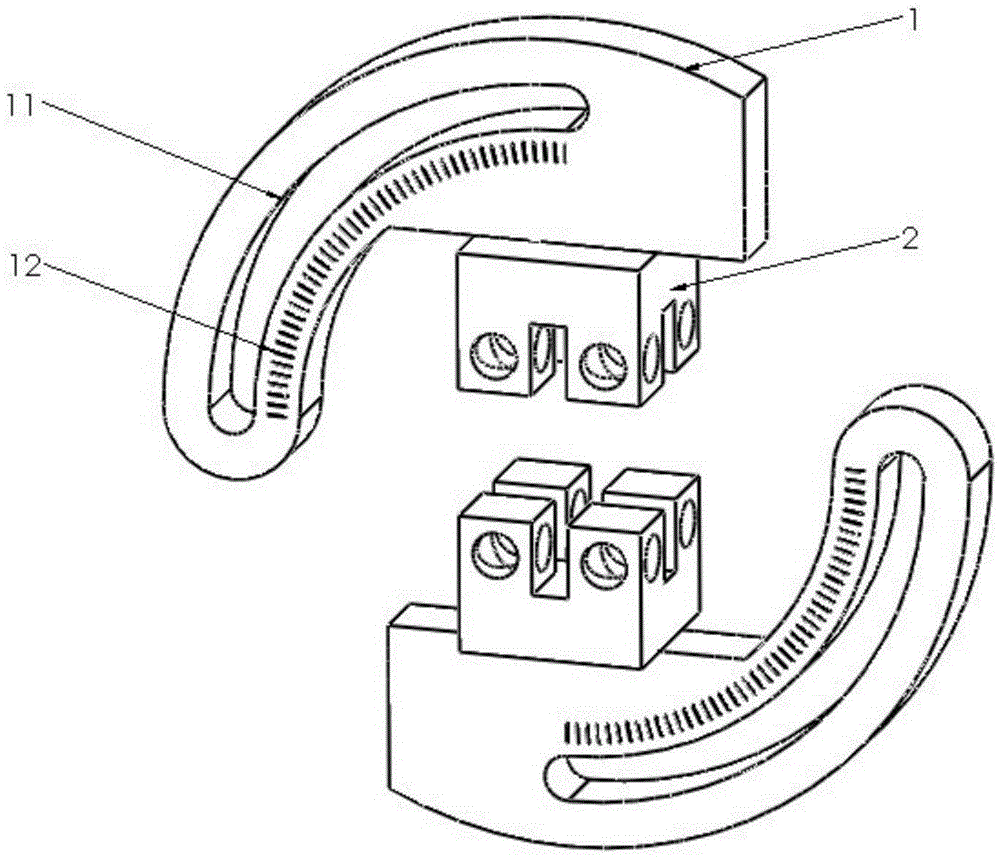

[0019] Such as Figure 1-3 As shown, a composite fracture test loading device includes a pair of C-shaped arc plates 1 arranged up and down opposite and coplanar, and the central angle of the C-shaped arc plates 1 is 90°. The C-shaped arc plate 1 is provided with an arc chute 11 that is fixed to the testing machine by a set bolt, and the position corresponding to the arc chute 11 on the C-shaped arc plate 1 is provided with an experimental Angle scale 12 of the included angle between the mechanical load and the normal direction of the crack surface 32 of the test piece, fixing the positioning bolts to different positions of the arc chute 11, can realize the adjustment of the included angle between the mechanical loa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com