Triaxial test three-dimensional deformation reconstruction and measurement method

A triaxial test and three-dimensional deformation technology, applied in the direction of measuring devices, instruments, optical devices, etc., to achieve the effect of reconstruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

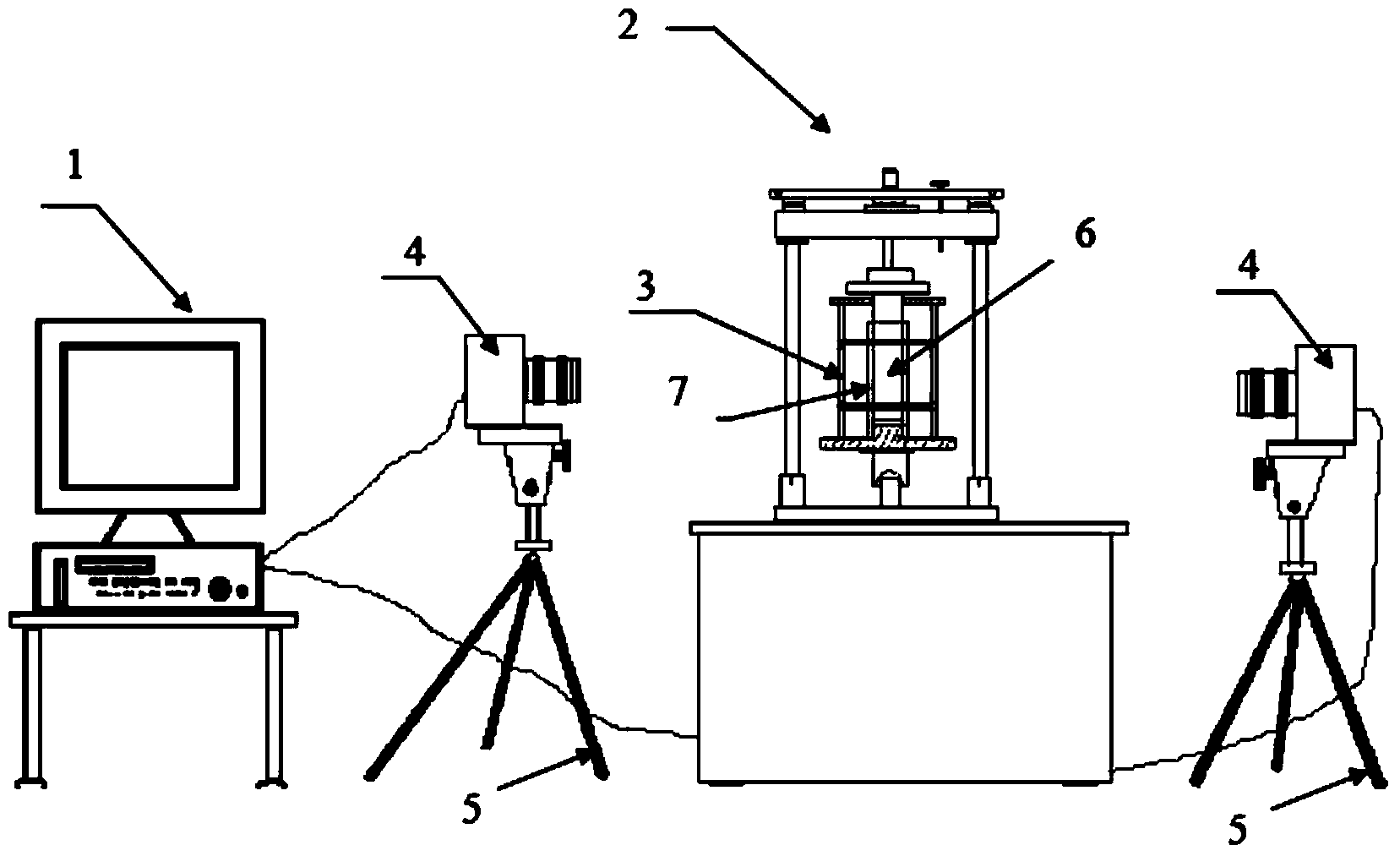

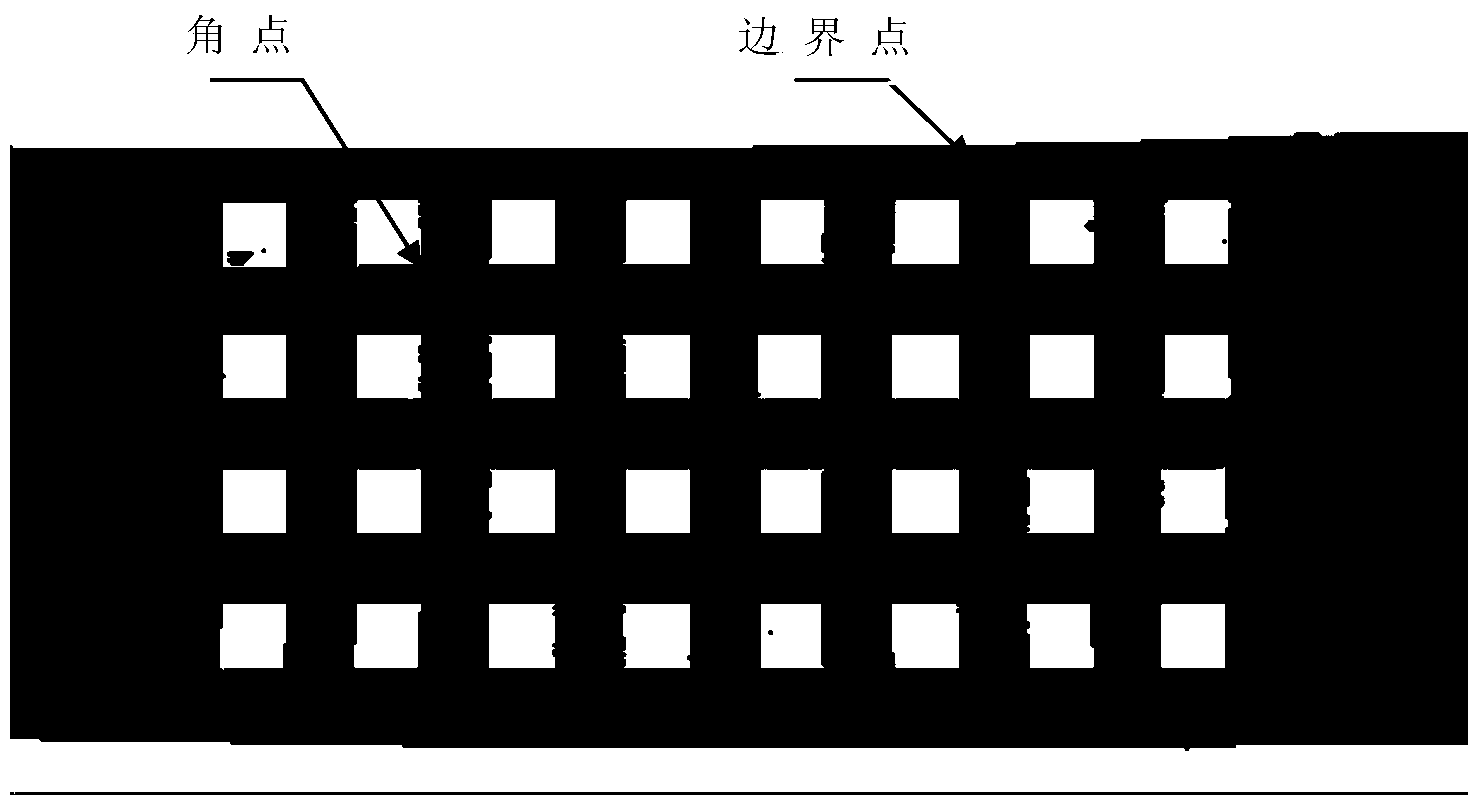

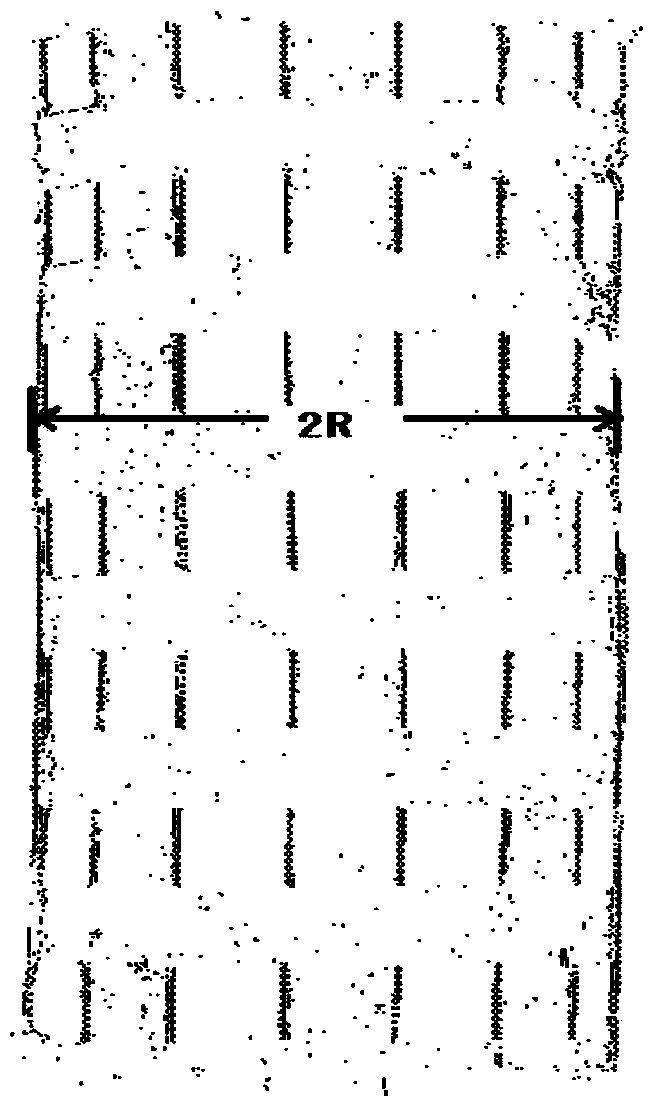

[0019] Such as figure 1 As shown, the scheme for realizing three-dimensional measurement of the present invention includes the following equipment: computer control acquisition system 1, triaxial instrument 2, square triaxial pressure chamber 3, two CCD cameras 4, two tripods 5, triaxial sample 6, The rubber film 7 engraved with black and white squares, the size of the squares is 7mmx7mm. The triaxial instrument is a TSZ10-1.0 strain-controlled triaxial instrument produced by Nanjing Soil Instrument Factory. The square pressure chamber is made of plexiglass material, the wall thickness is 2.0cm, and the side length is 11.0cm. The CCD camera adopts the DH-HV3151UC camera produced by Daheng Image, with a pixel resolution of 2048×1536. The lens is an adjustable focus lens with a maximum focal length of 16mm produce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com