Proppant placement

a proppant and placement technology, applied in the direction of fluid removal, chemistry apparatus and processes, borehole/well accessories, etc., can solve the problem of non-uniformity of the proppant pack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

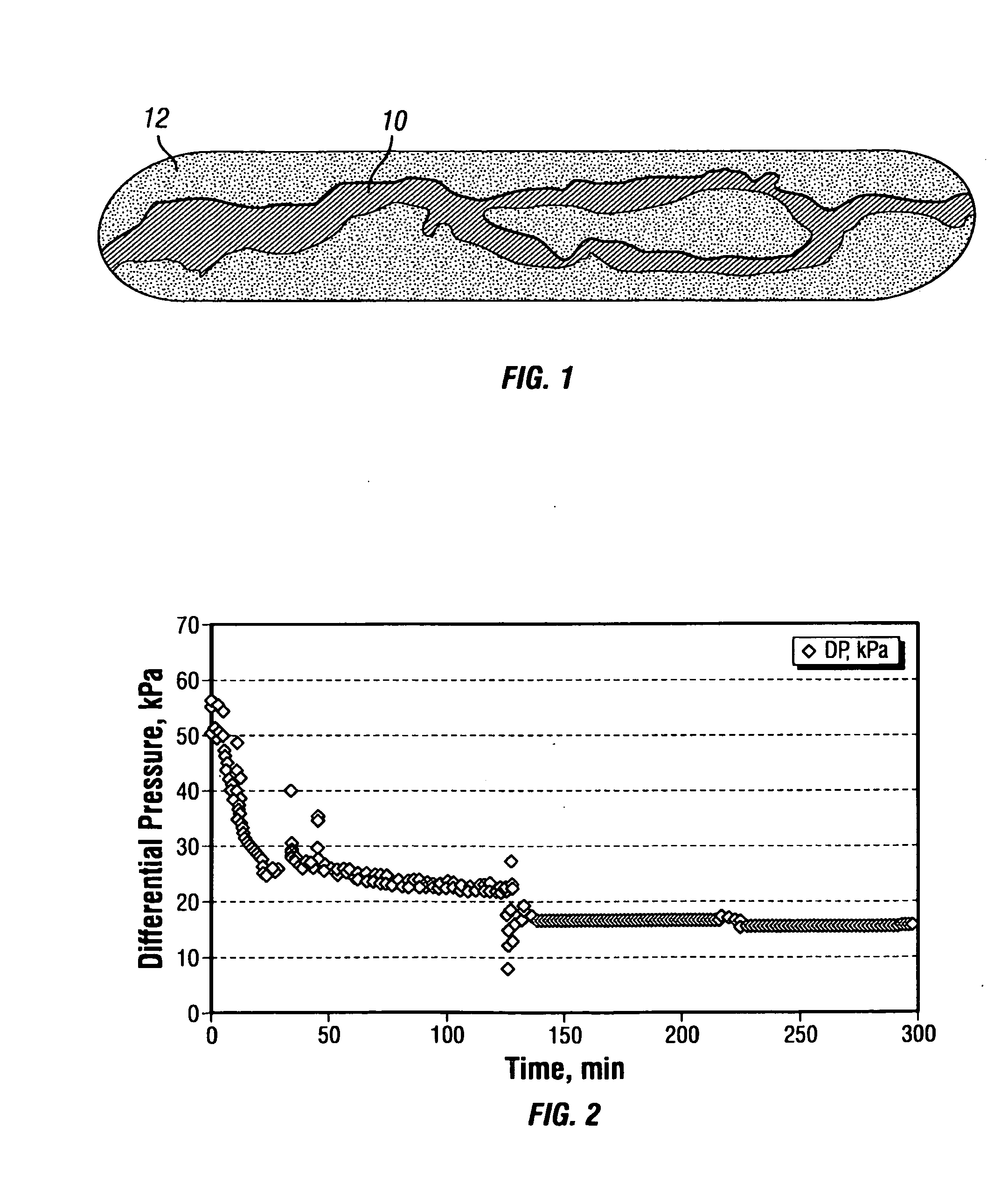

[0120]Hydraulic differential pressure was measured in a silica flour pack while pumping potassium chloride brine (2 wt %) at a flow rate of 0.5 ml / min. The silica flour comprised 99.5% quartz, measured by X-ray diffraction. The silica flour consisted of particulates less than 44 microns (325 US mesh) with median diameter of 18.4 microns. The loading comprised 4.9 kg / m2 (2.0 lb / ft) in an API recommended conductivity cell between two metal cores under closure stress of 13.8 MPa (2000 psi). FIG. 1 is a schematic drawing of a typical branched network channel 10 formed around an island in the silica flour pack 12 by washout in the conductivity cell. FIG. 2 shows a time-trace of the pressure drop in the silica flour pack and illustrates the slow equilibration rate to steady state. The spikes seen in FIG. 2 are due to washout of silica flour from the pack.

example 2

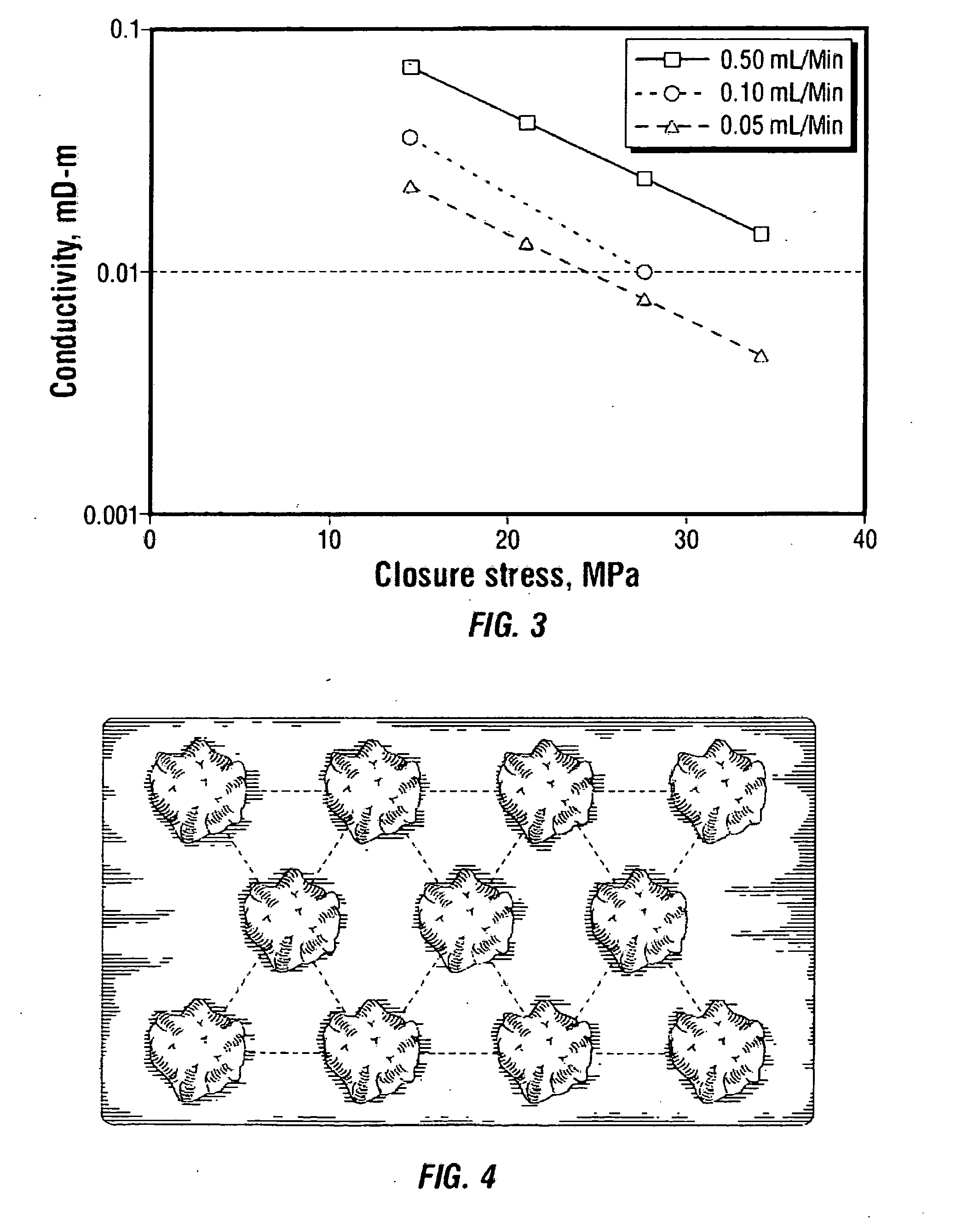

[0121]Conductivity of muscovite mica packs formed from mica with a median particle diameter of 120 microns was measured by means of a Chandler Engineering FRT Model 6100 formation response tester in a split-core set-up. The mica was loaded uniformly at 0.5 kg / m (0.1 lb / ft) between two metal cores, which were compressed with closure stresses of 13.8, 20.7, 27.6, and 34.5 MPa (2000, 3000, 4000 and 5000 psi). Potassium chloride brine (2 wt %) was pumped through the cell with flow rates of 0.05, 0.1 and 0.5 ml / min. The steady state conductivity data for the mica packs are presented in Table 1 and shown graphically in FIG. 3. The formation of channels in the mica packs was visually confirmed upon disassembly of the conductivity cell, and it was seen that the higher flow rates resulted in relatively larger channel formation.

TABLE 1Conductivity of uniform mica packs at 0.5 kg / m.Closure Stress, MPa (psi)Flow Rate,13.8 (2000)20.7 (3000)27.6 (4000)34.5 (5000)ml / minConductivity, mD-m (mD-ft)0....

example 3

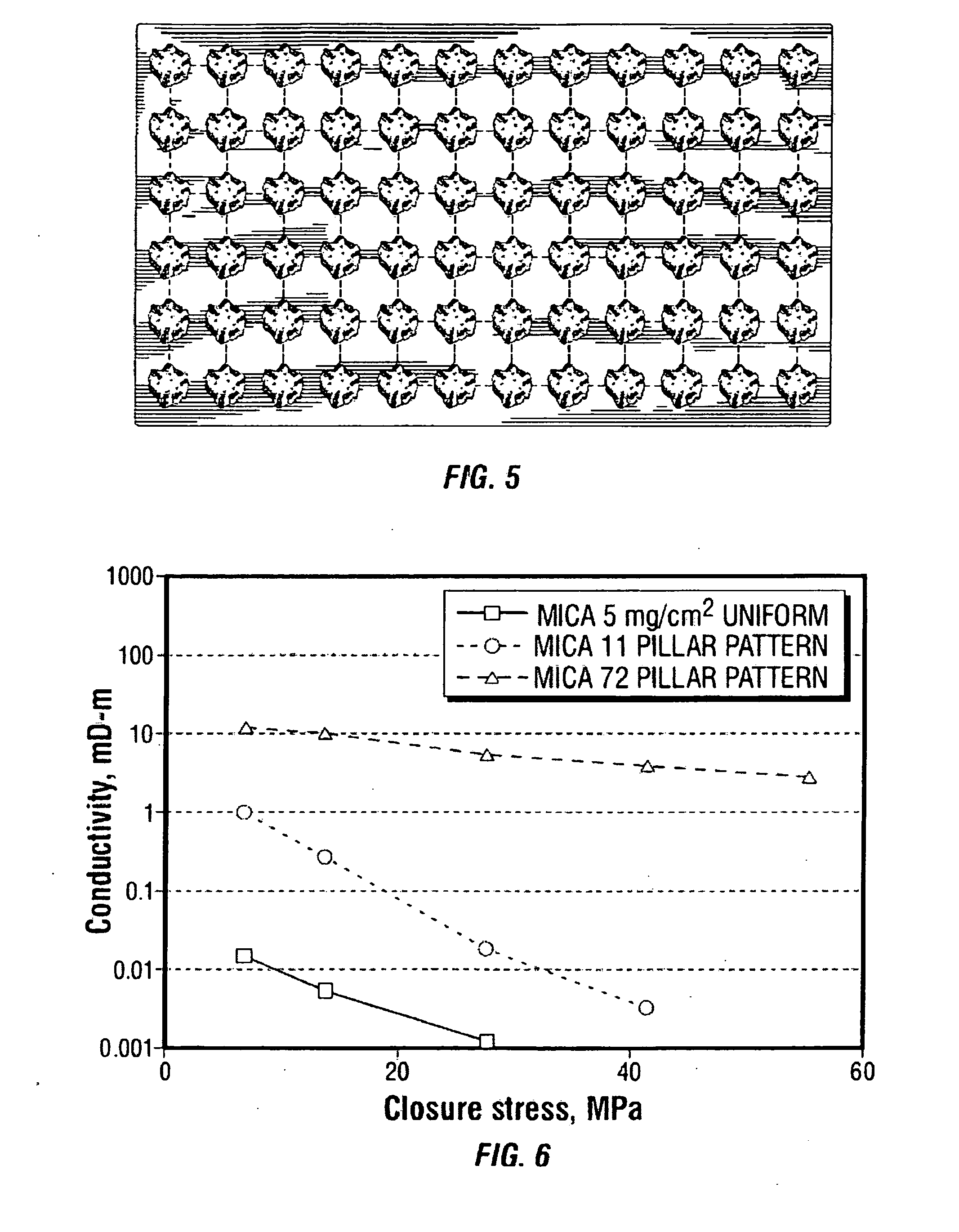

[0122]Conductivity of muscovite mica packs formed from mica with a median particle diameter of 105 microns was measured in a split-core set-up.

[0123]The mica was loaded uniformly or in pillars at 5 kg / m (0.01 lb / ft) between two Mancos shale cores, which were compressed with closure stresses of 3.4, 6.9, 13.8, 27.6, 41.4 and 55.2 MPa (500, 1000, 2000, 4000, 6000 and 8000 psi). The pillars were arranged in a triangular pattern of 11 pillars in longitudinal rows of 4, 3 and 4 pillars as seen in FIG. 4, or in a 6 by 12 square pattern of 72 pillars, as seen in FIG. 5. Potassium chloride brine (2 wt %) was pumped through the cell with flow rates of 0.05-0.200 ml / min. The steady state conductivity data for the mica packs are presented in Table 2 and shown graphically in FIG. 6. The placement of the mica in the pillar arrangement obtained a relatively higher conductivity than the uniform mica placement. The placement of the mica in the 72-pillar configuration had a higher conductivity relat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com