Fractured shale gas-water two-phase flow fracture conductivity evaluation device and method

A technology for conductivity and evaluation devices, which is applied in the direction of measuring devices, mining fluids, earthwork drilling, etc., can solve the problems that cannot take into account the influence of shale micro-fractures on conductivity, and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

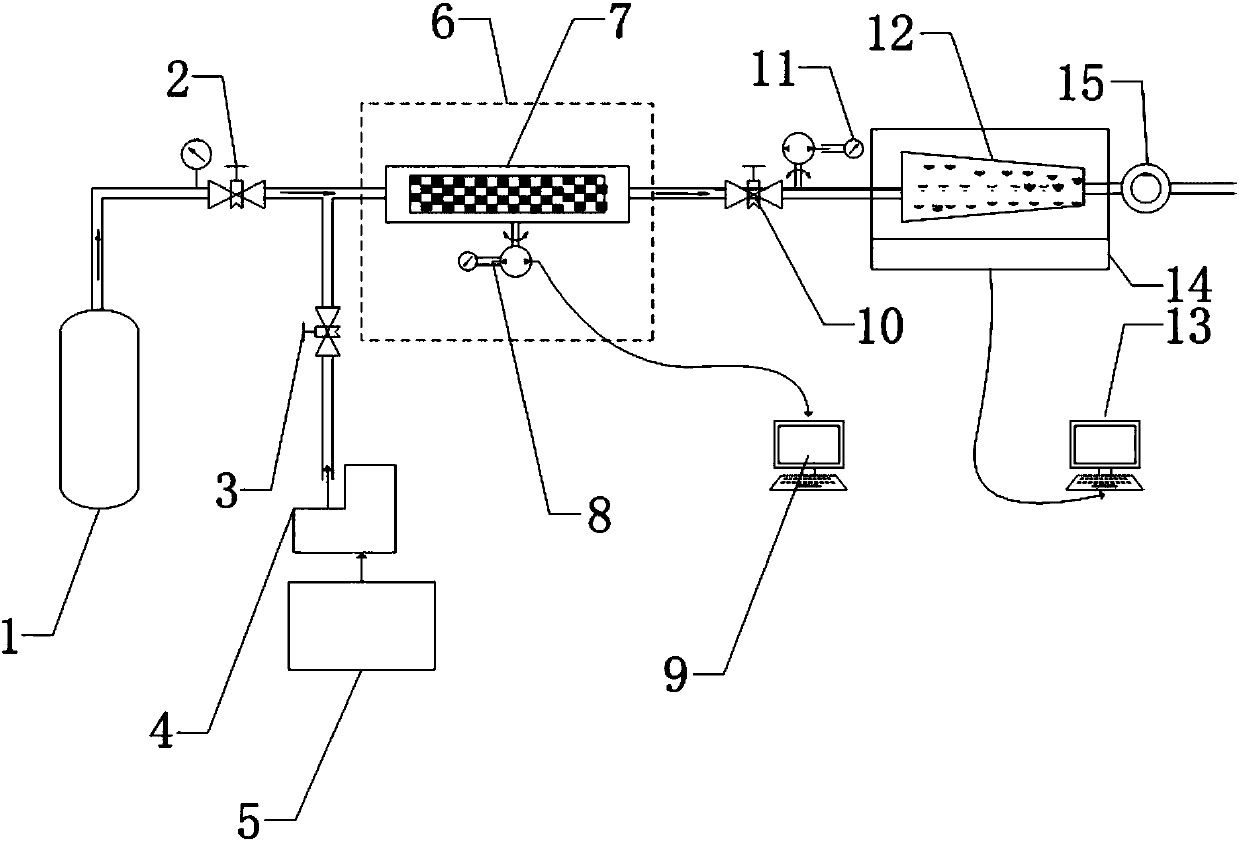

Method used

Image

Examples

Embodiment 1

[0048] Cut the shale test sample into a cylinder, perform fracturing, and dry the cut shale test sample at 102°C for 24 hours;

[0049] Obtain the cross-sectional area and length of the dried shale test sample. After drying, coat the side of the cylindrical core with epoxy silica gel, dry it, weigh it, and prepare for the experiment;

[0050] The temperature of thermostat 6 is set to 45°C;

[0051] Put the test sample into the core holder 7; in order to explore the hydration reaction of the shale fracture after water invasion, set the back pressure pump 18 at a low confining pressure, the confining pressure value is 2MPa, in order to prevent the shale from creeping Influencing factors, start the experiment after the confining pressure is stable for 12 hours, and measure the initial permeability through the gas injection seepage system;

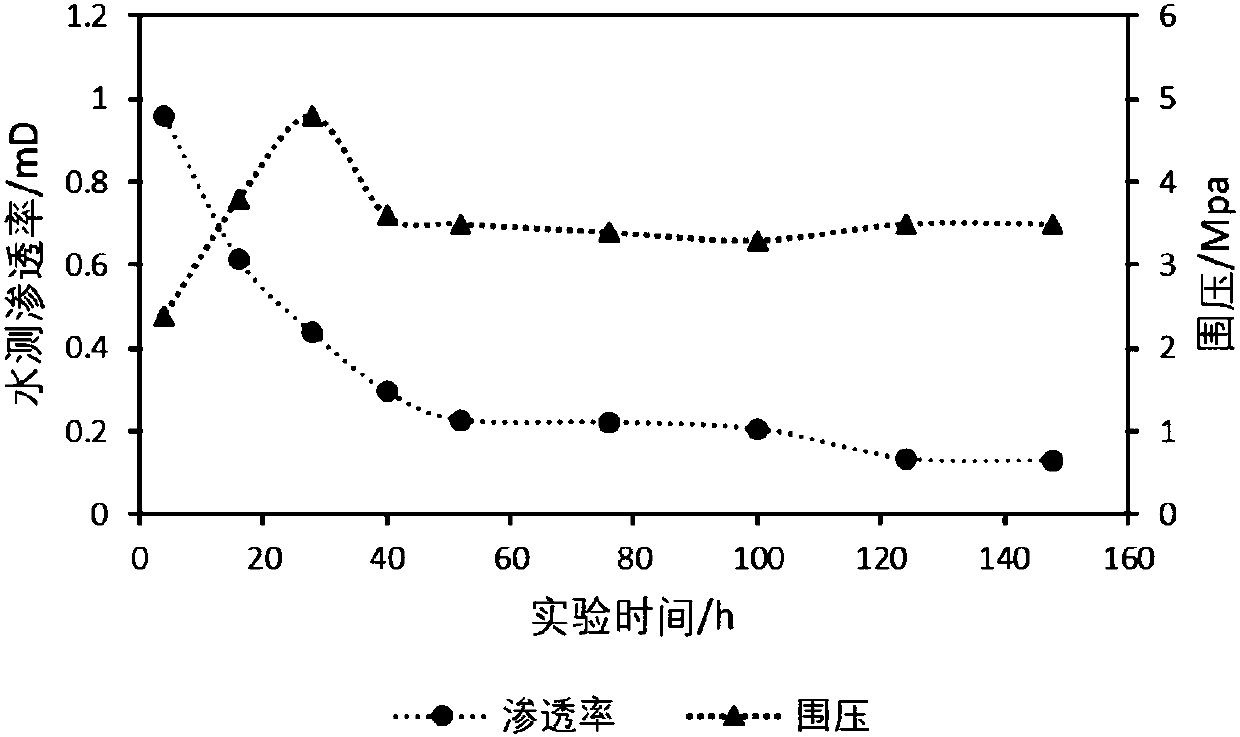

[0052] Water injection stage:

[0053] Close valve 2 and set constant speed and constant pressure pump 4 for constant pressure injection, s...

Embodiment 2

[0055] The first step: experimental preparation stage:

[0056] Cut the shale test sample into a cylinder, perform fracturing, and dry the cut shale test sample at 102°C for 24 hours;

[0057] Obtain the cross-sectional area and length of the dried shale test sample. After drying, coat the side of the cylindrical core with epoxy silica gel. After drying, weigh and prepare for the experiment;

[0058] The temperature of thermostat 6 is set to 45°C;

[0059] Put the rock sample into the three-axis core holder 7; set the back pressure valve 10 to 2MPa, and set the confining pressure to 12MPa for the back pressure pump 18. In order to prevent the factors affecting shale creep, wait for the confining pressure to stabilize for 12 hours After that, the experiment was started, and the initial permeability was measured through the gas injection seepage system;

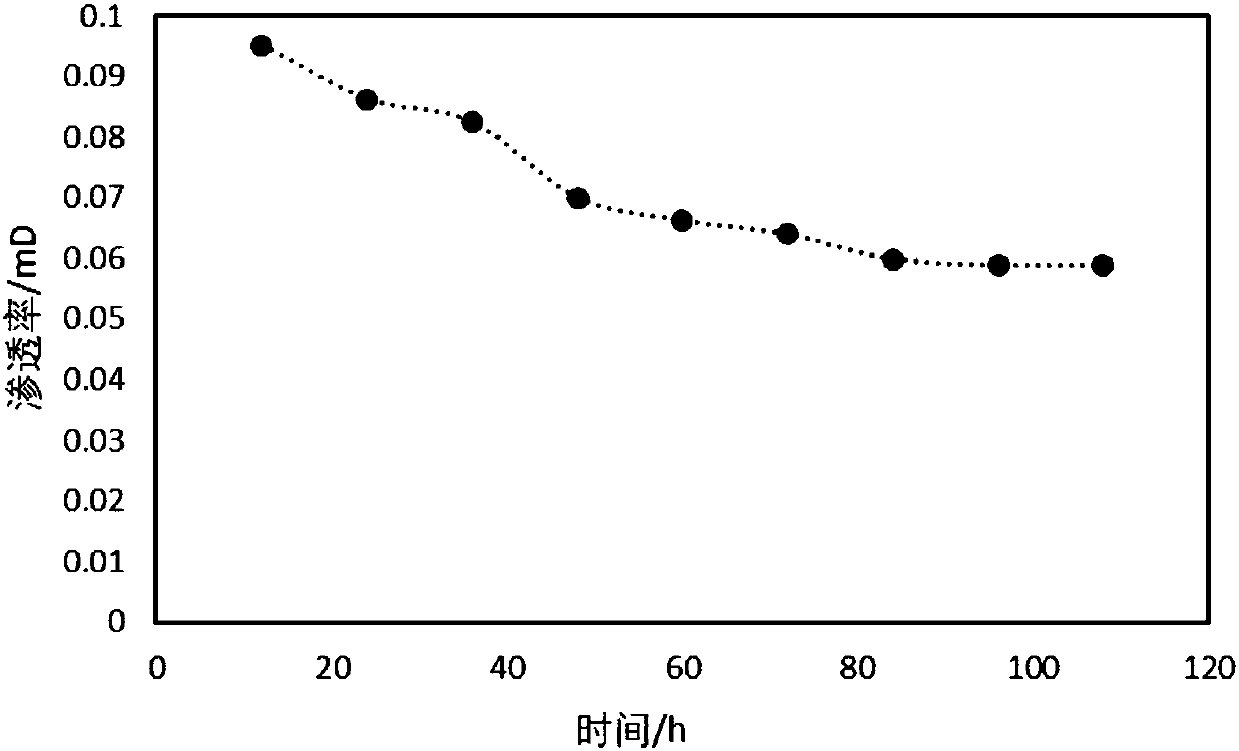

[0060] The second step: water injection stage:

[0061] Close valve 2 and set constant speed and constant pressure pump 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com