Well cementation oil-based slurry flushing liquid and preparation method thereof

An oil-based mud and flushing fluid technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as difficulty in cleaning and affecting the quality of cementing at the two interfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

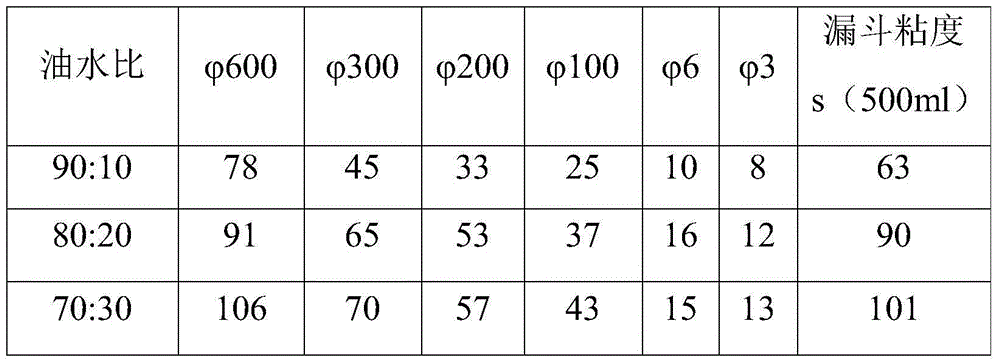

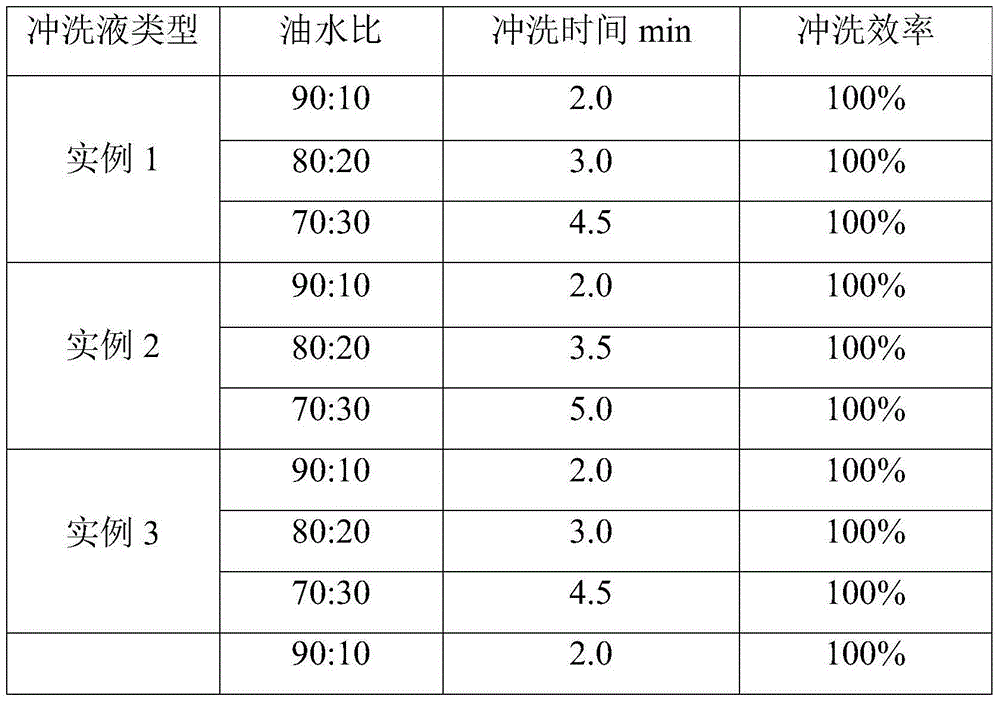

Embodiment 1

[0036] Add 0.2 parts of scleroglucan to 100 parts of water and stir for 50 minutes, then add 2 parts of polyoxyethylene alkylamine in turn (R1 is C16 alkyl; m, n=10), 3 parts of alkylphenol polyoxyethylene ether (R2 is an alkyl group of C9; x=10), 7 parts of alkyl alcohol polyoxyethylene ether carboxylate R 9 O(CH 2 CH 2 O) y CH 2 COOH (R9 is C16 alkyl; y=11), 4 parts of alkyl dihydroxyethyl carboxybetaine (R4 is C16 alkyl), 1.5 parts of Span 80, 1.5 parts of Tween 80.

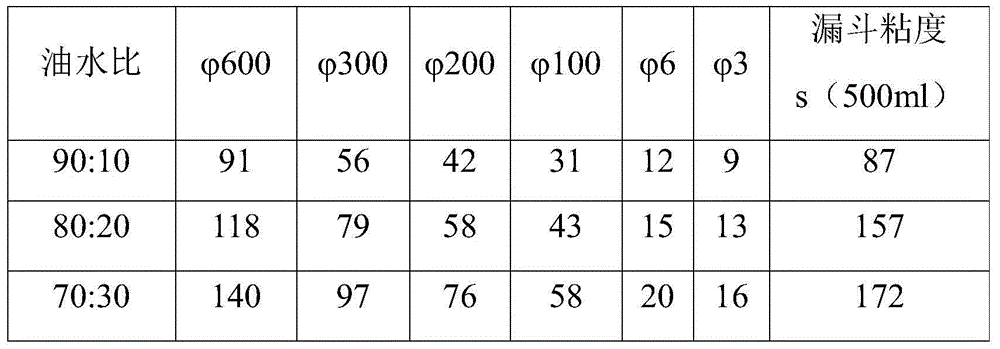

example 2

[0038] Add 3.5 parts of Brunei gum to 100 parts of water and stir for 40 minutes, then add 3 parts of polyoxyethylene alkylamine in turn (R1 is C12 alkyl; m, n=8), 3 parts of alkylphenol polyoxyethylene ether (R2 is an alkyl group of C8; x=10), 5 parts of alkyl alcohol polyoxyethylene ether carboxylate R 9 O(CH 2 CH 2 O) y CH 2 COOH (R9 is C12 alkyl; y=7), 3 parts of alkyl dimethyl sulfonate betaine (R5 is C16 alkyl), 1 part of alkyl diisethionate betaine molecular formula is (R6 is C16 alkyl), 1.5 parts of Span 80, 1.5 parts of Tween 80.

example 3

[0040] Add 2.0 parts of Brunei gum to 100 parts of water and stir for 40 minutes, then add 3 parts of polyoxyethylene alkylamine in turn (R1 is C10 alkyl; m, n=6), 1 part of alkylphenol polyoxyethylene ether (R2 is an alkyl group of C12; x=12), 8 parts of alkyl alcohol polyoxyethylene ether carboxylate R 9 O(CH 2 CH 2 O) y CH 2 COOH (R9 is an alkyl group of C8; y=5), 5 parts of alkyl dimethyl carboxylate betaine molecular formula is (R3 is C12 alkyl), 2.0 parts of Span 80, 2.0 parts of Tween 80.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com