SBS polymer modified emulsified asphalt and preparation method

A technology of emulsified asphalt and modified asphalt, which is applied in the direction of building structure, building components, building insulation materials, etc., can solve the problems of SBS polymers that are difficult to blend with emulsifiers, unstable materials and product properties, and difficult emulsification. Achieve the effects of reducing road maintenance costs, good high temperature and anti-rutting, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

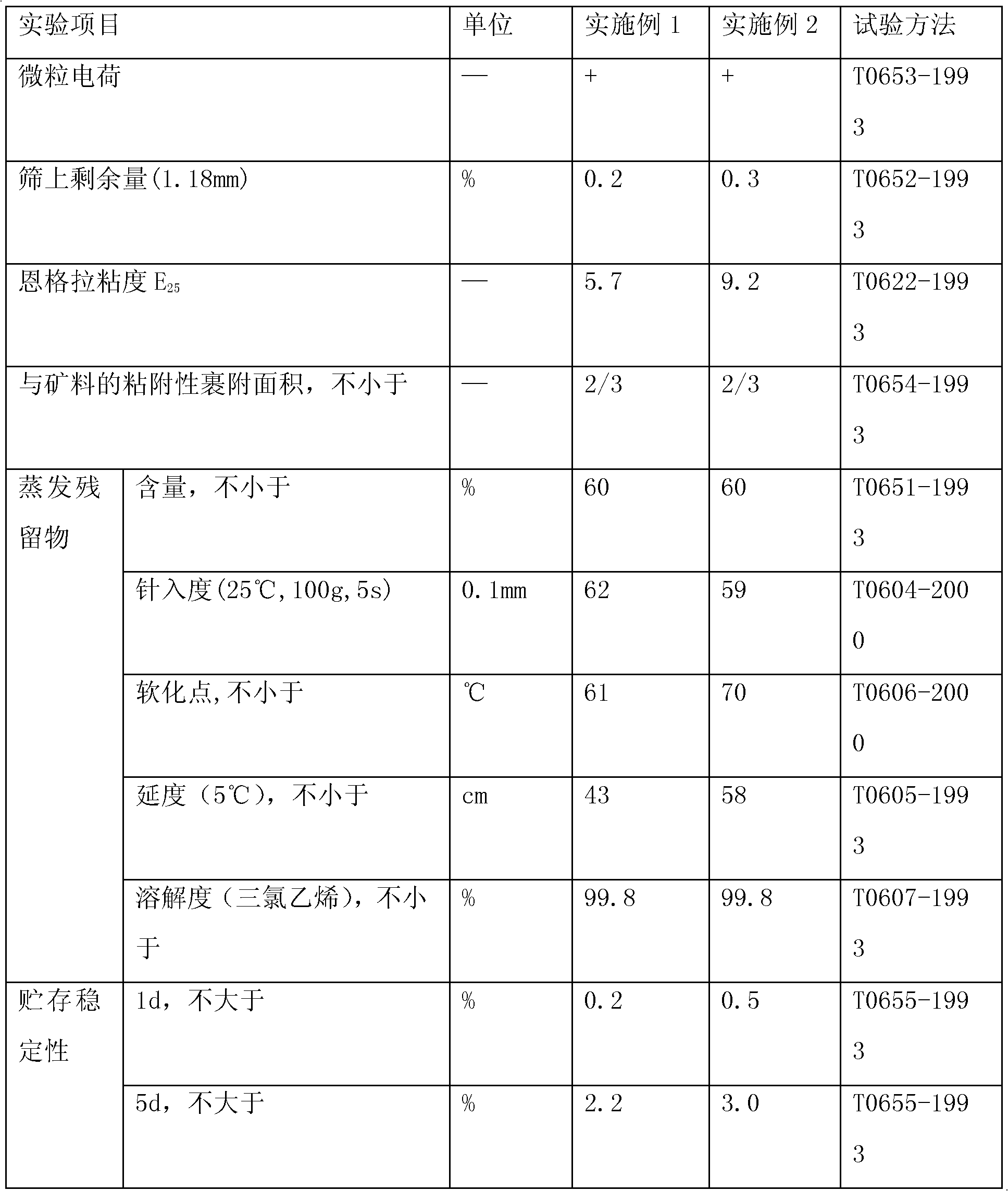

Examples

Embodiment 1

[0017] In this example, the SBS polymer modified emulsified asphalt is prepared from the following mass percentage of raw materials: SBS polymer modified asphalt with a mass content of 3.5% SBS polymer modifier 60%, and cationic asphalt emulsifier is octadecane Trimethylammonium chloride 3% and octadecyl dimethyl hydroxyethyl ammonium chloride 1% are compounded. The compound emulsion stabilizer is a mixture of ammonium chloride 0.5% and sodium carboxymethyl cellulose 0.25% , Hydrochloric acid 0.31% and water 34.94%.

[0018] The specific preparation method is:

[0019] (1) Mix the SBS polymer modifier with the base asphalt at a temperature of 160°C, add it to the colloid mill, grind and stir for 2 hours to obtain the SBS polymer modified asphalt;

[0020] (2) Add cationic asphalt emulsifier into water at 40°C to dissolve it, add acid to adjust the pH of the emulsion to 4, and then add complex emulsion stabilizer to obtain soap;

[0021] (3) Set the temperature of the colloid mill at ...

Embodiment 2

[0023] In this embodiment, the SBS polymer modified emulsified asphalt is prepared from the following mass percentages of raw materials: SBS polymer modifier with a mass content of 5.5% SBS polymer modified asphalt with 60%, and cationic asphalt emulsifier with octadecane Compounded with 2% trimethyl ammonium chloride and 2% octadecyl dimethyl hydroxyethyl ammonium chloride, the compound emulsion stabilizer is a mixture of 0.25% calcium chloride and 0.03% polyacrylamide, 0.31 hydrochloric acid % And 35.41% of water.

[0024] The specific preparation method is:

[0025] (1) Mix the SBS polymer modifier with the base asphalt at a temperature of 168°C, add it to the colloid mill, grind and stir for 2 hours to obtain the SBS polymer modified asphalt;

[0026] (2) Add cationic asphalt emulsifier into water at 45°C to dissolve it, add acid to adjust the pH of the emulsion to 3, and then add complex emulsion stabilizer to obtain soap;

[0027] (3) Set the temperature of the colloid mill at ...

Embodiment 3

[0029] In this embodiment, the SBS polymer modified emulsified asphalt is prepared with the following mass percentage of raw materials: SBS polymer modified asphalt 45% with 4.0% SBS polymer modifier mass content, and hexadecane as the cationic asphalt emulsifier 3.5% trimethylammonium bromide and 1% alkyl diquaternary ammonium salt are compounded. The composite emulsion stabilizer is a mixture of 0.2% ammonium chloride and 0.25% gelatin, 0.35% hydrochloric acid and 49.7% water.

[0030] The specific preparation method is:

[0031] (1) Mix the SBS polymer modifier with the base asphalt at a temperature of 165°C, add it to the colloid mill, grind and stir for 2 hours to obtain the SBS polymer modified asphalt;

[0032] (2) Add cationic asphalt emulsifier into water at 35°C to dissolve it, add acid to adjust the pH of the emulsion to 5, and then add complex emulsion stabilizer to obtain soap;

[0033] (3) Set the temperature of the colloid mill at 45°C and the pressure at 0.2MPa. After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com