Organosilicon surfactant and preparation method and application thereof

A surfactant and organosilicon technology, applied in the directions of silicon-organic compounds, chemical instruments and methods, transportation and packaging, etc., to achieve good emulsifying effect, convenient use and simple emulsifying process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

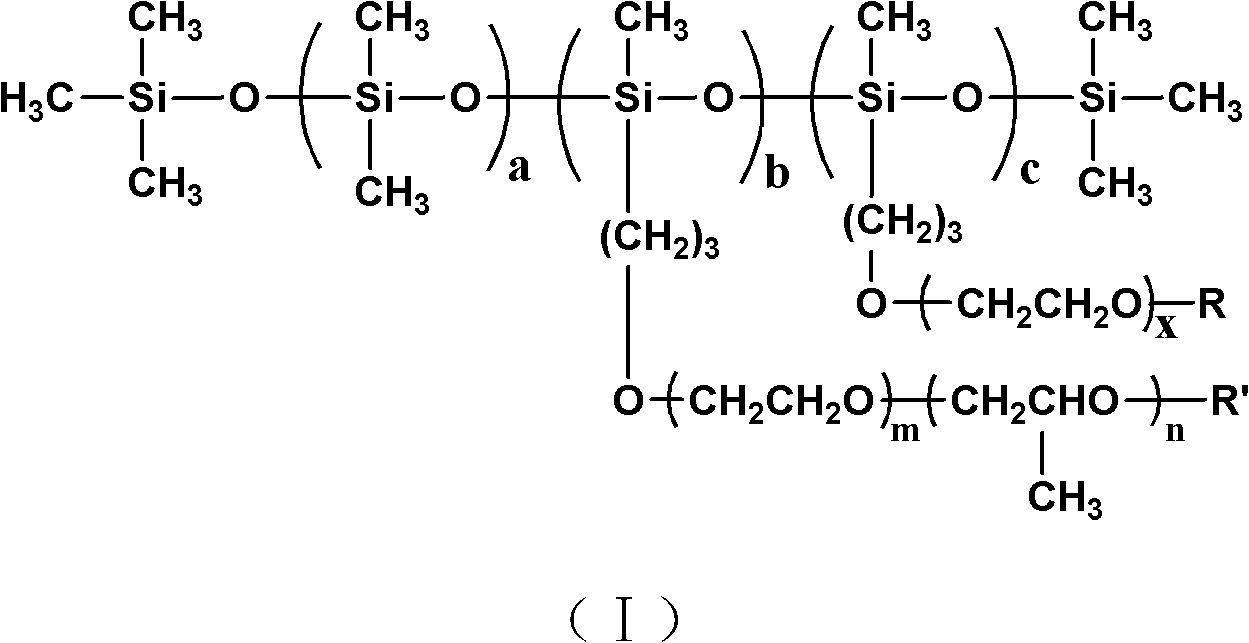

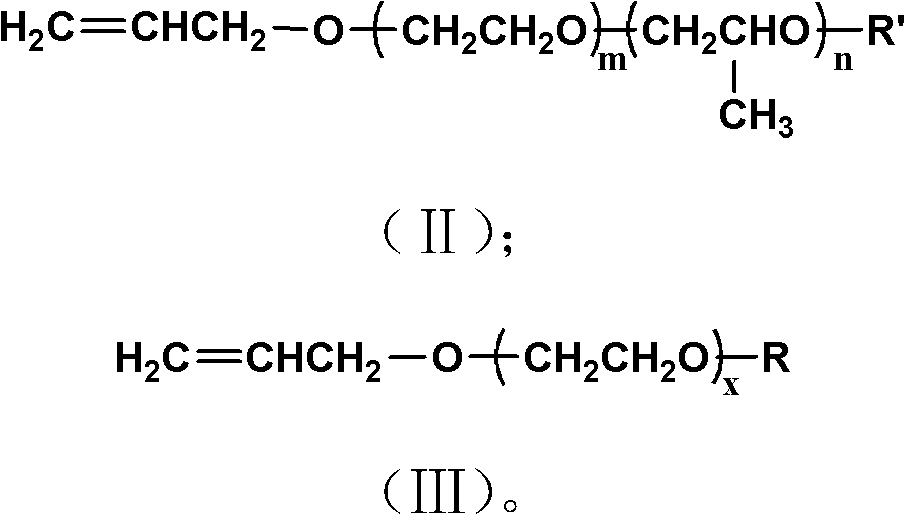

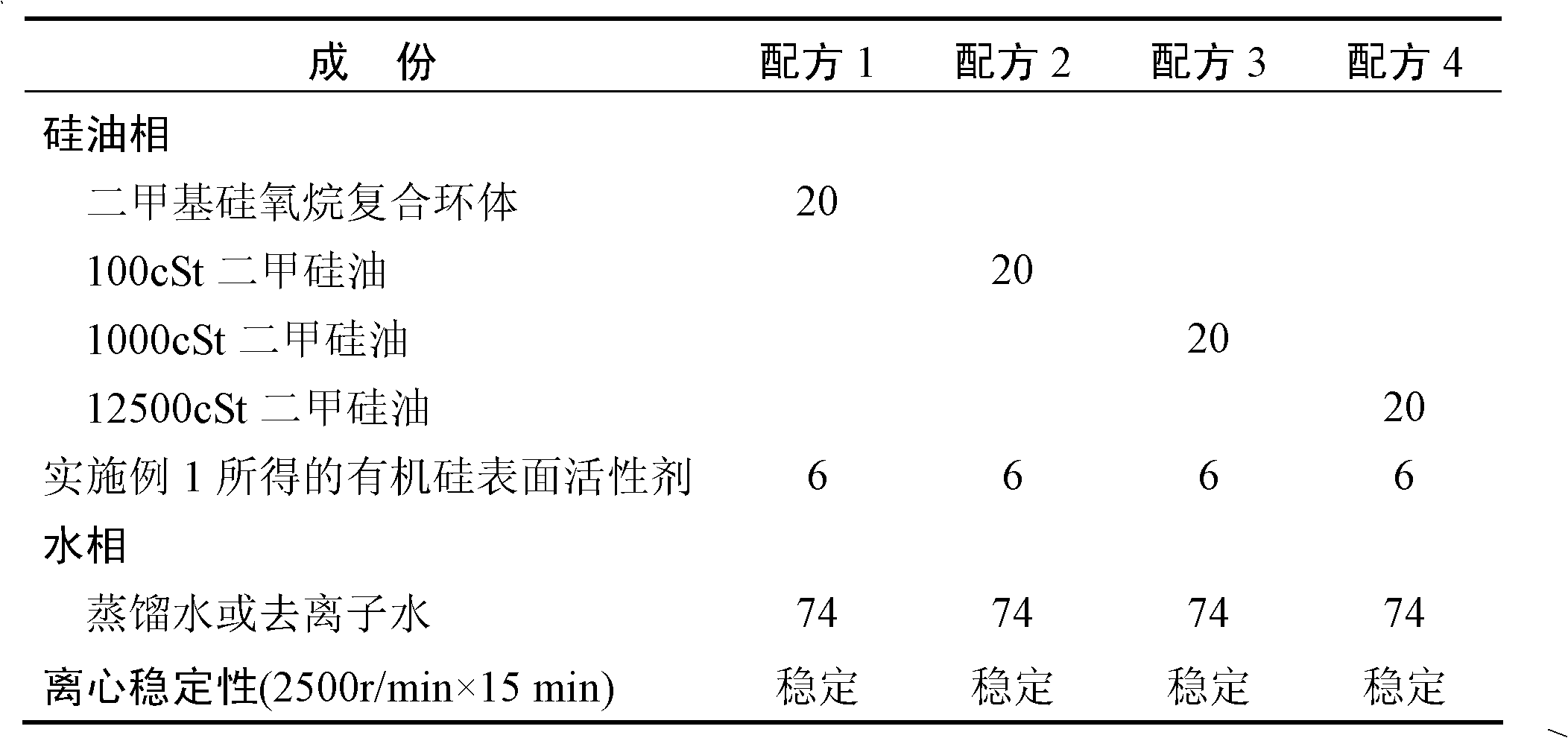

[0030] With stirring device, drum N 2 In the three-necked flask with device and thermometer, add 0.3mol allyl polyether formula (II) (m=10, n=6, R' is C 3 h 7 ), 0.3mol allyl polyether formula (III) (x=9, R is C 12 h 25 ), 0.5 mol of hydrogen-containing silicone oil with a hydrogen content of about 0.3% (mass percentage) (a+b+c≈80, it can be seen that b+c≈18, a:b:c≈62:9:9), Under the protection of nitrogen atmosphere, when the temperature is raised to 80°C, 0.03g of catalyst is added, and the reaction is continued at 120°C to 130°C until the system becomes transparent, and a light yellow transparent silicone surfactant is obtained.

Embodiment 2

[0032] With stirring device, drum N 2 In the three-necked flask with device and thermometer, add 0.2mol allyl polyether (II) (m=38, n=0, R′ is H), 0.3mol allyl polyether (III) (x=3, R is C 16 h 33 ), 0.4mol of hydrogen-containing silicone oil with a hydrogen content of about 0.2% (mass percentage) (a+b+c≈130, it can be seen that b+c≈20, a:b:c≈110:8:12), Under the protection of nitrogen atmosphere, when the temperature is raised to 100°C, 0.03g of catalyst is added, and the reaction is continued to 150°C to 160°C until the system becomes transparent, and a light yellow transparent silicone surfactant is obtained.

Embodiment 3

[0034] With stirring device, drum N 2 In the three-necked flask of device and thermometer, add 0.18mol allyl polyether (II) (m=2, n=30, R' is H), 0.2mol allyl polyether (III) (x=28, R is C 18 h 37 ), 0.32mol of hydrogen-containing silicone oil with a hydrogen content of about 0.35% (mass percentage) (a+b+c≈30, it can be seen that b+c≈20, a:b:c≈22:5:3), Under the protection of nitrogen atmosphere, when the temperature was raised to 90°C, 0.03g of catalyst was added, and the reaction was continued to 130°C-140°C until the system became transparent, and a light yellow transparent silicone surfactant was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com