Novel environment-friendly fire-retardant concentrated solution for hydraulic supports

A technology of hydraulic support and concentrated liquid, applied in the petroleum industry, lubricating composition, etc., can solve problems such as blocking and adhesion, and achieve the effect of high safety factor, easy cleaning and good lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] The concentrated solution for new environment-friendly flame retardant hydraulic supports is prepared from the following raw materials in weight percentage: 20% Turkish red oil, 8% diethanol monoisopropanolamine, 5% zinc dichromate, ethylenediaminetetramethylenephosphine Sodium phosphate 4%, silicone quaternary ammonium salt 7%, diethanol monoisopropanolamine maleate compound 2%, sodium hydroxide 4%, polyisobutenyl succinimide 0.3%, titanate coupling agent 0.4%, barium naphthenate 0.1%, and the balance is water.

[0014] The diethanol monoisopropanolamine maleate compound is prepared by the following method: add diethanol monoisopropanolamine and maleic anhydride in the reactor, add a catalyst, and depressurize to 0.4MPa under stirring conditions , heating, the temperature is controlled at 100°C, the system is maintained at a constant temperature, the acidity of the system is measured every hour, and the reaction stops when there is no significant change in the acid val...

Embodiment 2

[0016] A new type of concentrated solution for environmentally friendly and fire-resistant hydraulic supports is prepared from the following raw materials in weight percentage: Turkish red oil 15%, diethanol monoisopropanolamine 12%, zinc dichromate 8%, ethylenediamine tetramethylene phosphine Sodium phosphate 7%, silicone quaternary ammonium salt 5%, diethanol monoisopropanolamine maleate compound 4%, sodium hydroxide 3%, polyisobutenyl succinimide 0.4%, titanate coupling agent 0.3%, barium naphthenate 0.3%, and the balance is water.

[0017] All the other are with embodiment 1.

Embodiment 3

[0019] The concentrated solution for new environment-friendly and fire-resistant hydraulic supports is prepared from the following raw materials in weight percent: 10% Turkish red oil, 15% diethanol monoisopropanolamine, 10% zinc dichromate, ethylenediaminetetramethylenephosphine Sodium phosphate 10%, silicone quaternary ammonium salt 3%, diethanol monoisopropanolamine maleate compound 5%, sodium hydroxide 2%, polyisobutenyl succinimide 0.5%, titanate coupling agent 0.2%, barium naphthenate 0.5%, and the balance is water.

[0020] All the other are with embodiment 1.

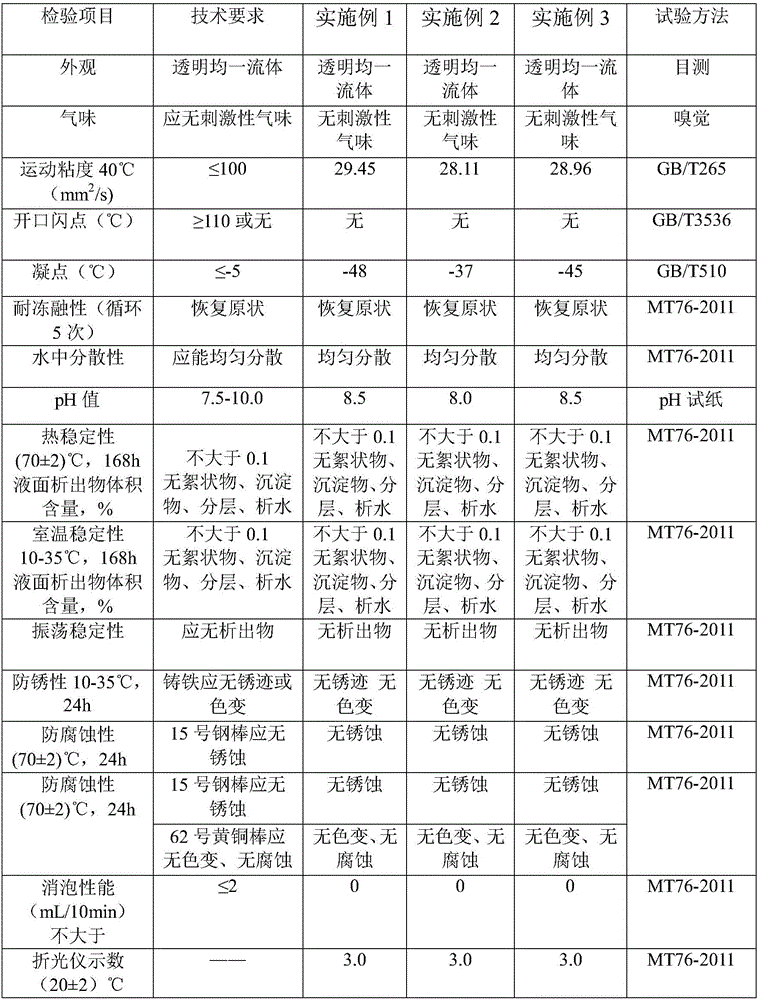

[0021] As measured by the provincial technical supervision department, the typical data and performance indicators of the concentrate for the novel environment-friendly flame retardant hydraulic support prepared in Examples 1-3 of the present invention are shown in Table 1.

[0022] Table 1 Typical data and performance indicators of the concentrate used for the new environmentally friendly and flame-retardant h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com