Mini-emulsion used for thickened oil recovery and preparation method thereof

An emulsion, small technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of solvent volatile flash point, affecting application effect, safety hazards and other problems, achieving good reproducibility and no flash point, the effect of good viscosity reduction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1 A kind of fine emulsion that is used for heavy oil recovery

[0030] Including the following components and parts by weight: 60 parts of organic solvents, 8 parts of nonionic surfactants, 8 parts of anionic oligomeric surfactants and 124 parts of deionized water;

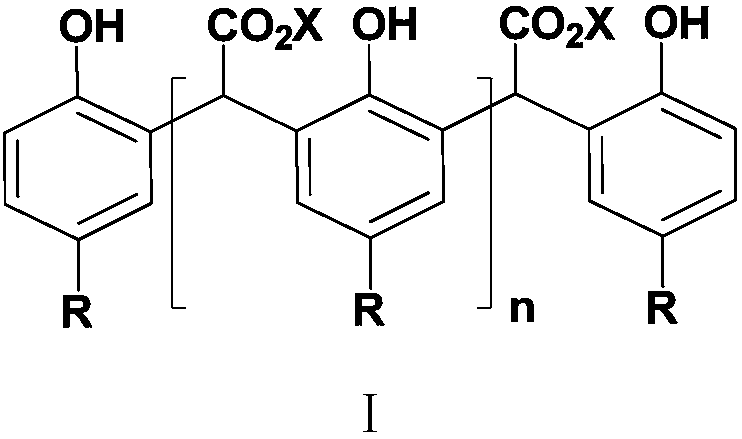

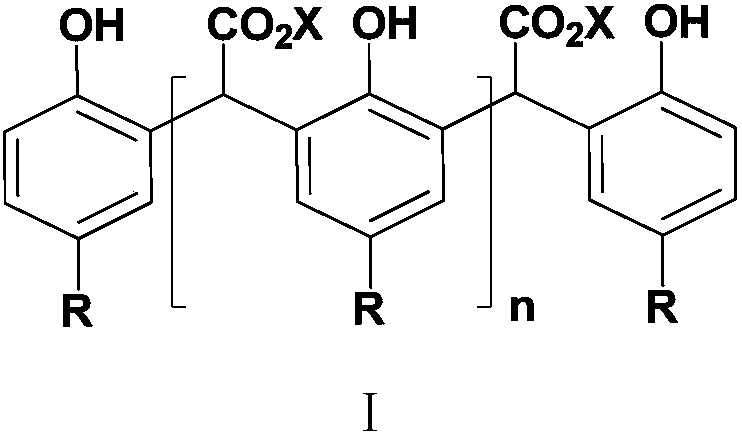

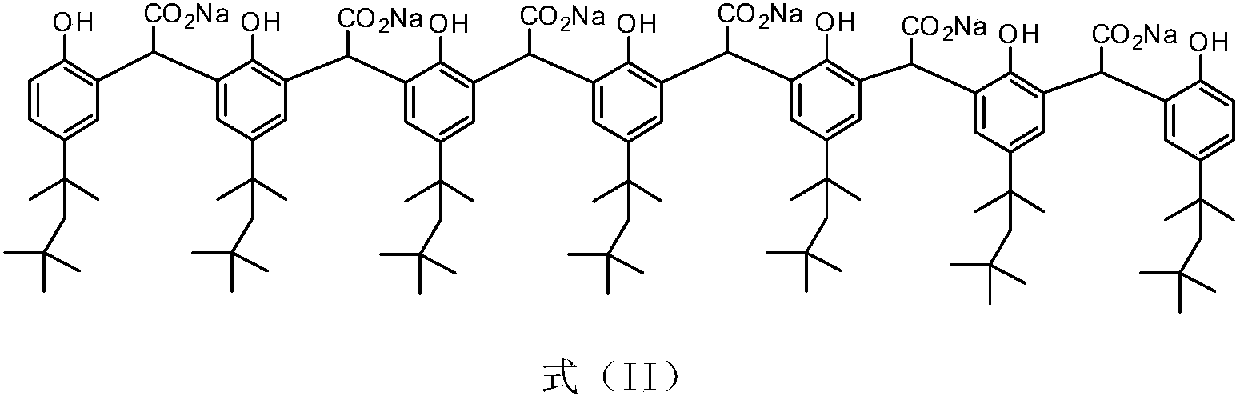

[0031] Organic solvent is toluene; Nonionic surfactant is polyoxyethylene fatty alcohol ether (Brij30); Anionic oligomeric surfactant is structural formula as shown in formula (II):

[0032]

[0033] The preparation method is:

[0034] (1) Add the nonionic surfactant and the anionic oligomeric surfactant into the organic solvent, and after stirring for 10 minutes, the system is uniformly dispersed to obtain a solvent precursor;

[0035] (2) Add deionized water dropwise to the solvent precursor prepared in step (1), and the dropping time is 50 minutes;

[0036] (3) After adding the deionized water dropwise, continue to stir for 25 minutes to obtain.

Embodiment 2

[0040] Example 2 A kind of fine emulsion used for heavy oil recovery

[0041] Including the following components and their parts by weight: 40 parts of organic solvents, 6 parts of nonionic surfactants, 4 parts of anionic oligomeric surfactants and 150 parts of deionized water;

[0042] Organic solvent is gasoline; Nonionic surfactant is polyoxyethylene polyol fatty acid ester (Tween80); Anionic oligomeric surfactant is structural formula as shown in formula (Ⅲ):

[0043]

[0044] The preparation method is:

[0045] (1) Add the nonionic surfactant and the anionic oligomeric surfactant into the organic solvent, and after stirring for 20 minutes, the system is uniformly dispersed to obtain a solvent precursor;

[0046] (2) Add deionized water dropwise to the solvent precursor prepared in step (1), and the dropping time is 40 minutes;

[0047] (3) After adding the deionized water dropwise, continue to stir for 60 minutes to obtain.

Embodiment 3

[0051] Embodiment 3 A kind of fine emulsion that is used for heavy oil recovery

[0052] Including the following components and parts by weight: 60 parts of organic solvent, 20 parts of anionic oligomeric surfactant and 120 parts of deionized water;

[0053] Organic solvent is n-octane; Anionic oligomeric surfactant is identical with embodiment 2;

[0054] The preparation method is:

[0055] (1) Add the anionic oligomeric surfactant into the organic solvent, and after stirring for 25 minutes, the system is uniformly dispersed to obtain a solvent precursor;

[0056] (2) Add deionized water dropwise to the solvent precursor prepared in step (1), and the dropping time is 40 minutes;

[0057] (3) After adding the deionized water dropwise, continue to stir for 40 minutes to obtain.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com