Oil stain cleaning agent

A technology of oil stain cleaning agent and cleaning agent, which is applied in the direction of detergent compounding agent, detergent composition, washing composition bleaching agent, etc., can solve the problems of high cost, insufficient cleaning power, poor environmental protection performance, etc., and achieve strong environmental protection performance , no flash point, low ozone destruction coefficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

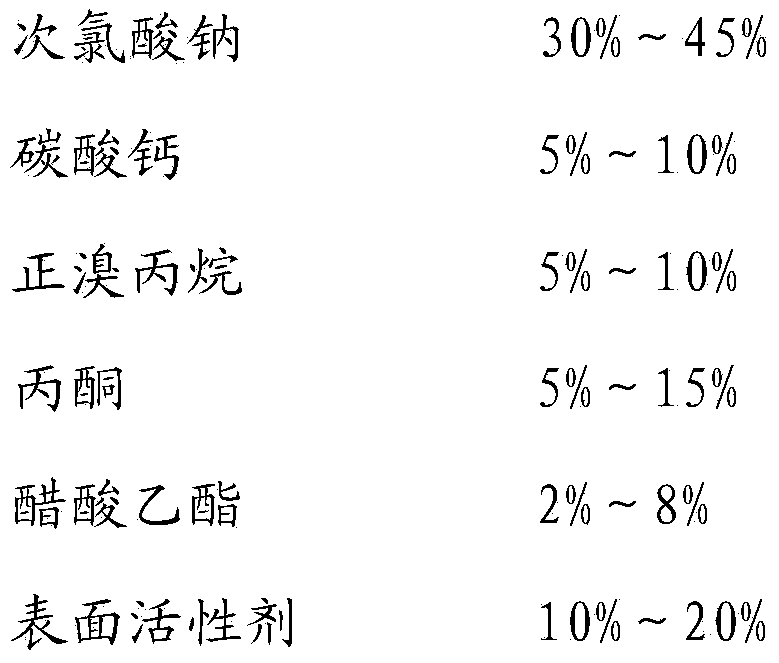

[0019] A kind of greasy dirt cleaning agent, the weight proportion of each component of this cleaning agent is:

[0020]

[0021]

[0022] The balance is deionized water.

[0023] The above-mentioned sodium hypochlorite is an industrial or medical liquid product, the molecular formula of calcium sodium hypochlorite is Naclo, its available chlorine content: >85 g / liter, sodium hydroxide <10%. Preferably, the surfactant is an amphoteric surfactant and / or a tannin surfactant, and the amphoteric surfactant is betaine and / or imidazoline.

[0024] The manufacturing process of the cleaning agent of the present invention is very simple. According to the weight ratio of each component, pour each component into a reaction kettle or a container at room temperature, and mix them evenly to become the finished product of the special cleaning agent for stone materials.

Embodiment 2

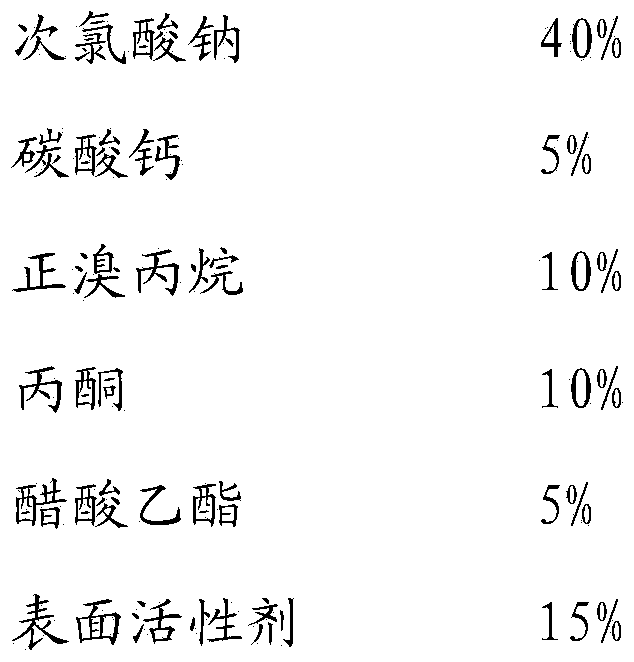

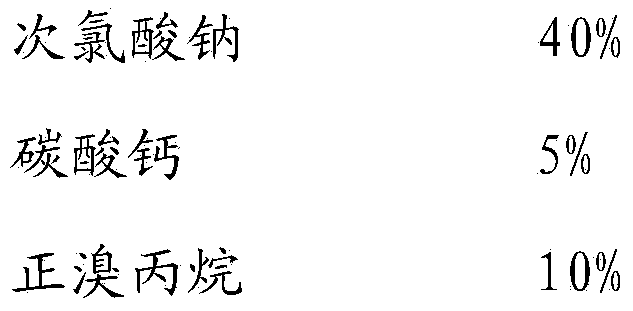

[0026] A kind of greasy dirt cleaning agent, the weight proportion of each component of this cleaning agent is:

[0027]

[0028] The balance is deionized water.

[0029] When cleaning the stone, you can also add plasma water to dilute it according to the texture and external conditions of the stone itself. After cleaning, rinse it with clean water to get the ideal cleaning effect.

[0030] The cleaning agent has added sodium hypochlorite with decontamination and bleaching functions, n-bromopropane, calcium carbonate, acetone, ethyl acetate, surfactants, etc. with decontamination, oil penetration and lubrication functions, which enhance the interaction between dirt and chlorine atoms. Combined, it can effectively clean the water stains and oil stains of silicate products, and the cleaning effect is very good; at the same time, the cleaning agent of the present invention has strong decontamination ability, low cost, and is a liquid preparation, which is simple and convenient...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com