Method of simultaneously preparing perfluoroamyl ether and perfluoroisobutyl ether

A technology of perfluoroisobutyl ether and perfluoropentyl ether, applied in the field of simultaneous preparation of perfluoropentyl ether and perfluoroisobutyl ether, which can solve the problems of separation and purification, many by-products, and large power consumption , to achieve the effect of mild conditions, simple operation and high conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

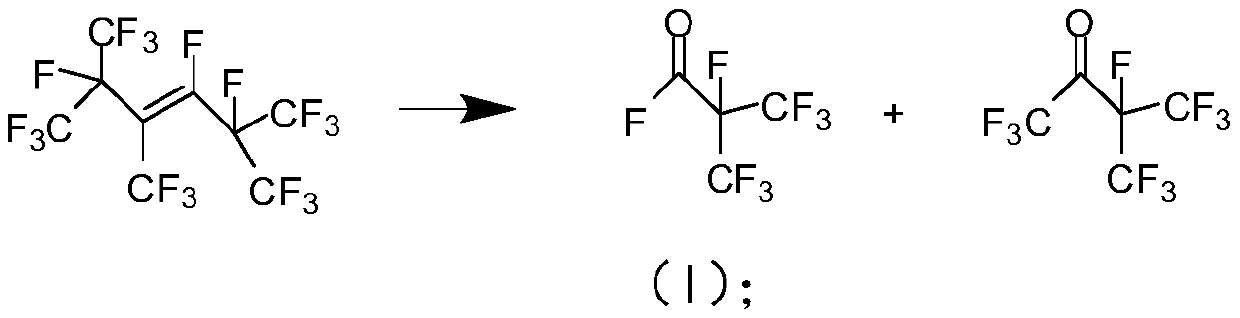

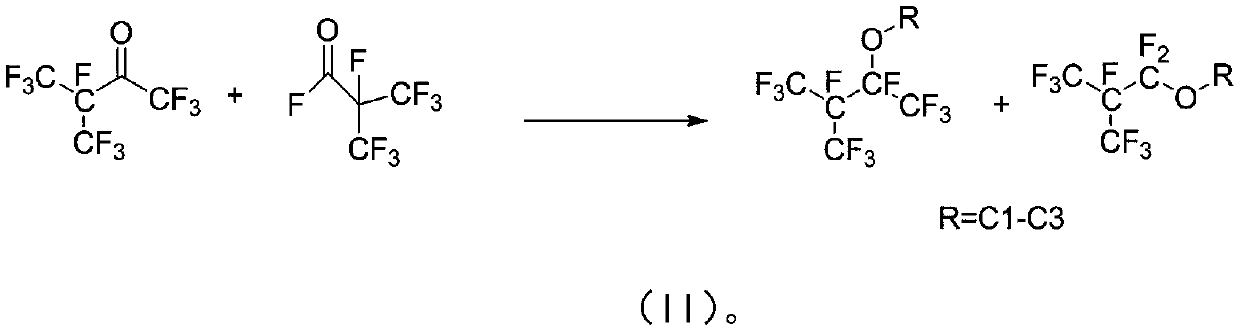

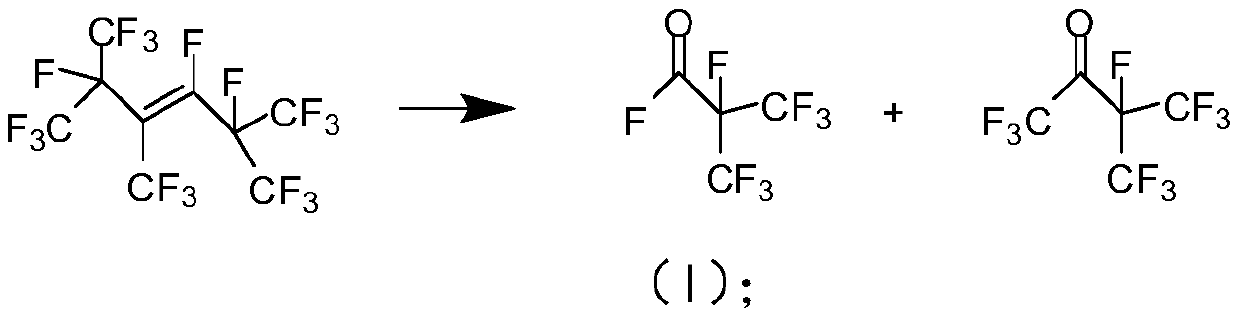

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: the preparation of hexafluoropropylene trimer raw material: hexafluoropropylene gas is passed through the catalytic reaction tube that NaF / Al2O3 catalyst is housed, and the loading capacity of catalyst is 10%, and the temperature of catalyst catalytic reaction tube is 260 ℃, contacts The time is 0.1s; the reacted mixed gas enters the condenser with a cooling jacket from the air inlet, the temperature of the condensed water is 10°C, and the unreacted hexafluoropropylene is circulated to the catalytic reaction tube of the catalyst through the outlet. The purity of the liquid hexafluoropropylene trimer in the condenser was detected to be 99.3%. The yield of hexafluoropropylene trimer is shown in Table 1.

Embodiment 2

[0031]Example 2: Preparation of raw materials for hexafluoropropylene trimer: pass hexafluoropropylene gas through a catalytic reaction tube equipped with an AgF / C catalyst, the loading of the catalyst is 15%, the temperature of the catalytic reaction tube of the catalyst is 300 ° C, contact The time is 10s; the reacted mixed gas enters the condenser with a cooling jacket from the air inlet, the temperature of the condensed water is 10°C, and the unreacted hexafluoropropylene is circulated to the catalytic reaction tube of the catalyst through the outlet. The purity of the liquid hexafluoropropylene trimer in the condenser was detected to be 99.3%. The productive rate of hexafluoropropylene trimer after applying mechanically is shown in Table 1.

Embodiment 3

[0032] Example 3: Preparation of hexafluoropropylene trimer raw material: Hexafluoropropylene gas is passed through a catalytic reaction tube equipped with a KF / C catalyst, the loading of the catalyst is 20%, and the temperature of the catalytic reaction tube of the catalyst is 320°C. The time is 30s; the reacted mixed gas enters the condenser with a cooling jacket through the air inlet, the temperature of the condensed water is 10°C, and the unreacted hexafluoropropylene is circulated to the catalytic reaction tube of the catalyst through the outlet. The purity of the liquid hexafluoropropylene trimer in the condenser was detected to be 99.3%. The productive rate of hexafluoropropylene trimer after applying mechanically is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com