Evaporative cooling flame retardant battery system

A battery system, evaporative cooling technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve problems such as manufacturing and maintenance difficulties, achieve simple structure, ensure temperature uniformity, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manner of the present invention will be described in detail below by describing the best embodiment of the present invention with reference to the accompanying drawings.

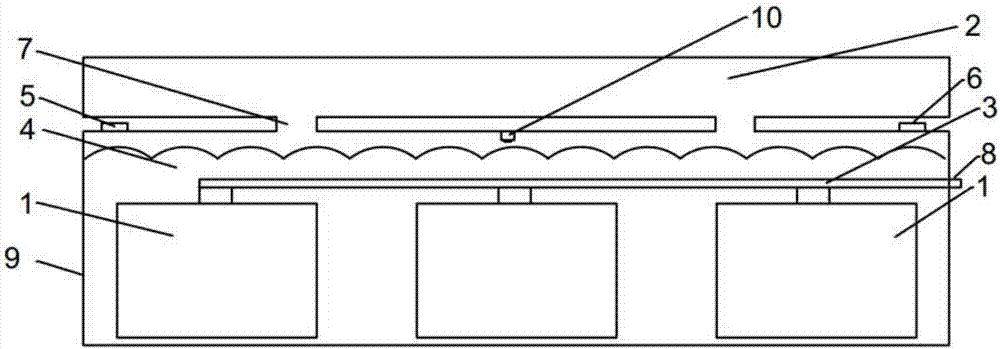

[0028] like figure 1 As shown, an evaporative cooling flame retardant battery system of the present invention includes a battery 1, a casing 9 and a coolant, and the evaporative cooling flame retardant battery system also includes a connector 3, a pressure relief valve 5, a solenoid valve 6, a cooling 2, pipeline 7, pressure sensor 10 and total positive / total negative interface 8; the battery 1 and connector 3 are connected in sequence and immersed in the cooling liquid 4; the cooling liquid 4 is a fluorocarbon compound, specifically VXF4310 .

[0029] The connector 3 is a copper bar.

[0030] The waterproof and dustproof of the box body 1 reaches the protection level of IP67.

[0031] The relief pressure of the pressure relief valve 5 is 90% of the maximum bearing press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com