Environment-friendly water-based ceramic base anticorrosion material

An anti-corrosion material, ceramic-based technology, used in anti-corrosion coatings, coatings, etc., to achieve the effect of simple process, high hardness and strong anti-corrosion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

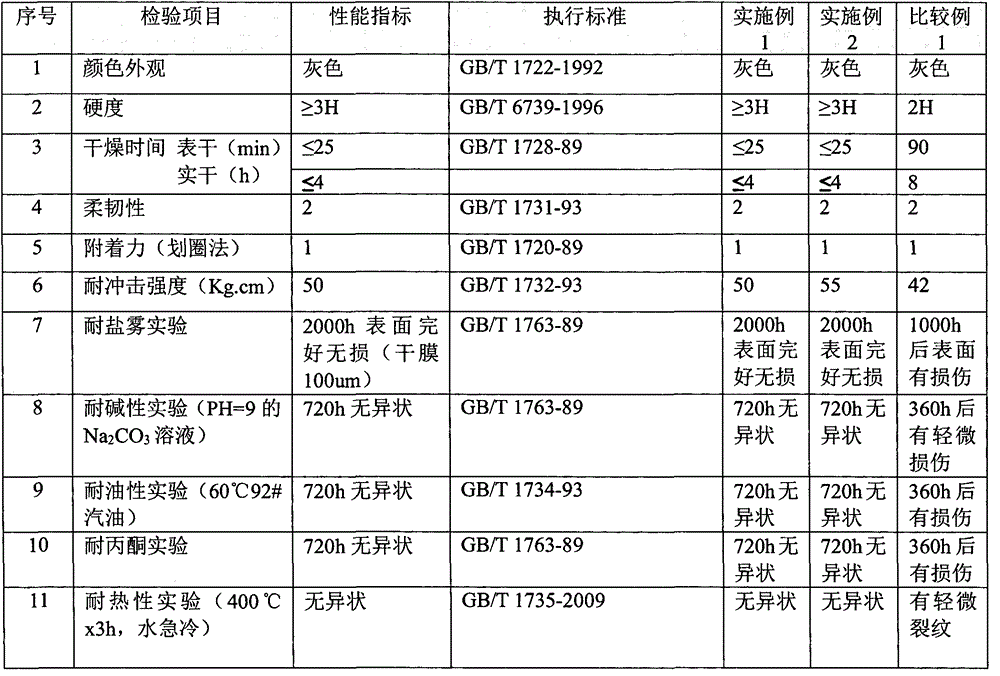

Examples

Embodiment 1

[0032] A kind of environment-friendly water-based ceramic base anticorrosion material, its component weight is Kg:

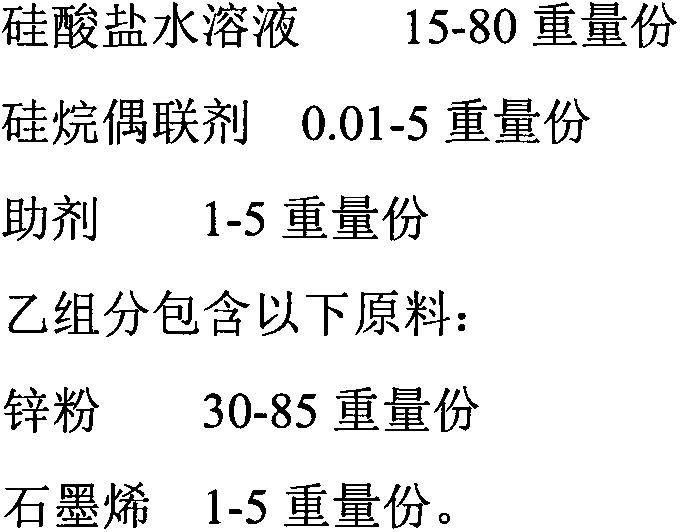

[0033] A component

[0034] 30wt% lithium silicate aqueous solution 65

[0035] Methyltrimethoxysilane 0.6

[0036] Auxiliary polyethylene glycol methyl ether 1

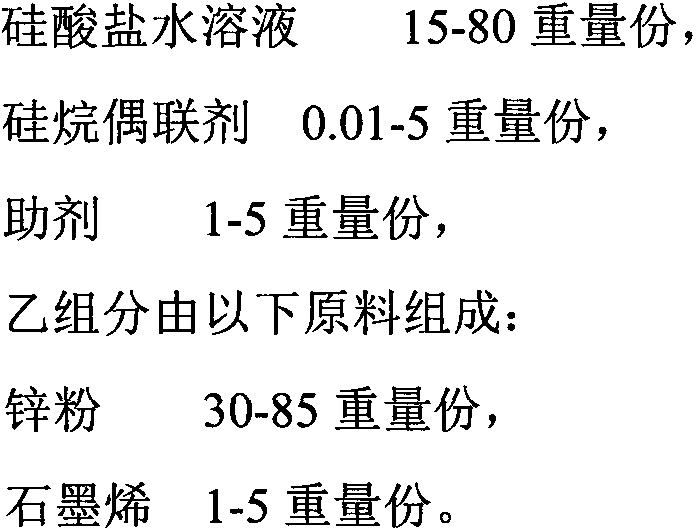

[0037] B component

[0039] Graphene 1

[0040] 1. Add 65Kg of 30wt% lithium silicate aqueous solution in component A, 0.6Kg of methyltrimethoxysilane, and 1Kg of polyethylene glycol methyl ether as an auxiliary agent, and mix them at 40°C. The reaction time is 2 Hour.

[0041] 2. After 30Kg of zinc powder in component B is filtered through a sieve, mix it with 1Kg of graphene evenly, then add it to the solution in step (1), and mix it evenly.

Embodiment 2

[0043] A kind of environment-friendly water-based ceramic base anticorrosion material, its component weight is Kg:

[0044] A component

[0045] 30wt% lithium silicate aqueous solution 65

[0046] Methyltrimethoxysilane 0.6

[0047] Auxiliary polyethylene glycol methyl ether 1

[0048] B component

[0049] Zinc powder 30

[0050] Graphene 2

[0051] 1. Add 65Kg of 30wt% lithium silicate aqueous solution in component A, 0.6Kg of methyltrimethoxysilane, and 1Kg of polyethylene glycol methyl ether as an auxiliary agent, and mix them at 40°C. The reaction time is 2 Hour.

[0052] 2. After filtering 30Kg of zinc powder in component B through a sieve, mix it with 2Kg of graphene evenly, then add it to the solution in step (1), and mix it evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com