Device for achieving flue gas power generation and removing harmful substance in flue gas simultaneously

A technology for harmful substances and flue gas, which is used in combination devices, gas treatment, vapor condensation, etc. to achieve the effect of stable chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

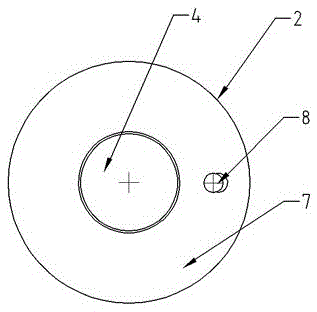

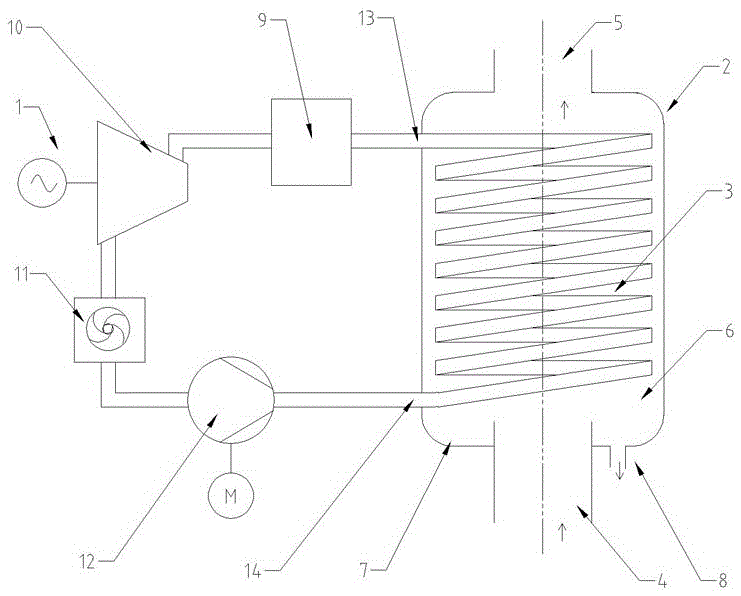

[0015] attached Figure 1-2 Represents a device for generating electricity from flue gas while removing harmful substances in flue gas, including a flue gas treatment system, an energy conversion system and a generator 1; the flue gas treatment system consists of a casing 2, a heat exchanger 3, a flue gas inlet 4, The flue gas outlet 5 is composed of; the heat exchanger 3 is placed in the shell 2 and is composed of a coil with fins on the surface; the space enclosed between the inner surface of the shell 2 and the outer surface of the heat exchanger 3 is the flue gas channel 6 The flue gas inlet 4 is below the casing 2, and the flue gas outlet 5 is above the casing 2; at the interface between the inner surface of the lower part of the casing 2 and the flue gas inlet 4, an annular condensed water collection tank 7 is formed, and the condensed water colle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| critical temperature | aaaaa | aaaaa |

| critical pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com