Composition applied to atomization film, atomization film and LED lighting equipment

A technology of composition and atomized film, which is applied in the direction of lighting and heating equipment, lighting devices, parts of lighting devices, etc., can solve the problems of not being able to achieve anti-glare, extinction spots, and not being able to cover optical defects well, Achieve the effect of reducing light loss, soft and uniform light, and reducing irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Embodiment 1: the preparation of composition 1

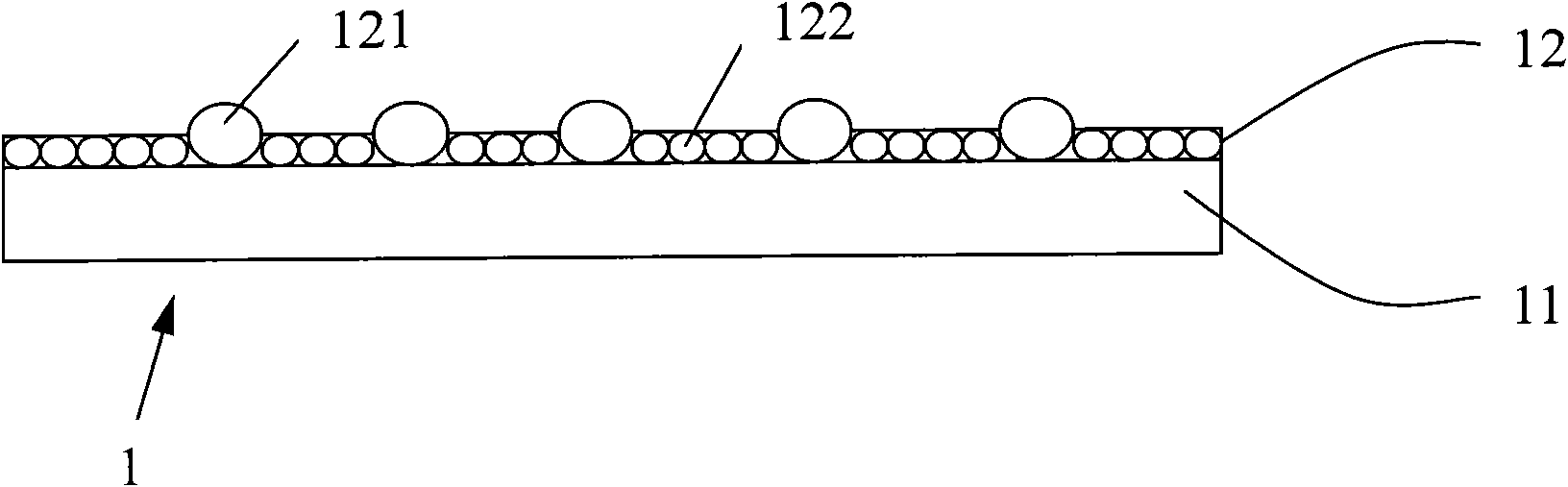

[0061] Add 6 parts by weight of solvent ethyl acetate in the container, slowly add 1 part by weight of organic particle siloxane (average particle diameter is 1 μm), after stirring evenly, add 1 part by weight of inorganic particle silica (particle diameter is 1 μm) 0.1-2μm), and then add 5.5 parts by weight of two-component polyurethane adhesive (first add 5 parts by weight of polyethylene adipate glycol main agent, and then gradually add 0.5 parts by weight of IPDI curing agent), Stir evenly to obtain composition 1 of the present invention.

Embodiment 2

[0062] Embodiment 2: the preparation of composition 2

[0063] Add 7 parts by weight of solvent butyl acetate in the container, slowly add 2 parts by weight of organic particles PS (average particle diameter is 1 μm), after stirring evenly, add 2 parts by weight of inorganic particles (including 1 part by weight of silicon dioxide and 1 part by weight of titanium dioxide, the particle size is 0.1-2 μm), and then add 6.6 parts by weight of two-component polyurethane adhesive (first add 6 parts by weight of polyethylene adipate glycol main agent, and then gradually Add 0.6 parts by weight of XDI curing agent) and stir evenly to obtain composition 2 of the present invention.

Embodiment 3

[0064] Embodiment 3: the preparation of composition 3

[0065] Add 8 parts by weight of solvent cyclohexanone in the container, slowly add 2.5 parts by weight of organic particle PMMA (average particle diameter is 2 μm), after stirring evenly, add 2.5 parts by weight of inorganic particle calcium carbonate (particle diameter is 0.1-2 μm) ), then add the two-component polyurethane adhesive of 7.7 parts by weight (first add the polyethylene adipate glycol-propylene glycol ester glycol main agent of 7 parts by weight, then gradually add the XDI curing agent of 0.7 parts by weight), stir Uniformly, the composition 3 of the present invention was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com