Transparent toughened light-diffusion polymethylmethacrylate material and preparation method for same

A technology of polymethyl methacrylate and light diffusion, which is applied in the field of polymer materials, can solve the problems of PMMA resin such as low extensibility, poor toughness, difficult to balance toughness and transparency, and achieve high transparency and expand the application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

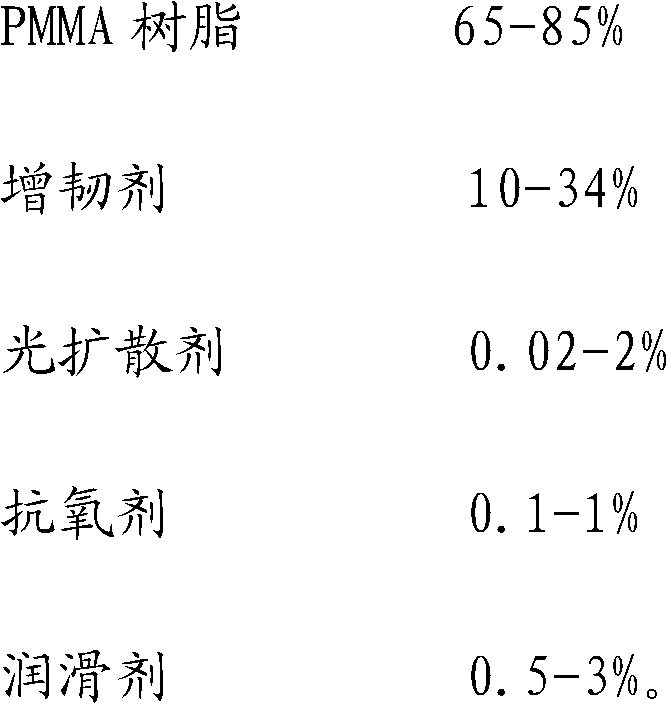

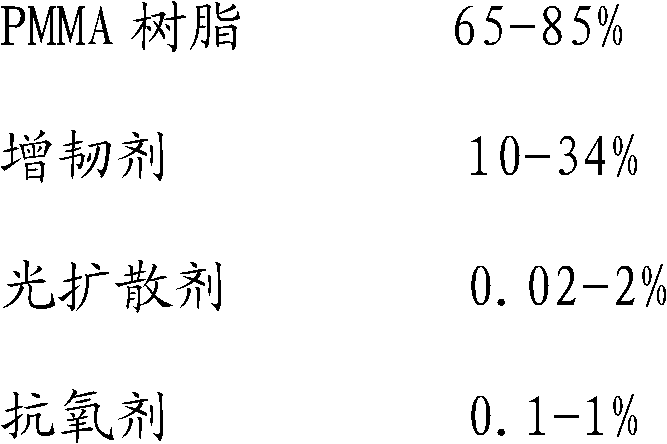

[0018] The transparent and toughened light-diffusing polymethyl methacrylate material in this embodiment is composed of the following components by weight percentage:

[0019] PMMA resin 85%, toughening agent 13.5%, light diffusing agent (MS05) 0.5%, antioxidant 0.3%, lubricant 0.7%.

[0020] Its preparation method is as follows:

[0021] Step 1, each component is weighed by the above-mentioned percentage by weight;

[0022] Step 2, each component that takes by weighing is mixed 3min in the high-speed mixer, and the high-speed mixer rotating speed is 800 rpm;

[0023] Step 3, the mixed material is placed in a twin-screw extruder, melted and reacted, extruded and granulated; the process conditions of the twin-screw extruder are:

[0024] The temperature in the first zone is 190°C, the temperature in the second zone is 200°C, the temperature in the third zone is 210°C, the temperature in the fourth zone is 200°C, the melt pressure is 8MPa, and the vacuum degree is -0.03MPa.

Embodiment 2

[0026] The transparent and toughened light-diffusing polymethyl methacrylate material in this embodiment is composed of the following components by weight percentage:

[0027] PMMA resin 75%, toughening agent 23%, light diffusing agent (MS05) 1%, antioxidant 0.3%, lubricant 0.7%.

[0028] Its preparation method is as follows:

[0029] Step 1, each component is weighed by the above-mentioned percentage by weight;

[0030] Step 2, mixing each component weighed in a high-speed mixer for 5min, and the speed of the high-speed mixer is 800 rpm;

[0031] Step 3, the mixed material is placed in a twin-screw extruder, melted and reacted, extruded and granulated; the process conditions of the twin-screw extruder are:

[0032] The temperature in the first zone is 200°C, the temperature in the second zone is 210°C, the temperature in the third zone is 220°C, the temperature in the fourth zone is 210°C, the melt pressure is 10MPa, and the vacuum degree is -0.06MPa.

Embodiment 3

[0034] The transparent and toughened light-diffusing polymethyl methacrylate material in this embodiment is composed of the following components by weight percentage:

[0035] PMMA resin 65%, toughening agent 32.5%, light diffusing agent (MS05) 1.5%, antioxidant 0.3%, lubricant 0.7%.

[0036] Its preparation method is as follows:

[0037] Step 1, each component is weighed by the above-mentioned percentage by weight;

[0038] Step 2, mixing each component weighed in a high-speed mixer for 4min, and the speed of the high-speed mixer is 800 rpm;

[0039] Step 3, the mixed material is placed in a twin-screw extruder, melted and reacted, extruded and granulated; the process conditions of the twin-screw extruder are:

[0040] The temperature in the first zone is 200°C, the temperature in the second zone is 205°C, the temperature in the third zone is 215°C, the temperature in the fourth zone is 210°C, the melt pressure is 12MPa, and the vacuum degree is -0.04MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com