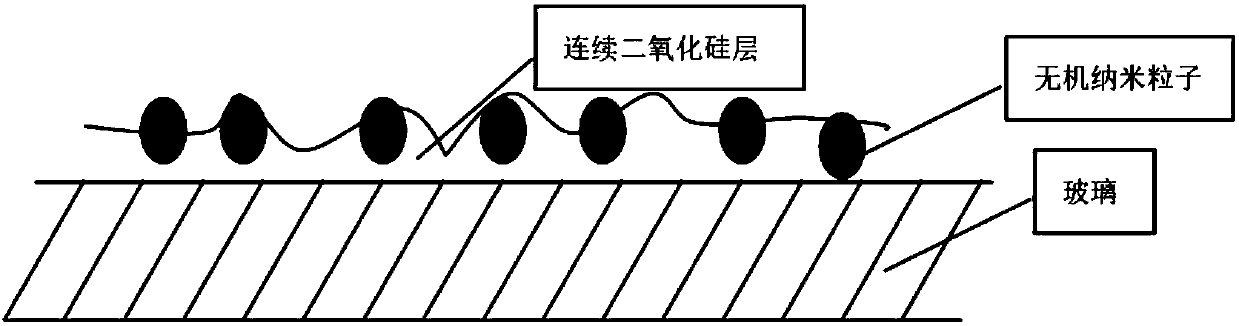

High-haze low-gloss anti-glare film and preparation method thereof

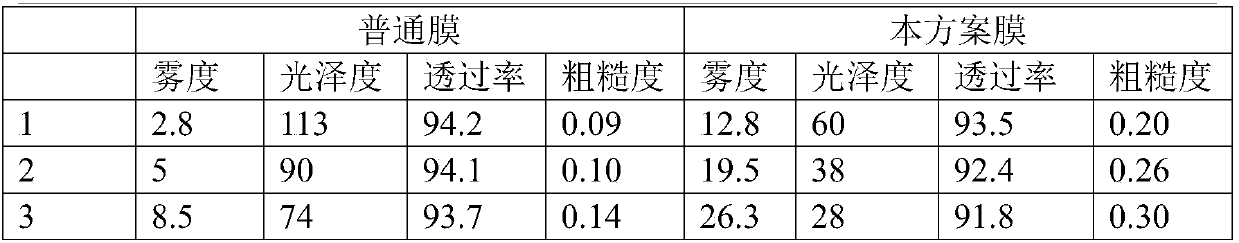

A low-gloss, anti-glare film technology, applied in coatings and other directions, can solve the problems of low-gloss anti-glare film, glass coating haze and insufficient gloss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This embodiment provides a method for constructing a high-haze and low-gloss anti-glare film, including the preparation of a specific anti-glare chemical solution and the wet spraying film-forming process.

[0048] The molar ratio of raw materials tetraethyl orthosilicate, pure water, hydrochloric acid, and ethanol is 1:2.5:0.06:6, in which ethyl orthosilicate and ethanol are premixed, and hydrochloric acid and pure water are premixed. Afterwards, the above two components were gradually mixed and stirred evenly, and the whole stirring reaction lasted for 4 hours, and finally the basic anti-glare medicinal solution was prepared.

[0049] The silane coupling agent KH-550 was selected as the surface modifier of the inorganic nanoparticles and pre-hydrolyzed. Nano zirconia with a size of 300-700nm is added to the above hydrolyzate, and refluxed at 60° C. for 1 hour to complete the silanization of the surface of the nano zirconia particles.

[0050] Add nano-zirconia silani...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com