Blue-ray-proof lens and resin raw material thereof

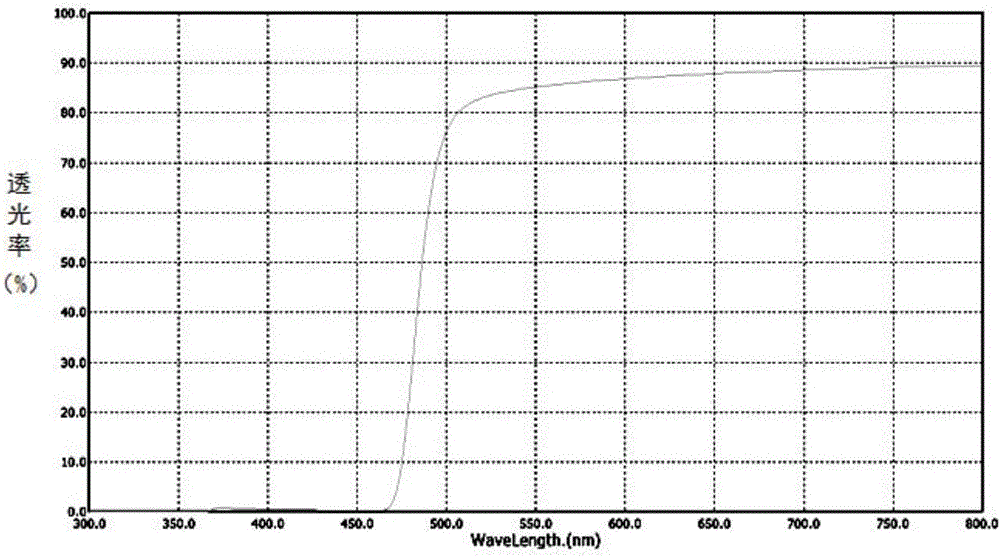

An anti-blue light and lens technology, applied in the lens field, can solve the problems of damage to the wearer's eyesight, complex process, high cost, etc., and achieve the effects of high and low haze, high light transmittance, and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] As an improvement of the anti-blue light lens of the present application, the method of surface modification treatment adopts in-situ polymerization modification method to overcome the defect that nanomaterials are extremely prone to agglomeration. The preparation method includes at least the following steps:

[0032] (1) Add the rare earth oxide and 3-methacryloyloxytrimethoxysilane (MPTMS) into the organic solvent and mix thoroughly;

[0033] (2) Then add methyl methacrylate (MMA) and initiator, mix well and react at 70-80°C for 2-8 hours;

[0034] (3) After the reaction is completed, the surface-modified nano-rare earth oxide is obtained after precipitation and drying, and the particle size of the nano-rare earth oxide after treatment is 3-10 nm.

[0035] As an improvement to the anti-blue light lens of the present application, in step (1), the mass ratio of rare earth oxide to 3-methacryloxytrimethoxysilane is 10-30:1, preferably 12.5-25: 1. Within this range, the...

Embodiment 1

[0048] 1. Add rare earth oxides and 3-methacryloxytrimethoxysilane (MPTMS) with a median particle size of 2 to 5 nm into toluene, and the rare earth oxides are cerium oxide and praseodymium oxide with a mass ratio of 7:3 ; Mix in an ultrasonic mixer for 60 minutes to prepare an emulsion of nano-alkene earth oxides; the volume-to-weight ratio of toluene to rare earth oxides is 10:1; the ultrasonic frequency of the ultrasonic mixer is 20KHz to 40KHz;

[0049] 2. Then add methyl methacrylate and benzoyl peroxide (BPO), the mass ratio of MMA to BPO is 100:0.1; mix with an ultrasonic mixer for 20 minutes, and react at a temperature range of 75-78°C for 3-4 hours ;

[0050] 3. After the reaction is completed, add methanol to the reaction system for precipitation to obtain a light yellow precipitate. The volume ratio of methanol to toluene is 1:5-10; dry the precipitate at 80-100°C for 4-6 hours, Instant anti-blue light additive;

[0051] 4. Dry the polymethyl methacrylate resin, t...

Embodiment 2

[0056] 1. Add rare earth oxides and 3-methacryloyloxytrimethoxysilane (MPTMS) into toluene, and mix them in an ultrasonic mixer for 60 minutes to obtain an emulsion of nano-alkene earth oxides; the mixture of toluene and rare earth oxides The volume-to-weight ratio is 10:1; the mass ratio of rare earth oxide to MPTM is 20:1; the ultrasonic frequency of the ultrasonic mixer is 20KHz-40KHz;

[0057] 2. Then add methyl methacrylate and benzoyl peroxide (BPO), the weight ratio of MMA to BPO is 100:0.1; use an ultrasonic mixer to mix for 20 minutes, and react at a temperature range of 75-78°C for 3-4 Hour; Wherein, the mass ratio of MPTMS and MMA is 1:80;

[0058] 3. After the reaction is completed, add methanol to the reaction system for precipitation to obtain a light yellow precipitate, the volume ratio of methanol to toluene is 1:5-10; dry the precipitate at 80-100°C for 4-6 hours, that is Anti-blue light additive;

[0059] 4. Dry the polymethyl methacrylate resin, then add a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com