A modified aligned carbon nanotube bundle and its preparation method

A technology for the modification of oriented carbon nanotubes, applied in textiles, papermaking, fiber treatment, etc., can solve the problems of complex process, easy damage of tube wall, easy generation of defects in carbon tube structure, etc., and achieve simple coating technology , Improve the interface effect and protect the effect of the orientation structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

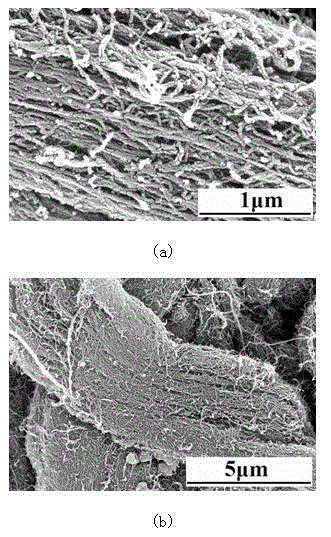

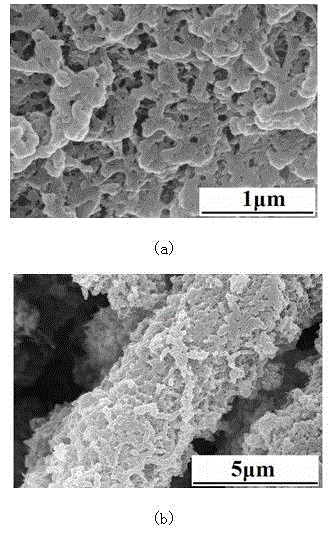

[0019] In a container equipped with a stirrer, weigh 5g of urea and 10g of formaldehyde solution (mass concentration 37-40%). After the urea is fully dissolved, heat slowly and use lye to adjust the pH value of the solution to 8-9. Insulate at 50-70°C for 0.5-1h to obtain a urea-formaldehyde prepolymer solution, then add 50g of deionized water and 1g of aligned carbon nanotube bundles, after ultrasonic dispersion and mechanical stirring, set a certain stirring speed (500rpm), use acid The pH value of the solution is adjusted to 2-4, and the temperature is raised slowly. When the temperature rises to 45-50° C., the temperature is kept for 3-4 hours, and the reaction is terminated. The product is washed several times with water, filtered and dried to obtain a polyurea-formaldehyde polymer-coated aligned carbon nanotube bundle product. See attached figure 1 , which is an SEM image of aligned carbon nanotube bundles; see attached figure 2 , which is the SEM photo of the polyure...

Embodiment 2

[0021] In a container equipped with a stirrer, weigh 30g of urea and 60g of formaldehyde solution (mass concentration 37-40%). After the urea is fully dissolved, heat slowly and adjust the pH value of the solution to 8-9 with lye. Keep warm at 50-70°C for 0.5-1h to obtain urea-formaldehyde prepolymer solution, then add 30g sodium lauryl sulfate, 3000g deionized water and 50g aligned carbon nanotube bundles, after ultrasonic dispersion and mechanical stirring, set a certain Stirring speed (10000rpm), adjust the pH value of the solution to 2-4 with acid solution, slowly raise the temperature, wait for the temperature to rise to 45-50°C, keep it warm for 3-4h, and end the reaction. The product is washed several times with water, filtered and dried to obtain polyurea-formaldehyde polymer-coated carbon tube bundle product. See attached image 3 , is the SEM photo of the polyurea-formaldehyde polymer-coated aligned carbon nanotube bundle provided in this example. Compared figure ...

Embodiment 3

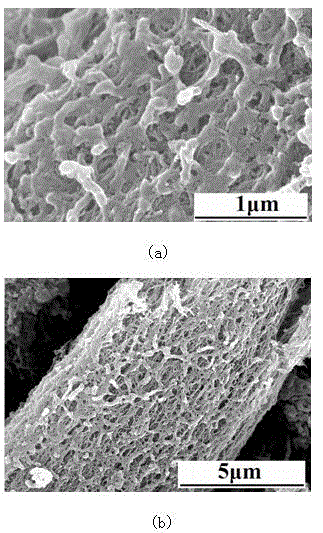

[0023] In a container equipped with a stirrer, weigh 10g of melamine and 20g of formaldehyde solution (mass concentration 37-40%). After the melamine is fully dissolved, heat slowly and use lye to adjust the pH value of the solution to 8-9. Incubate at 50-70°C for 0.5-1h to obtain a melamine-formaldehyde prepolymer solution, then add 0.5g sodium dodecylsulfonate, 500g deionized water and 10g aligned carbon nanotube bundles, ultrasonically disperse and mechanically stir, Set a certain stirring speed (900rpm), adjust the pH value of the solution to 2-4 with acid solution, slowly raise the temperature, wait until the temperature rises to 45-50°C, keep it warm for 3-4h, and end the reaction. The product is washed several times with water, filtered and dried to obtain a melamine-formaldehyde polymer-coated aligned carbon nanotube bundle product. See attached Figure 4 , is the SEM photo of the melamine-formaldehyde polymer-coated aligned carbon nanotube bundle provided in this exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com