A kind of modified high nickel material and preparation method thereof

A high-nickel, modified technology, applied in secondary battery repair/maintenance, structural parts, electrical components, etc., can solve the problems of poor material storage performance, enhanced material air sensitivity, and simultaneous recovery of lithium residues without deep removal. , to achieve stable chemical properties, good cycle stability and safety performance, and reduce air sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

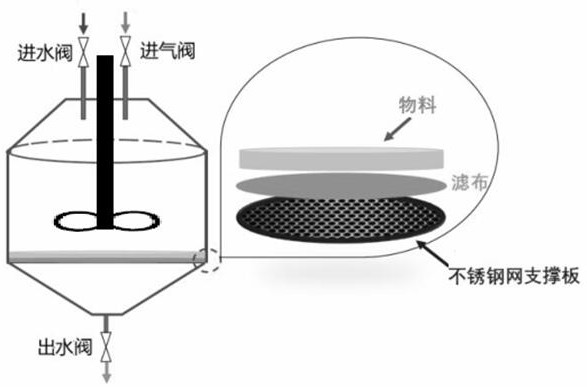

[0035] The filter press tank used in the embodiment of the present invention is as figure 1 As shown, the top of the filter press tank is provided with a water inlet and an air inlet, and the water inlet and the air inlet are respectively provided with a water inlet valve and an air inlet valve. The inside of the filter press tank is equipped with a stirring device, a stainless steel mesh support plate, and a filter cloth. A filter cloth is provided on the stainless steel mesh support plate, and the stainless steel mesh support plate divides the interior of the filter press tank into upper and lower parts. A water outlet is provided at the bottom of the lower part of the filter press tank, and a water outlet valve is arranged at the water outlet.

Embodiment 2

[0037] A preparation method of a modified high-nickel material, comprising the following steps:

[0038] (1) The high-nickel material precursor is prepared by the lithium sintering process: the high-nickel material precursor Ni 0.6 co 0.30 al 0.10 (OH) 2 Put it in a ball mill with lithium hydroxide at a molar ratio of 1:1.03 for material mixing, place the uniformly mixed material in a sintering furnace, and sinter at 550°C for 4 hours under an oxygen atmosphere, then heat up to 750°C for 10 hours. Obtain high nickel material Li 1.03 Ni 0.6 co 0.30 al 0.10 o 2 ;

[0039] (2) The high nickel material Li 1.03 Ni 0.6 co 0.30 al 0.10 o 2 The national standard method GB / T 11064.1-1989 is used to determine the lithium residue content of the material;

[0040] (3) The high nickel material Li 1.03 Ni 0.6 co 0.30 al 0.10 o 2 The material is evenly placed on the filter cloth in the sealed high-efficiency washing filter press tank in Example 1 and reinforced and sealed,...

Embodiment 3

[0047] A preparation method of a modified high-nickel material, comprising the following steps:

[0048] (1) The high-nickel material precursor is prepared by the lithium sintering process: the high-nickel material precursor Ni 0.995 al 0.005 (OH) 2 and lithium hydroxide in a ball mill at a molar ratio of 1: 1.05 for material mixing, place the uniformly mixed material in an oxygen atmosphere in a sintering furnace, sinter at 550°C for 4 hours, and then heat up to 750°C for 10 hours to obtain High nickel material Li 1.05 Ni 0.995 al 0.005 o 2 ;

[0049] (2) The high nickel material Li 1.05 Ni 0.995 al 0.005 o 2 The national standard method GB / T 11064.1-1989 is used to determine the lithium residue content of the material;

[0050] (3) The high nickel material Li 1.05 Ni 0.995 al 0.005 o 2 The material is evenly placed on the filter cloth in the sealed high-efficiency washing filter press tank in Example 1 and reinforced and sealed, and ammonium fluoride is dissol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com