Hard coating film, antireflective hard coating film, optical element and image display device

一种光学元件、防反射的技术,应用在光学元件、抗反射涂层、光学等方向,能够解决难以达到硬度卷边的平衡等问题,达到抑制裂开或卷边、高硬度、降低干涉条纹的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

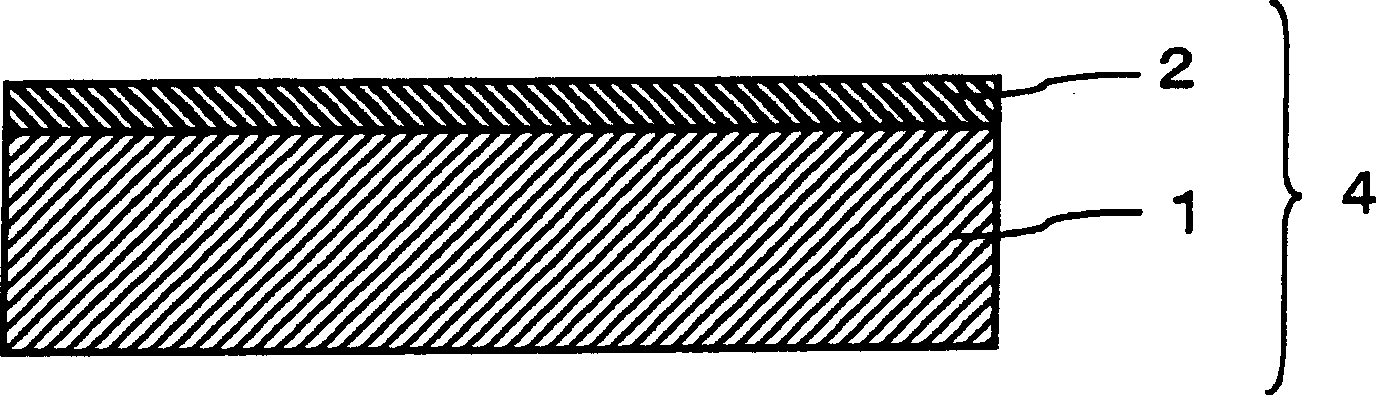

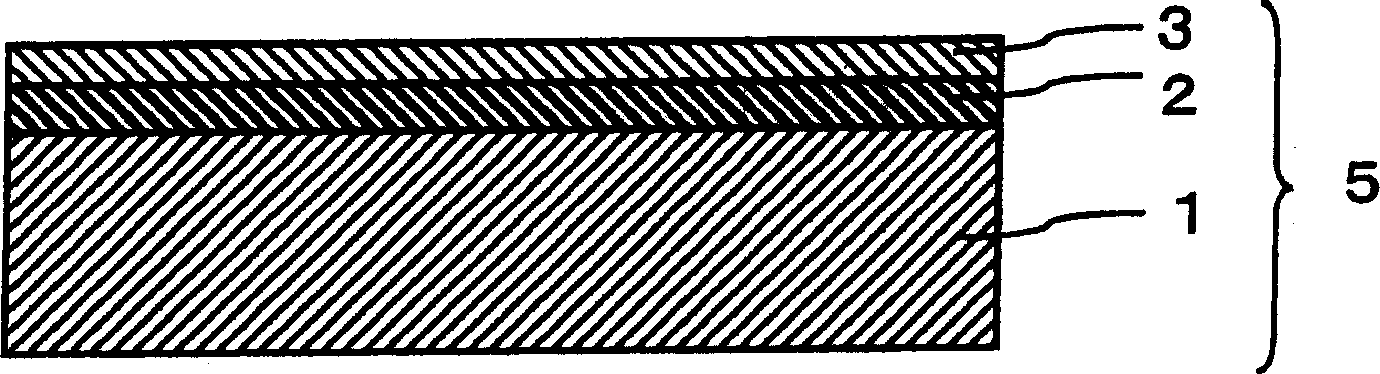

[0143] (transparent plastic film substrate)

[0144] A triacetylcellulose film (refractive index: 1.48) with a thickness of 80 μm was used.

[0145] (hard coat forming material)

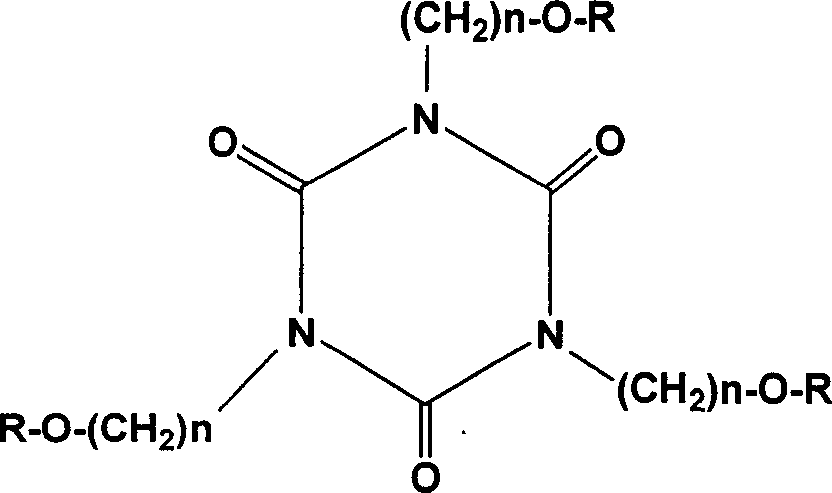

[0146] A hard coat forming material (solution) was prepared by diluting the following composition with a mixed solvent of butyl acetate and methyl ethyl ketone (1 / 2: weight ratio) so that the solid content concentration was 45%, Among them, the diluted substances are: 100 parts of urethane acrylate obtained from pentaerythritol-based acrylate and hydrogenated xylene diisocyanate as urethane acrylate (A); 20 parts of cyanic acid-tris[2(acryloyloxy)ethyl]; the average particle diameter of the inorganic ultrafine particles (C) is 10-20nm ultrafine silicon oxide and 40% relative to the total solid content; polymerization initiation The content of the solvent (Irgacure 184, manufactured by Chiba Specialty Chemicals) was 3% based on the total solid content.

[0147] (Manufacture of hard coat film)

[0...

Embodiment 2

[0150] (hard coat forming material)

[0151] In Example 1, when preparing the hard coat forming material, the usage-amount of isocyanuric acid acrylate (B) was changed to 10 parts, and further 8 parts by weight of pentaerythritol tetraacrylate were added, in addition, In the same manner as in Example 1, a hard coat layer forming material was prepared.

[0152] (Manufacture of hard coat film)

[0153] In Example 1, except having used the above-mentioned hard-coat layer formation material, and having changed the thickness of a hard-coat layer into 18 micrometers, it carried out similarly to Example 1, and obtained the hard-coat film.

Embodiment 3

[0155] (transparent plastic film substrate)

[0156] A 75 μm thick triacetylcellulose film (refractive index: 1.65) was used.

[0157] (hard coat forming material)

[0158] In Example 1, when preparing the hard coat forming material, adding ultrafine particles of titanium oxide with an average particle diameter of 10 to 20 nm as inorganic ultrafine particles (C) to make it 36% relative to the total resin component, in addition, In the same manner as in Example 1, a hard coat layer forming material was prepared.

[0159] (Manufacture of hard coat film)

[0160] In Example 1, a hard coat film was obtained in the same manner as in Example 1 except that the above-mentioned transparent plastic film substrate and hard coat layer forming material were used, and the thickness of the hard coat layer was changed to 21 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com