Underwater imaging laser lighting light spot homogenization adjusting device

A laser lighting and adjustment device technology, applied in optics, optical components, instruments, etc., can solve the problems of affecting the imaging effect of underwater cameras, uneven energy distribution, and inability to use directly, achieving good adjustment stability and convenient operation , reduce interference fringes, and reduce speckle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

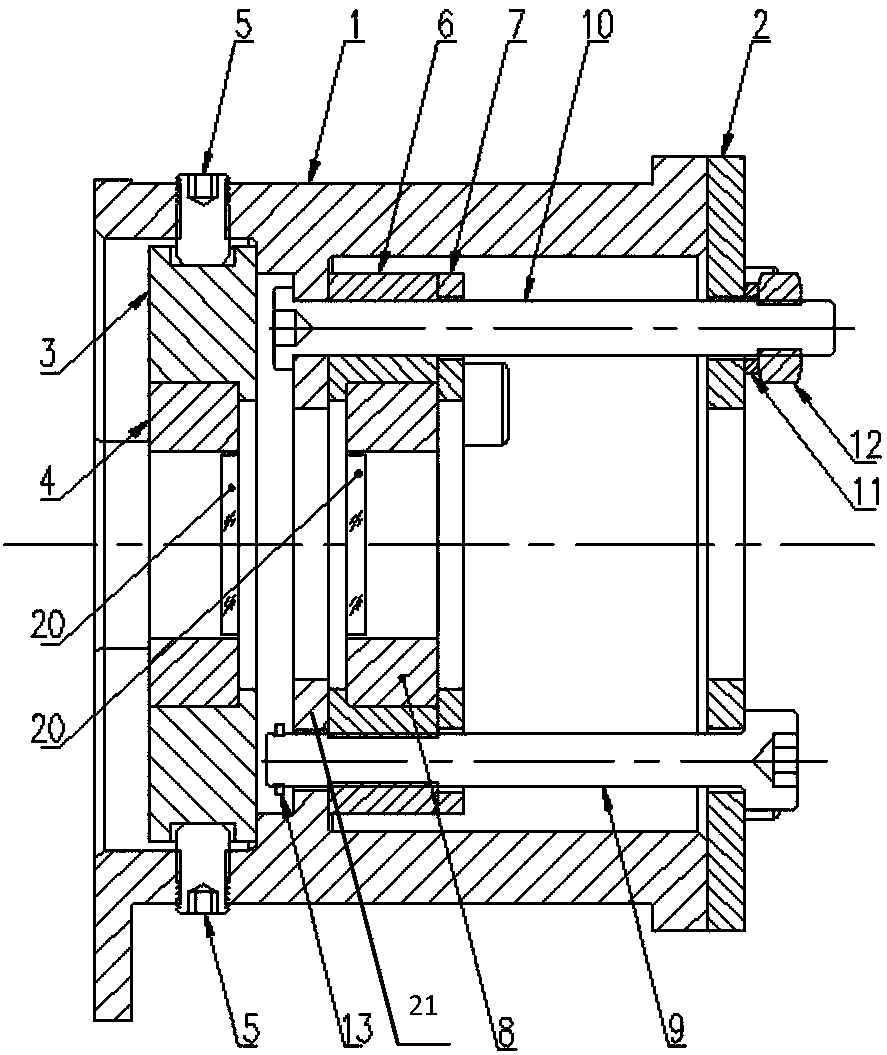

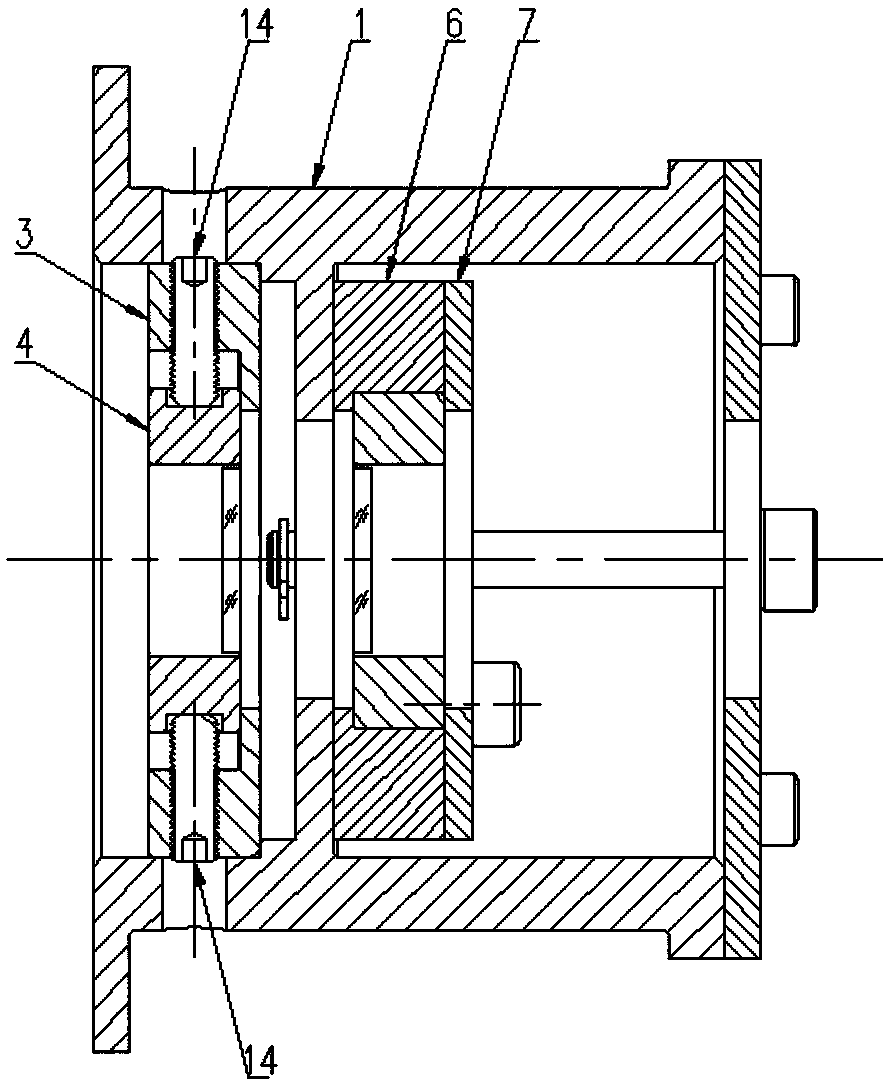

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

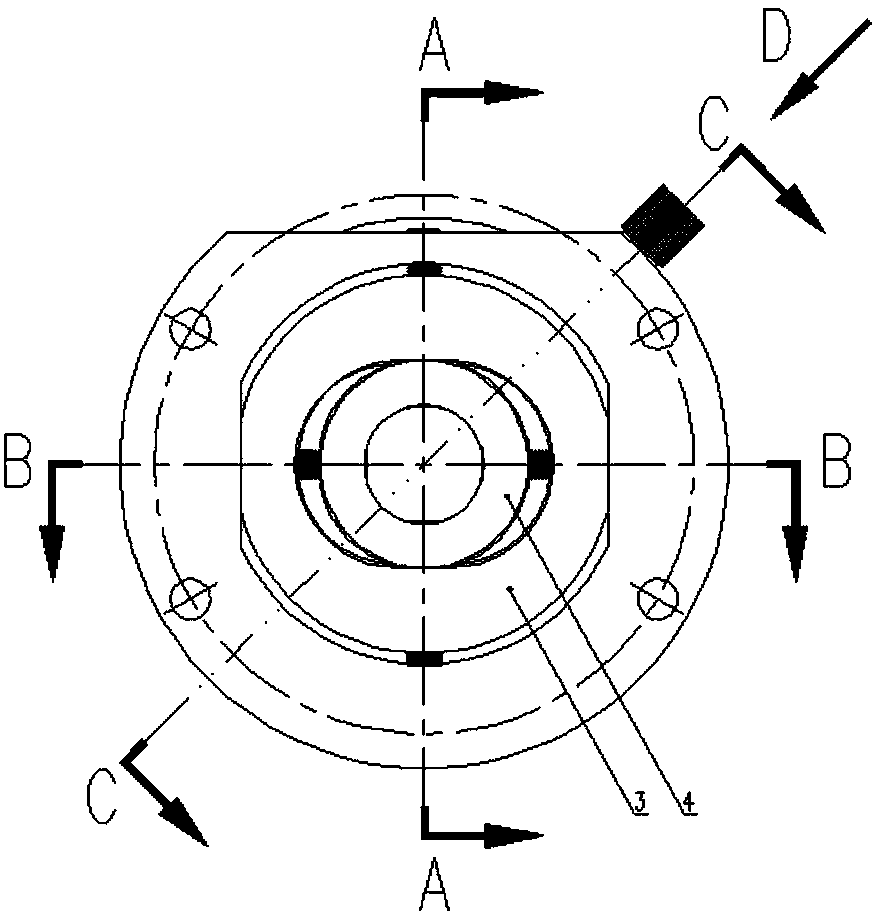

[0037] combine figure 1 and figure 2 , it can be seen that the adjustment device of the present invention mainly includes a lens barrel 1, a first fixed block 3 arranged in the lens barrel 1 and coaxial with the lens barrel 1, a second fixed block 6, a first ring 4 and a second ring Ring 8;

[0038] From figure 1 It can be seen that the inner wall of the lens barrel 1 is provided with holes, the outer wall on the left side of the first fixed block 3 is flat with the outer wall on the right side, and fits with the hole plane in the lens barrel 1, and the distance between the upper and lower arc surfaces of the hole groove is greater than that of the first fixed block 3. The distance between the upper and lower arc surfaces in the fixed block 3;

[0039] The center of the first fixed block 3 has an elliptical through hole, and the elliptical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com