Measuring device and measuring method for stitching interference of planar sub-aperture

A technology of sub-aperture splicing and sub-aperture, applied in measurement devices, optical devices, instruments, etc., can solve the problems of coma aberration of detection results, measurement errors, affecting the measurement accuracy of a single sub-aperture, and reduce the deviation between the actual position and the ideal position. , Improve the measurement accuracy and realize the effect of automatic measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to better understand the purpose, technical solutions and advantages of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the protection scope of the present invention should not be limited thereby.

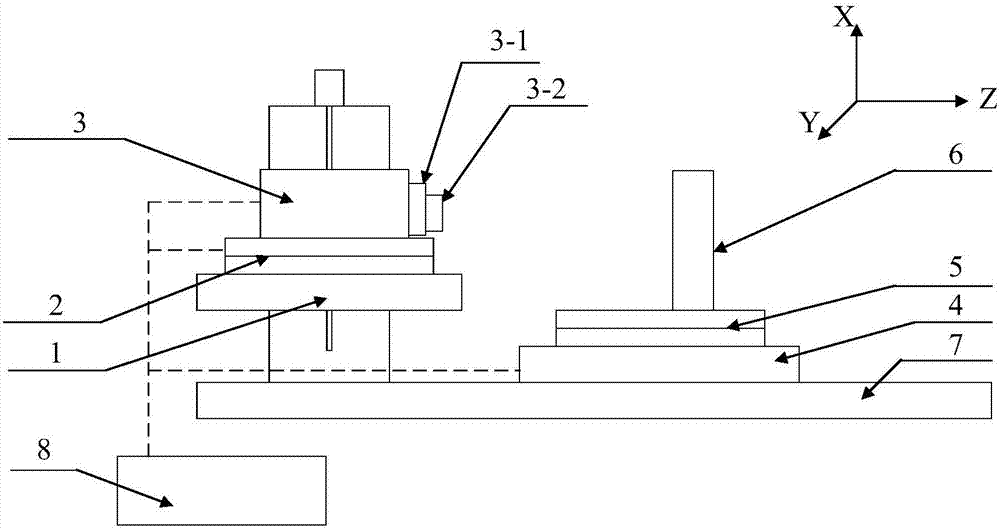

[0031] A planar surface-shaped sub-aperture splicing interference detection device, such as figure 1 As shown, it includes: interferometer 3, interferometer splicing translation platform 1, interferometer tilt adjustment platform 2, DUT splicing translation platform 4, DUT tilt adjustment platform 5, DUT 6, support platform 7, and control System 8;

[0032] Described interferometer 3 is the DynaFiz interferometer of U.S. Zygo Company, and measuring diameter is 100mm;

[0033] Described interferometer 3 comprises plane standard mirror 3-2 and standard mirror tilt adjustment frame 3-1; The reference plane place plane of described plane standard mirror 3-2 is the XY plane, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com