Ultraviolet curing coating

A technology of curing coatings and ultraviolet light, applied in epoxy resin coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of weak scratch resistance and poor pollution resistance, and achieve easy cleaning and strong adhesion. , Good anti-pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

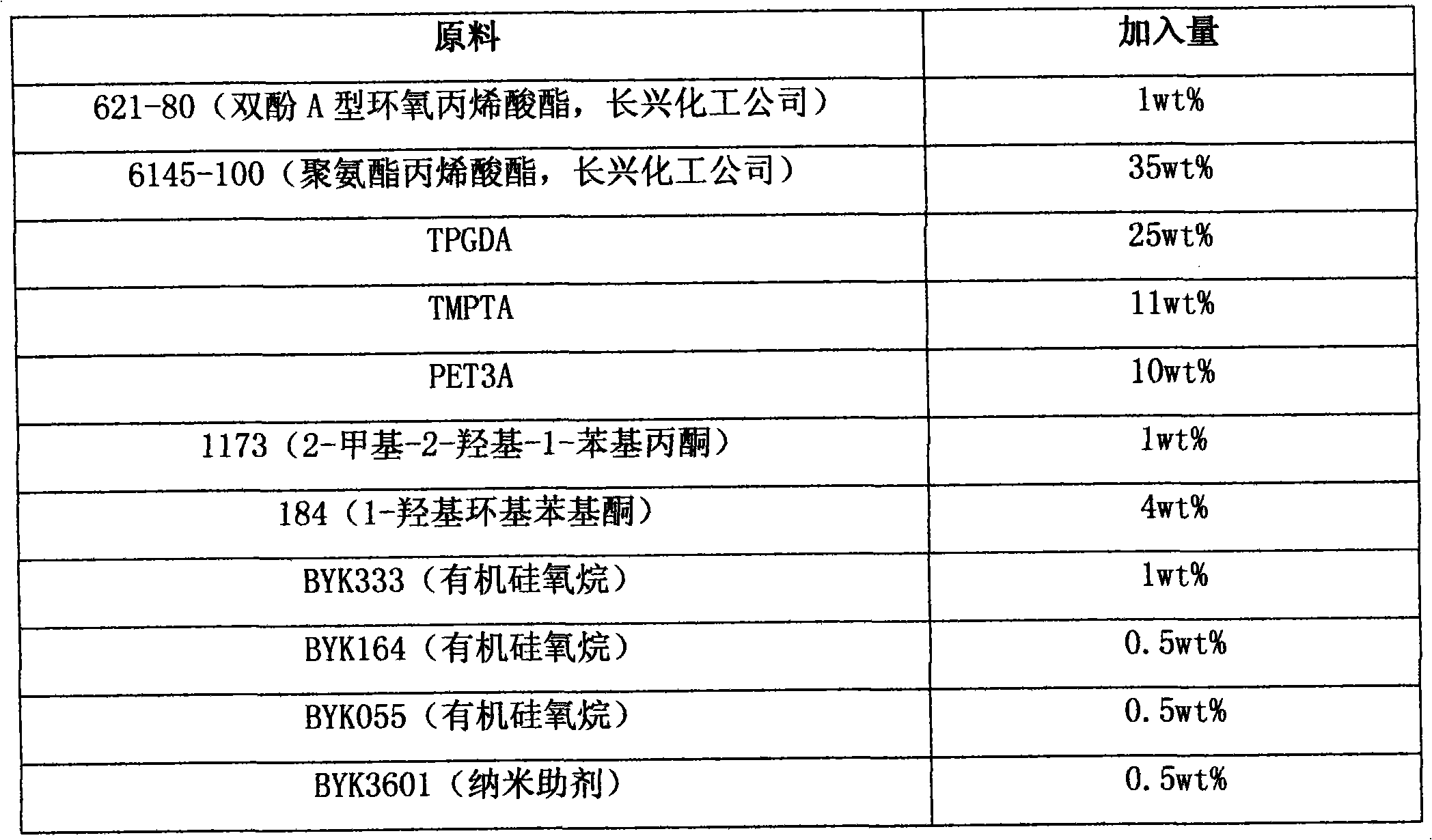

[0024] 1. Formulation Table 1

[0025]

[0026]

[0027] 2. Preparation process:

[0028] (1) Mix epoxy acrylate, urethane acrylate, multifunctional acrylate monomer and photoinitiator, heat up to 40-50°C, and stir until dissolved.

[0029] (2) Add additives to step (1), stir, cool down, and filter to obtain a UV-curable coating.

Embodiment 2

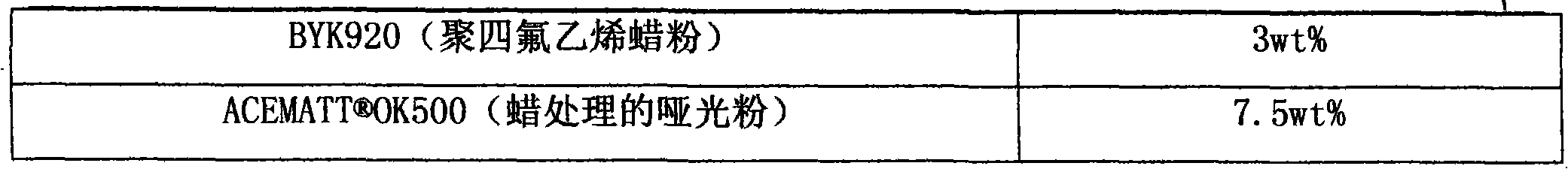

[0031] 1. Formula table 2

[0032]

[0033] 2. Preparation process: prepare according to the preparation process in Example 1.

Embodiment 3

[0035] 1. Formula table 3

[0036]

[0037]

[0038] 2. Preparation process: prepare according to the preparation process in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com