Ultraviolet curing liquid state optical cement and preparation method thereof

An optical glue and ultraviolet light technology, applied in the directions of adhesives, adhesive types, non-polymer adhesive additives, etc., can solve the problems of reducing the quality stability period of touch screen products, weak bonding strength, poor weather resistance, etc. The effect of transparency, high bond strength and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

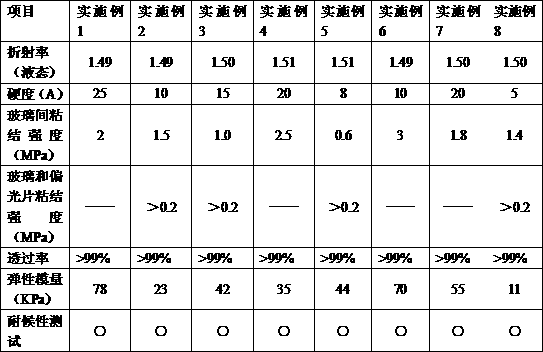

Examples

Embodiment 1

[0021] In this embodiment, the preparation method of UV-curable liquid optical adhesive includes the following steps in sequence:

[0022] (1) By weight, take 67 grams of urethane acrylate oligomers (all are urethane acrylates with an average viscosity of 50,000 cps, an average molecular weight of 50,000, and a functionality of 2. The urethane acrylate is composed of long-chain polyols, cyanate-based monomer and acrylic monomer), 20 grams of (meth)acrylate (both 1,4-cyclohexanedimethanol methacrylate), 5 grams of photoinitiator (both phenylbenzophenone), 6 grams of silane coupling agent (both vinyltriethoxysilane) and 2 grams of additives (both plasticizer bis(2-ethyl)hexyl adipate), and added to a clean and dry reaction vessel, and then the materials in the reaction vessel were stirred at a stirring speed of 1200 rpm until uniformly mixed (stirring time was 50 minutes) to obtain a rubber compound;

[0023] (2) Degas the glue obtained in step (1) with a vacuum degassing machi...

Embodiment 2

[0027] In this embodiment, the preparation method of UV-curable liquid optical adhesive includes the following steps in sequence:

[0028] (1) By weight, take 55 grams of urethane acrylate oligomers (all are urethane acrylates with an average viscosity of 40,000cps, an average molecular weight of 35,000, and a functionality of 1. The urethane acrylate is composed of long-chain polyols, cyanate-based monomer and acrylic acid monomer), 32 grams of (meth)acrylate (both isobornyl methacrylate), 2 grams of photoinitiator (both 2,2'-diethyl oxyacetophenone), 1 gram of silane coupling agent (both 3-methacryloxypropyltrimethoxysilane) and 10 grams of additives (both plasticizer di-n-hexyl sebacate), and Add it into a clean and dry reaction container, and then stir the materials in the reaction container at a stirring speed of 1500 rpm until they are evenly mixed (the stirring time is 30 minutes) to obtain a rubber compound;

[0029](2) Defoaming the rubber compound obtained in step (...

Embodiment 3

[0033] In this embodiment, the preparation method of the UV-curable liquid optical adhesive comprises the following steps in sequence:

[0034] (1) By weight, take 60 grams of urethane acrylate oligomers (both are urethane methacrylates with an average viscosity of 45,000cps, an average molecular weight of 40,000, and a functionality of 1.5, which are composed of long-chain polyols, Monomers with isocyanate groups and acrylic monomers are copolymerized), 33 grams of (meth)acrylates (including 20 grams of isooctyl methacrylate, 13 grams of isobornyl methacrylate), 0.2 grams of light Initiator (both 2-hydroxy-2-phenylacetophenone), 3 g silane coupling agent (both 3-(2,3-glycidoxy)propyltrimethoxysilane) and 3.8 g co-agent agent (in which light stabilizer bis(3,5-di-tert-butyl-4-hydroxybenzyl monoethyl phosphate) nickel 0.3 g, plasticizer triphenyl phosphate 3.5 g), and added to the clean, dry reaction In the container, then the material in the reaction container is stirred unti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average viscosity | aaaaa | aaaaa |

| Average viscosity | aaaaa | aaaaa |

| Average viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com