Ultraviolet light curing offset printing ink and preparation method thereof

An offset printing ink and ultraviolet light technology, applied in the field of offset printing light-curing ink and its preparation, and printing ink containing light-curing resin, can solve the problems of high ink requirements, decreased strength, difficult technology to break through, etc., and achieve color restoration. Good performance, shortened molding time, pure color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The preparation of embodiment 1 ultraviolet curing ink:

[0060] The raw material species and weight (Kg) formula used are:

[0061] (1) Cytec EB859 resin

5

(1) Taiwan Sony 705

5

(1) Cytec EB436 resin

12

(1) East Asia synthetic 8060 resin

5

(2) Sartomer CN2204 resin

5

(3) Zhongshan Chiba UV2630 resin

20

(4) TPGDA monomer

2

(4) HDDA monomer

1.5

(5) BASF LR9013 resin

5

(6) BASF 9026V resin

2

(8) 184 initiator

2

(8) ITX initiator

1

(8) 651 initiator

3

(8) 369 Initiator

1

(8) 907 initiator

3

(11) Clariant GRX-86 yellow

11

(11)LBL yellow

8.5

3

(7)TAA

3

(9) 510 polymerization inhibitor

0.5

(12) 32000 dispersant

0.5

1

total

100

[0062] Product...

Embodiment 2

[0069] The preparation of embodiment 2 ultraviolet curing ink:

[0070] The raw material species and weight (kg) formula used are:

[0071] (1) Sartomer CN2203 resin

5

(1) Cytec EB657 resin

3

(1) Cytec EB438 resin

18

(2) Sartomer CNUVE-150 resin

5

(3) Zhongshan Chiba UV2630 resin

8

(5) BASF LR9013 resin

10

(6) BASF 9026V resin

5

(4) TPGDA monomer

6

(8) 184 initiator

5

(8) ITX initiator

1

(8) 369 Initiator

1

(8) 907 initiator

1

(11) 57:1 Magenta

22

3

[0072] (7) Sartomer CD9051 adhesion promoting monomer

5

(9) ST-1 polymerization inhibitor

0.5

(12) BYK163 dispersant

0.5

(12) wax powder

1

total

100

[0073] Production Method:

[0074] ①Mix 10kg of LR9013 grinding and dispersing resin, 18kg of EB438 re...

Embodiment 3

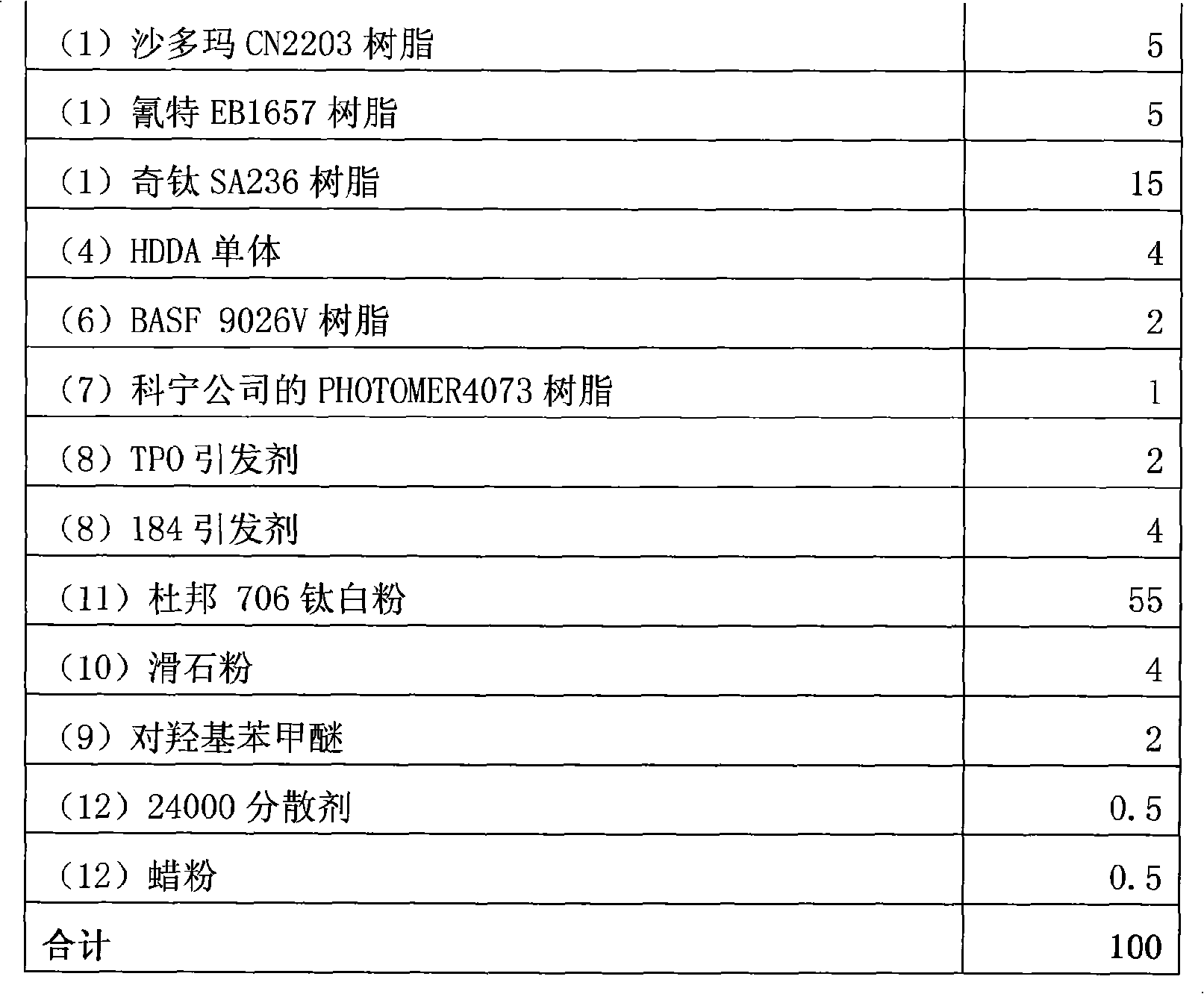

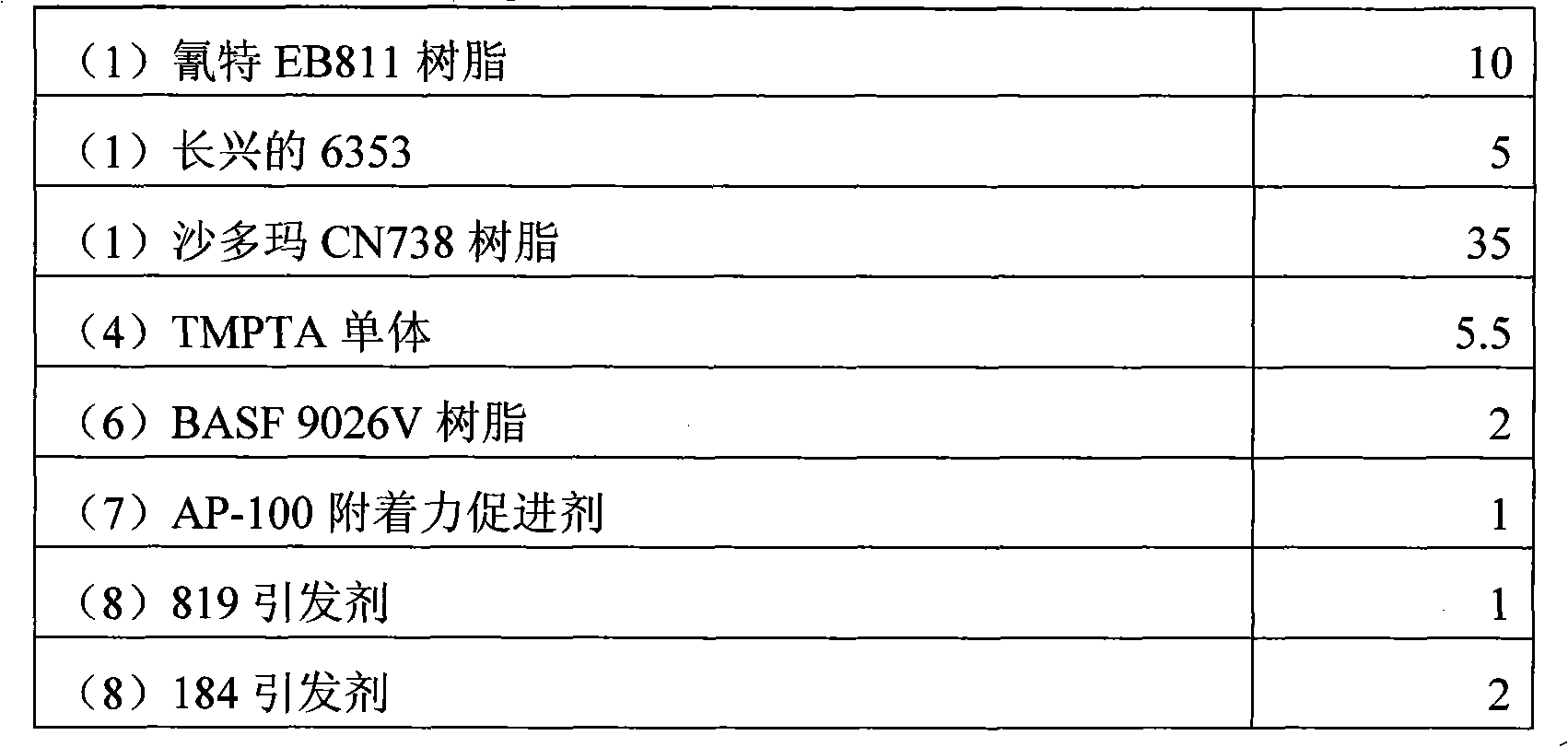

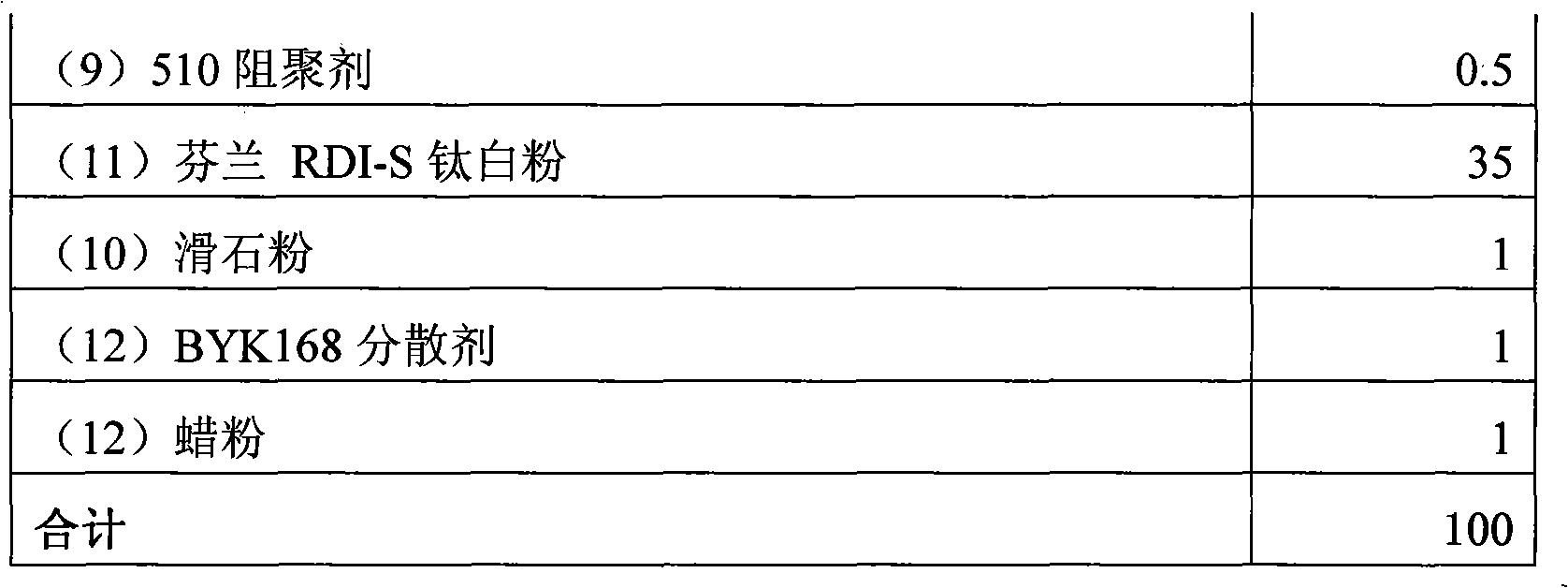

[0081] The preparation of embodiment 3 ultraviolet curable inks:

[0082] The raw material species and weight (kg) formula used are:

[0083] (1) EB1657

7

(1) Sartomer CN750 resin

14

(1) Changxing's 6350 resin

5

(3) Zhongshan Chiba UV2630 resin

10

(4) TMPTA monomer

15

[0084] (6) BASF 9026V resin

5

(5) BASF LR9013 resin

10

(8) 651 initiator

3

(8) ITX initiator

1

(8) EDAB initiator

1

(8) 907 initiator

4

(7) PHOTOMER4073 resin of Corning Company

2

(9) ST-1 polymerization inhibitor

0.5

(12) BYK168 dispersant

0.5

(11) 5412SD blue powder

19

(10)M-5

2

(12) wax powder

1

total

100

[0085] Production Method:

[0086] ①Mix 10kg of LR9013 grinding and dispersing resin, 7kg of EB1657 resin, 5kg of 6350 resin, 14kg of CN750 resin, 10kg of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| tackiness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com