Preparation method and application of resin having double curing groups

A dual-curing, group technology, applied in the field of synthesis of urethane acrylate-modified epoxy acrylic monoester, can solve the problems of uneven local curing, poor resin compatibility, etc., to improve the shrinkage rate and enhance the bonding performance , the effect of reducing the double bond density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In the first step, add 260g of bisphenol A epoxy (epoxy E51) into a 500mL three-necked flask, take an oil bath to 100°C, stir, and add additionally metered acrylic acid (the molar ratio of epoxy group to acrylic acid is 2:1) Add a total mass of 0.2% catalyst N,N-dimethylbenzylamine (BDMA) and 0.3% polymerization inhibitor p-hydroxyanisole, dropwise into the epoxy resin, and react for 4.5h after the acid value of the system is less than 3mgKOH / g , that is, the epoxy acrylate monoester ①; the second step, in a 500mL three-necked flask, add 2mol of toluene diisocyanate (TDI), heated to 60 ° C, dibutyltin dilaurate is added by 0.2% of the total mass Add 1 mol of polyethylene glycol (molecular weight 400) dropwise into the toluene diisocyanate (TDI) solution, continue the reaction for 2 hours after the drop, add 0.2% p-hydroxyanisole to 1 mol of hydroxyethyl acrylate, add the above reaction system, heated up to 100°C and reacted for 2.5 hours to obtain polyurethane acrylate ...

Embodiment 2

[0031]In the first step, add 550g of bisphenol A epoxy (epoxy E44) into a 1000mL three-necked flask, take an oil bath to 110°C, stir, and add additionally metered acrylic acid (the molar ratio of epoxy group to acrylic acid is 2:1) Add a total mass of 0.4% catalyst triethylbenzyl ammonium chloride and 0.3% polymerization inhibitor hydroquinone, drop into the epoxy resin, and react for 4 hours. The acid value of the system is less than 3mgKOH / g, that is, the epoxy acrylic acid Monoester ①; in the second step, add 2mol of diphenylmethane diisocyanate (MDI) in a 500mL three-necked flask, heat to 60°C, and dibutyltin dilaurate is added to 1mol of poly Add ethylene glycol (molecular weight 600) dropwise into the toluene diisocyanate (TDI) solution, continue the reaction for 2 hours after the drop is complete, add 0.3% p-hydroxyanisole to 1mol of hydroxyethyl methacrylate, and add the above reaction system , heated to 100°C and reacted for 2.5 hours to obtain polyurethane acrylate ②...

Embodiment 3

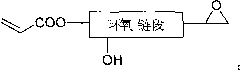

[0033] In the first step, add 600g of tetrabromobisphenol A epoxy resin into a 1000mL three-necked flask, heat the oil bath to 90°C, stir, and then add The total mass of 0.5% catalyst tris(acetylacetonate) lanthanum (III) and 0.5% polymerization inhibitor p-hydroxyanisole are added dropwise in the epoxy resin, and the acid value of the system is less than 3mgKOH / g after reacting for 5 hours, that is, the epoxy Acrylic monoester ①; in the second step, add 3mol of hexamethylene diisocyanate (HDI) in a 1000mL three-necked flask, heat to 80°C, and add 0.2% of dibutyltin dilaurate to 1mol of Add 1,6-hexanediol dropwise into the toluene diisocyanate (TDI) solution, continue the reaction for 2 hours after the drop is complete, add 0.5% p-hydroxyanisole to 1mol of hydroxypropyl acrylate, add the above reaction system, and heat up React at 80°C for 3 hours to obtain urethane acrylate ② with -NCO group at one end; in the third step, add a certain amount of epoxy acrylate monoester ① int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com