Ultraviolet curing transfer adhesive

A technology of transfer glue and ultraviolet light, applied in adhesives, non-polymer organic compound adhesives, etc., can solve problems such as poor environmental protection, brittle materials, and large construction limitations, so as to reduce energy consumption and increase yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

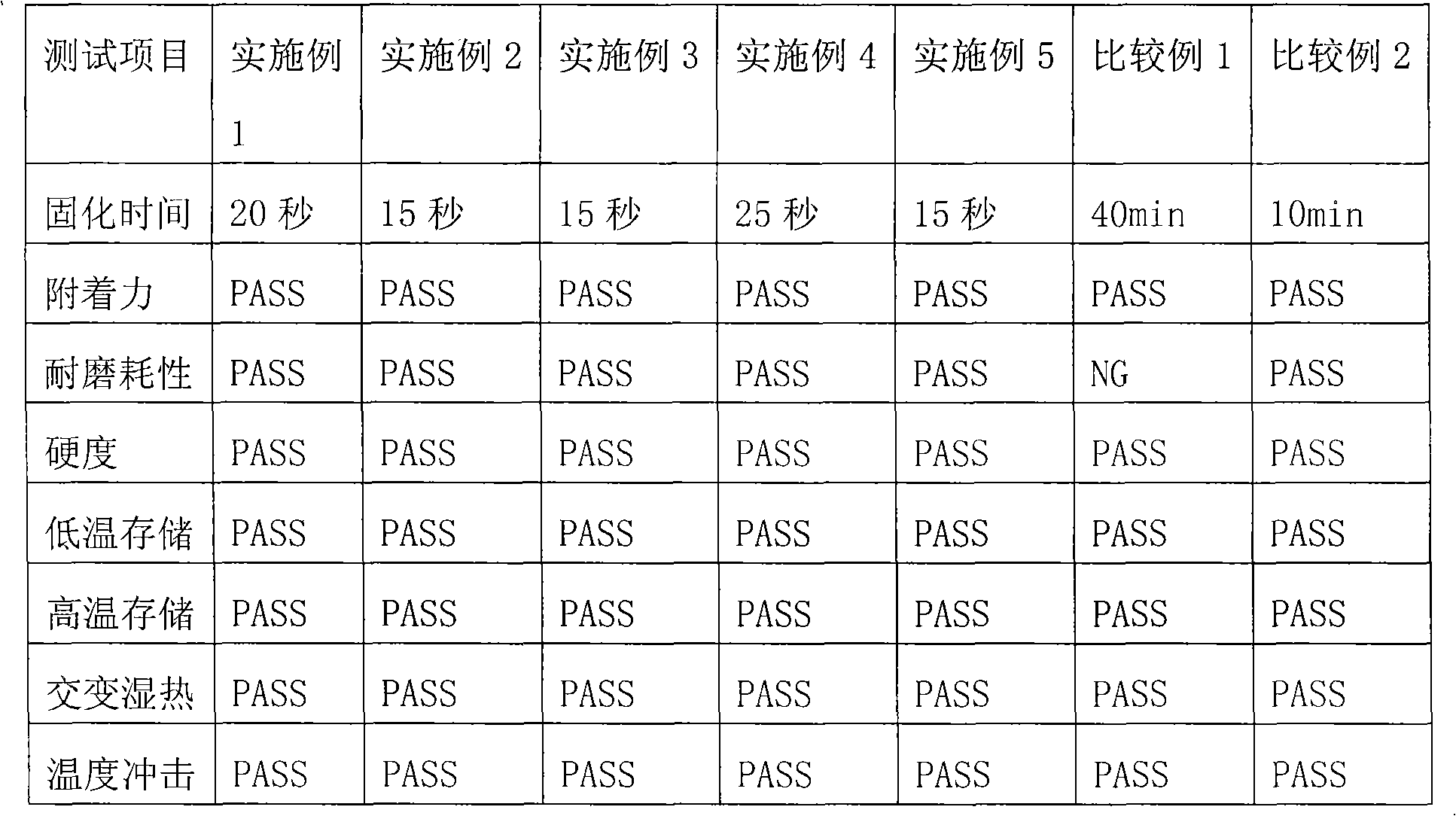

[0053] An ultraviolet light curing transfer adhesive, which is composed of the following raw materials in weight percentage: 20% epoxy acrylate, 40% polyurethane acrylate, 10% isobornyl acrylate, 25% tripropylene glycol diacrylate, 1-hydroxyl ring Hexyl phenyl ketone 2%, 2,4,6-trimethylbenzoyl-diphenylphosphine oxide 1%, vinyltrimethoxysilane 2%. According to the preparation method commonly used by those skilled in the art introduced in the present invention, the UV-curable transfer adhesive has a short curing time, can greatly reduce energy consumption, and improve the yield. Rubber printing, the test performance is superior, as shown in Table 1.

Embodiment 2

[0055] An ultraviolet light curing transfer adhesive, which is composed of the following raw materials in weight percentage: 50% polyurethane acrylate, 15% isobornyl acrylate, 30% hexanediol diacrylate, 1-hydroxycyclohexyl phenyl ketone 2 %, 2,4,6-trimethylbenzoyl-diphenylphosphine oxide 1%, vinyltrimethoxysilane 2%. According to the preparation method commonly used by those skilled in the art introduced in the present invention, the UV-curable transfer adhesive has a short curing time, can greatly reduce energy consumption, and improve the yield. Rubber printing, the test performance is superior, as shown in Table 1.

Embodiment 3

[0057] An ultraviolet light curing transfer adhesive, which is composed of the following raw materials in weight percentage: 10% epoxy acrylate, 15% polyester acrylate, 30% polyurethane acrylate, 20% hexanediol diacrylate, tricyclic Decane dimethanol diacrylate 10%, tetrahydrofuran acrylate 10%, 1-hydroxycyclohexyl phenyl ketone 2%, 2,4,6-trimethylbenzoyl-diphenylphosphine oxide 1%, ethylene Trimethoxysilane 2%. According to the preparation method commonly used by those skilled in the art introduced in the present invention, the UV-curable transfer adhesive has a short curing time, can greatly reduce energy consumption, and improve the yield. Rubber printing, the test performance is superior, as shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com