New method for preparing water-soluble carboxymethyl chitosan from chitin

A technology of carboxymethyl chitosan and chitin, which is applied in the field of preparing water-soluble carboxymethyl chitosan, can solve the problem that the degree of carboxylation is easily affected by temperature fluctuations, there are many by-products such as diglycolic acid, and there are irritating Sex and corrosiveness and other issues, to shorten the production process, improve the production environment, non-irritating and corrosive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

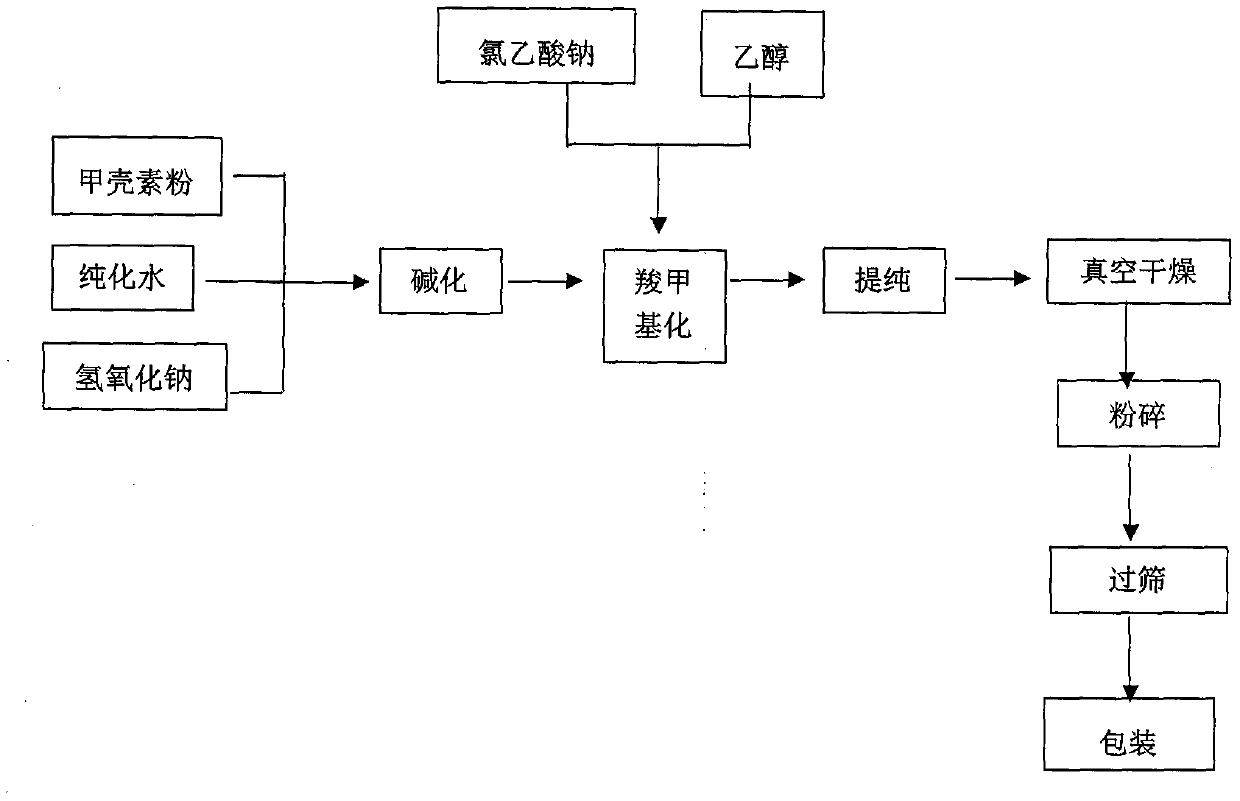

Image

Examples

Embodiment 1

[0021] Add 20g of chitin powder to a beaker equipped with an electric stirrer, prepare 200g of 45% NaOH solution, pour it into the chitin powder, stir for 1.5h to alkalize, separate solid and liquid, add 120ml of 95% ethanol, and stir evenly Add 40g of sodium chloroacetate, react at 60°C for 3.0 hours, separate the solid and liquid after the reaction, adjust the pH to neutral with dilute acid, wash twice with 200ml of 75% ethanol solution, dehydrate once with 100ml of 95% ethanol , vacuum-dried to obtain the product, according to the method in "YY0953-2015 Medical Carboxymethyl Chitosan", the pH was 7.0, the degree of substitution was 96.1%, the degree of deacetylation was 81.7%, and the purity was 86.3%.

Embodiment 2

[0023] Add 20g of chitin powder to a beaker equipped with an electric stirrer, prepare 200g of 45% NaOH solution, pour it into the chitin powder, stir for 1.5h for alkalization, separate solid and liquid, add 150ml of 95% ethanol, and stir well Then add 50g of sodium chloroacetate, react at 65°C for 3.5 hours, separate the solid and liquid after the reaction, adjust the pH to neutral with dilute acid, wash twice with 200ml of 75% ethanol solution, and dehydrate with 100ml of 95% ethanol Once, the product was vacuum-dried to obtain a pH of 7.2 according to the method in "YY0953-2015 Medical Carboxymethyl Chitosan", the degree of substitution was 92.3%, the degree of deacetylation was 78.9%, and the purity was 90.8%.

Embodiment 3

[0025] Weigh 10kg of chitin raw material and put it into a stirring tank, prepare 100kg of NaOH solution with 45% concentration, stir and alkalize at room temperature for 2 hours, separate solid and liquid, add 60kg of 95% concentration ethanol solution, and then add 20kg of sodium chloroacetate to In the system, the reaction was carried out at 60°C for 5.0 hours. After the reaction, the crude product was dissolved in purified water, filtered through a 3 μm precision filter, precipitated with 95% ethanol solution, separated from solid and liquid, adjusted to neutral with dilute acid, and washed twice with 75% ethanol solution. % concentration ethanol was dehydrated once, vacuum-dried, pulverized and passed through an 80-mesh sieve to obtain the product. After testing, the pH of the product is 7.3, the degree of substitution is 111.2%, the degree of deacetylation is 87.9%, and the purity is 94.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

| degree of deacetylation | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com