Method for controllably synthesizing near-infrared silver telluride quantum dots

A technology of quantum dots and silver telluride, applied in the fields of chemistry and nanomaterial preparation, can solve the problems of morphology, precise control of crystallinity, difficulty in achieving the size of quantum dots, and increase of synthesis cost, and achieves stable and controllable synthesis process. Uniform size and reduced usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

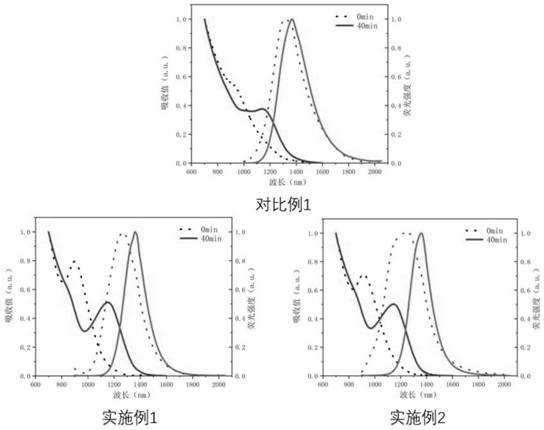

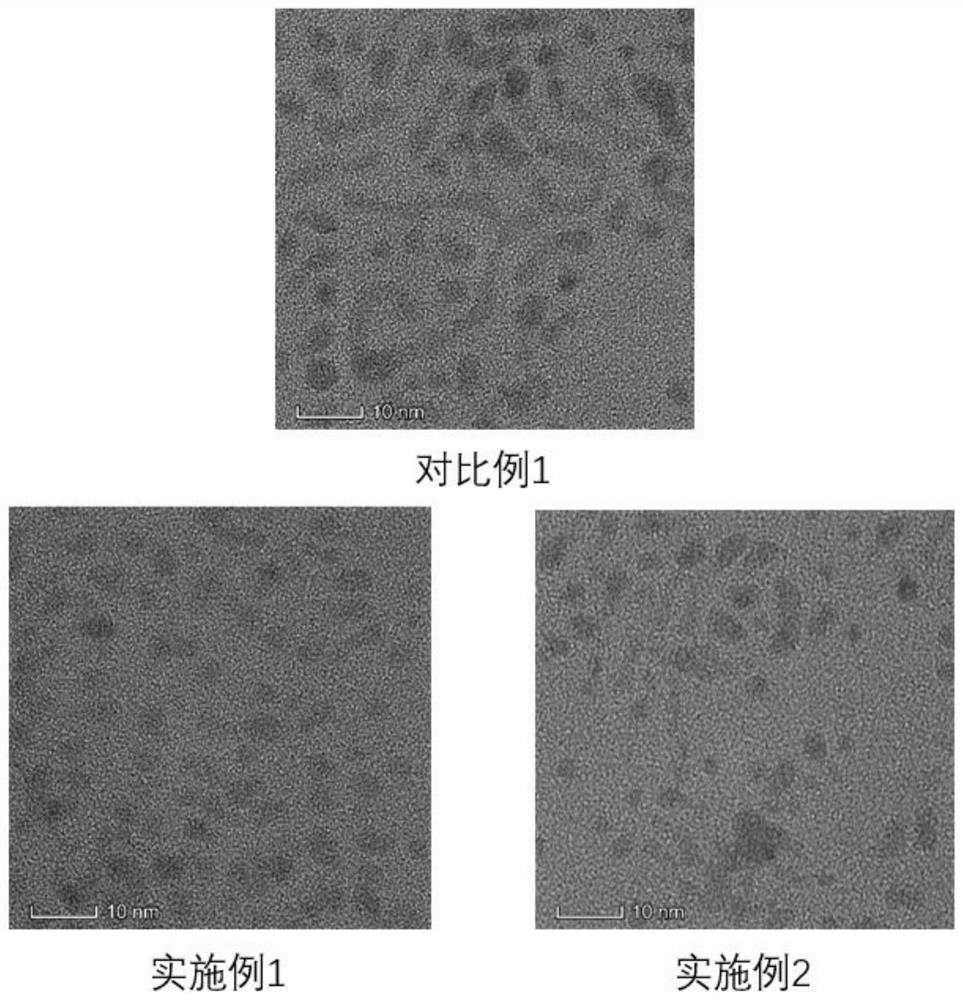

[0040] Embodiment 1: Preparation of silver telluride quantum dots

[0041] (1) Preparation of tellurium precursor: Weigh 81.6 mg of tellurium powder into a 50 mL three-necked flask, add 6 mL of tri-n-octylphosphine, stir and heat at 270 ° C in air for 10 min to obtain a yellow-green clear solution, cool to room temperature for later use .

[0042] (2) Synthesis and purification of silver telluride quantum dots: Add 4.5mL of 1-octadecene into a 50mL three-necked flask, pass argon gas at 100°C for 10min, add 75.2mg of silver acetate and 0.585mL of n-octyl mercaptan, and The temperature was raised to 110°C, and 0.225mL of tri-n-octylphosphine was added, and then the temperature of the mixture was raised to 160°C, and 0.0702mL of tellurium precursor was quickly injected to rapidly drop the temperature to 150°C. The solution was cooled to room temperature, 35 mL of acetone was added, centrifuged at 10,000 rpm for 10 min, the resulting precipitate was dispersed in tetrachloroethyle...

Embodiment 2

[0043] Embodiment 2: Preparation of silver telluride quantum dots

[0044] (1) Preparation of tellurium precursor: Weigh 81.6 mg of tellurium powder into a 50 mL three-necked flask, add 6 mL of tri-n-octylphosphine, stir and heat at 270 ° C in air for 10 min to obtain a yellow-green clear solution, cool to room temperature for later use .

[0045] (2) Synthesis and purification of silver telluride quantum dots: Add 4.5mL of 1-octadecene into a 50mL three-necked flask, pass argon gas at 100°C for 10min, add 75.2mg of silver acetate and 0.585mL of n-octyl mercaptan, and The temperature was raised to 110°C, 118 mg of triphenylphosphine was added, and then the mixture was heated to 160°C, and 0.0702 mL of tellurium precursor was quickly injected to rapidly drop the temperature to 150°C, and reacted at this temperature for 40 minutes, and the solution was cooled to At room temperature, add 35 mL of acetone, centrifuge at 10,000 rpm for 10 min, disperse the obtained precipitate in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com