Method for squeezing and extracting wheat-germ oil at low temperature

A technology for wheat germ oil and an extraction method, which is applied to the field of low-temperature pressing and extraction of wheat germ oil, can solve the problems of inability to obtain full-fat wheat germ oil, high investment cost of extraction method, large loss of nutrient components, etc., and achieves low investment and low cost. , the effect of small loss of nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

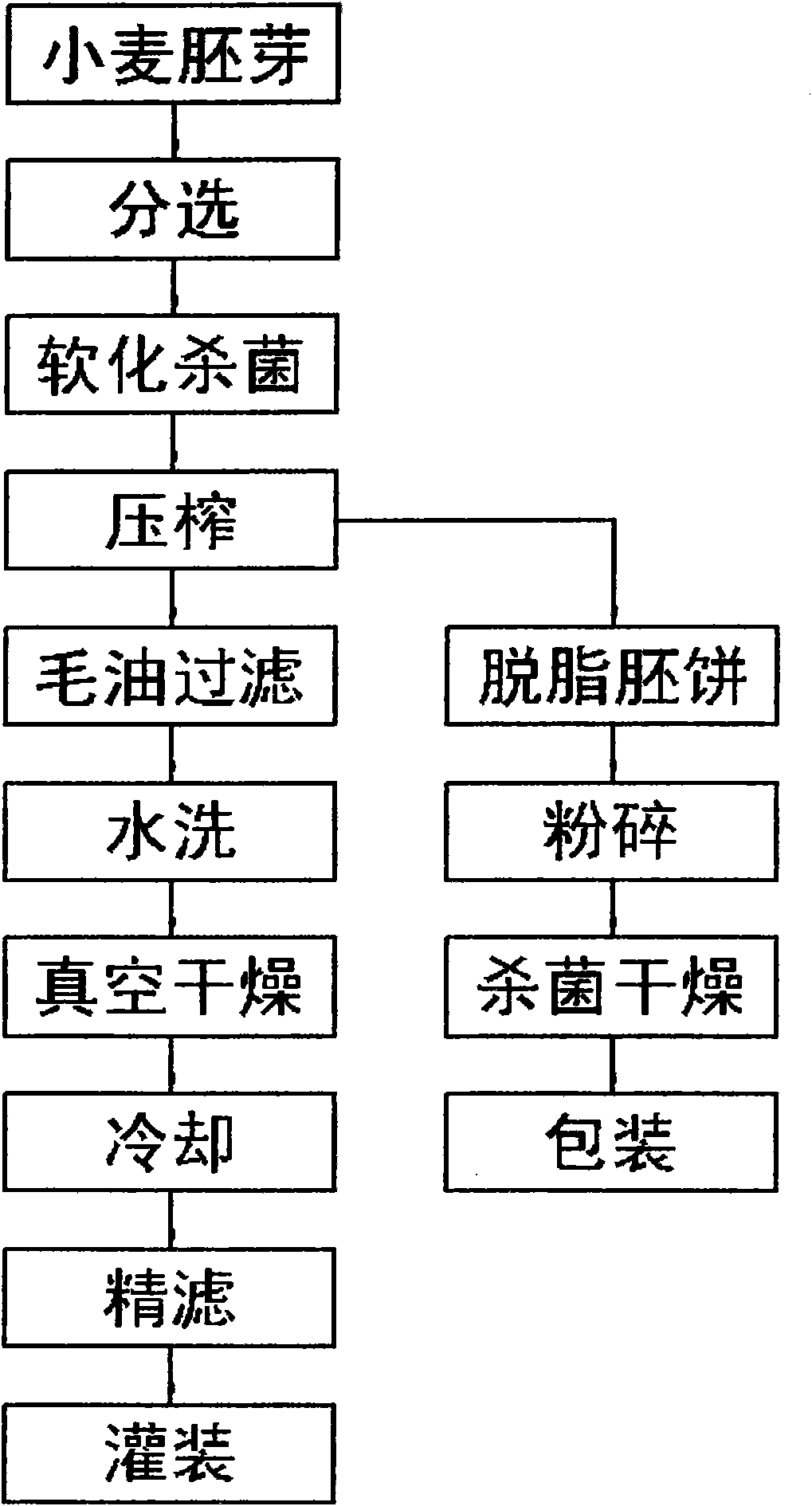

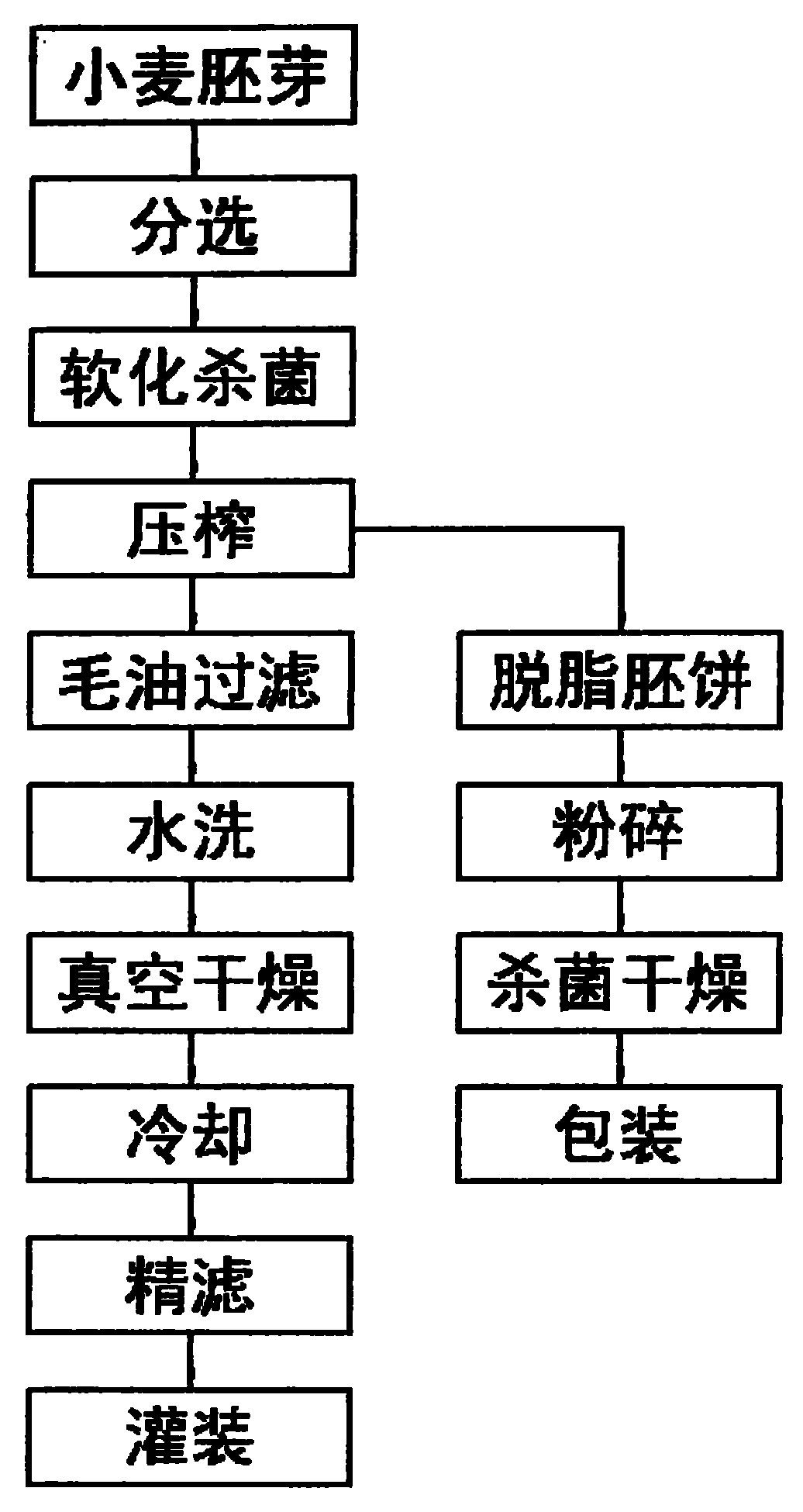

[0016] The following combination figure 1 The present invention will be further described with reference to specific embodiments.

[0017] A method for extracting wheat germ oil by low-temperature pressing, comprising the following steps:

[0018] The fresh wheat germ is passed through a sorting machine to remove the flour and bran in the wheat germ, and the purity reaches 99%;

[0019] Softening and sterilization treatment, steam the wheat germ in a softening pot for 25-35 minutes, control the stirring speed at 20 rpm, and control the temperature at 75-80°C to expand the wheat germ molecules and increase plasticity. After stopping the steam, continue to cultivate Stir-fry, when the moisture content of the wheat germ drops to 10%, it can be squeezed.

[0020] Automatic oil pressing: After the oil press is loaded with embryos, press the operation button of the oil press, and the oil press will enter the automatic operation state. The microcomputer will automatically complete ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com