Airplane landing gear loading device and method

A technology of aircraft landing gear and loading device, which is applied to measurement devices, testing of mechanical components, testing of machine/structural components, etc., can solve problems such as failure to achieve the purpose of assessment, data errors, and failure to achieve the most accurate structural assessment. , to achieve the effect of low processing requirements, guaranteed stability and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiments of the present invention will be described in detail with reference to the summary of the invention and the accompanying drawings.

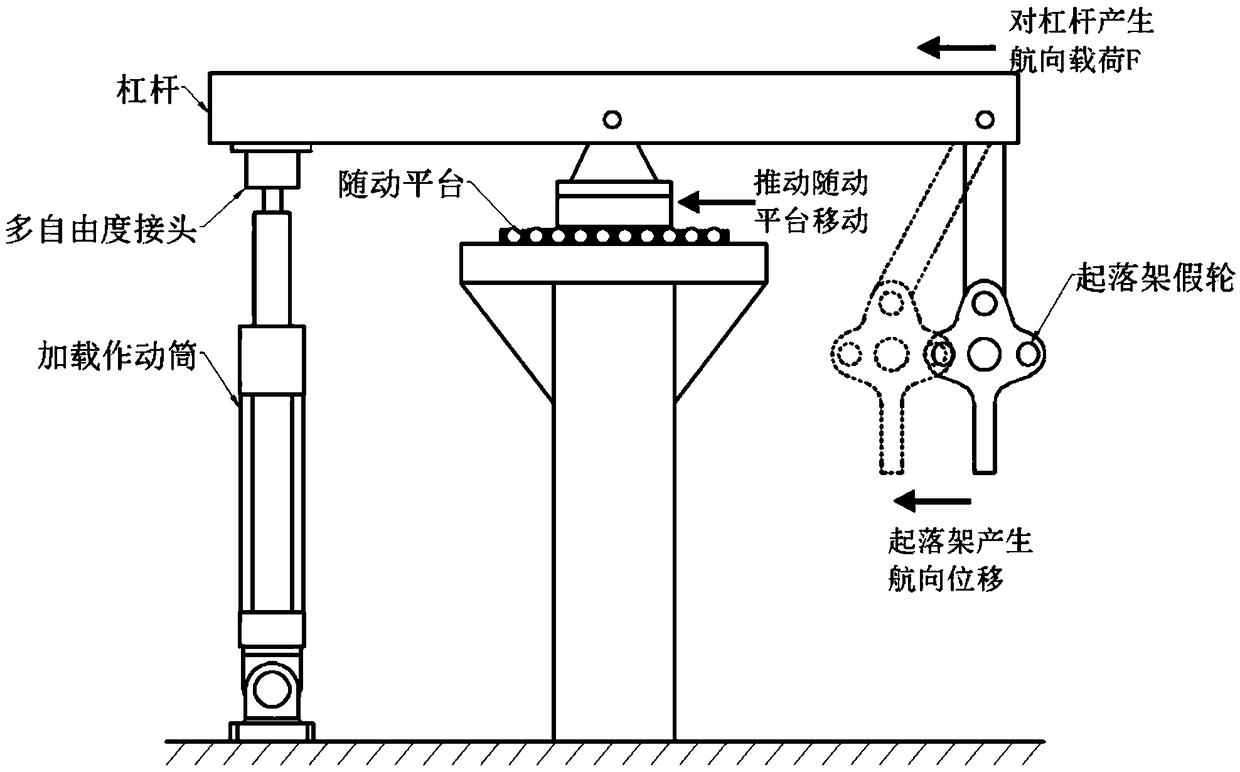

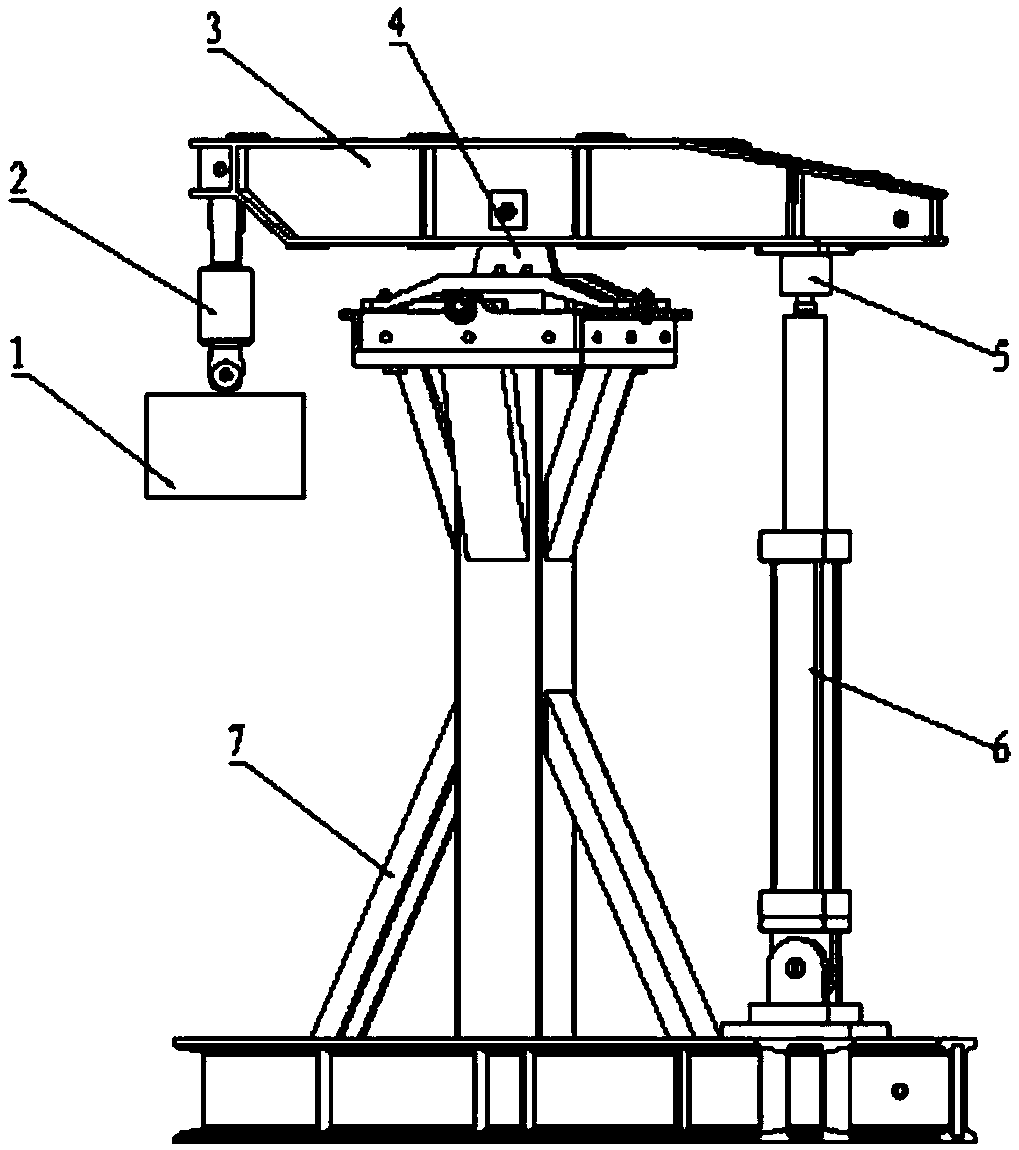

[0017] An aircraft landing gear loading device, comprising a horizontally arranged loading crowbar 3, the loading crowbar 3 transmits the load from one end to the landing gear end, and one end of the loading crowbar 3 is vertically connected with a landing gear dummy wheel 1, the landing gear dummy wheel 1 is the landing gear loading structure. A load cell 2 is connected between the loading crowbar 3 and the landing gear dummy wheel 1, which can control and feedback the load size, and the other end is connected with a hydraulic actuator for loading through a multi-degree-of-freedom joint. The telescopic end of 6, the multi-degree-of-freedom joint can use the universal joint 5. The universal joint 5 is a load transmission device during the loading process to ensure that there will be no jamming during the loading and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com