Expendable pattern casting method for manufacturing aerogenerator mainshaft by ductile cast iron

A technology of wind power generators and lost foam casting, which is applied in the manufacture of tools, casting molding equipment, casting molds, etc. It can solve the problems of large gasification of patterns, poor strength of castings, and performance that cannot meet the requirements, so as to simplify production process, reduce production cost, and meet the effect of market demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

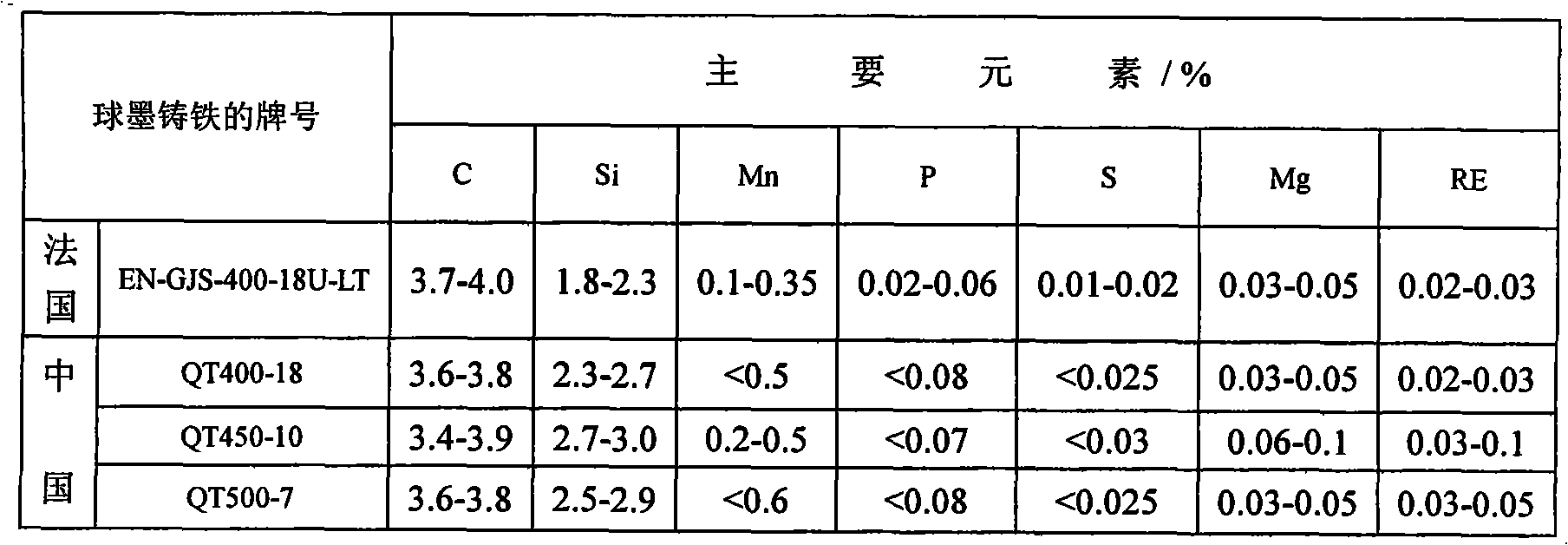

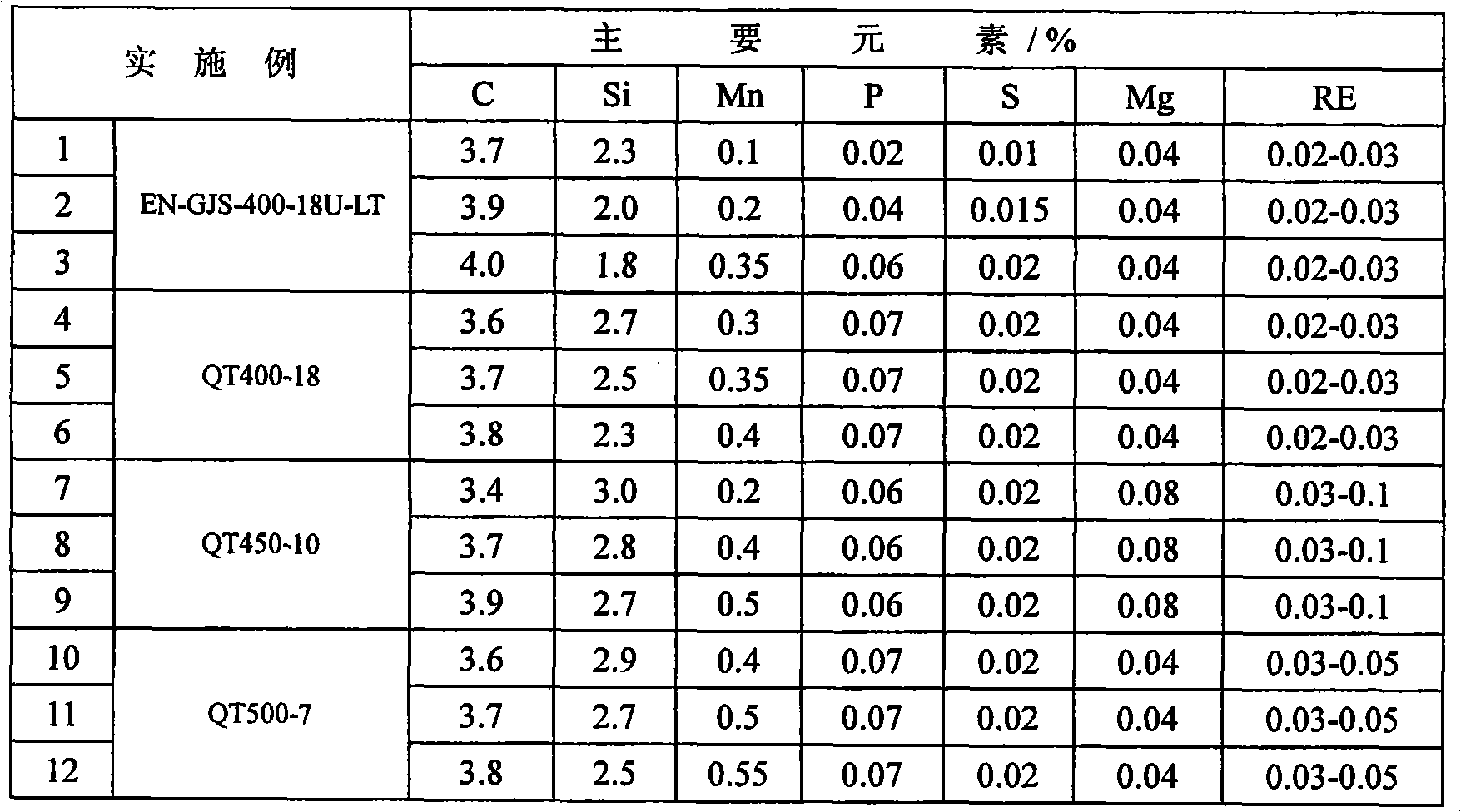

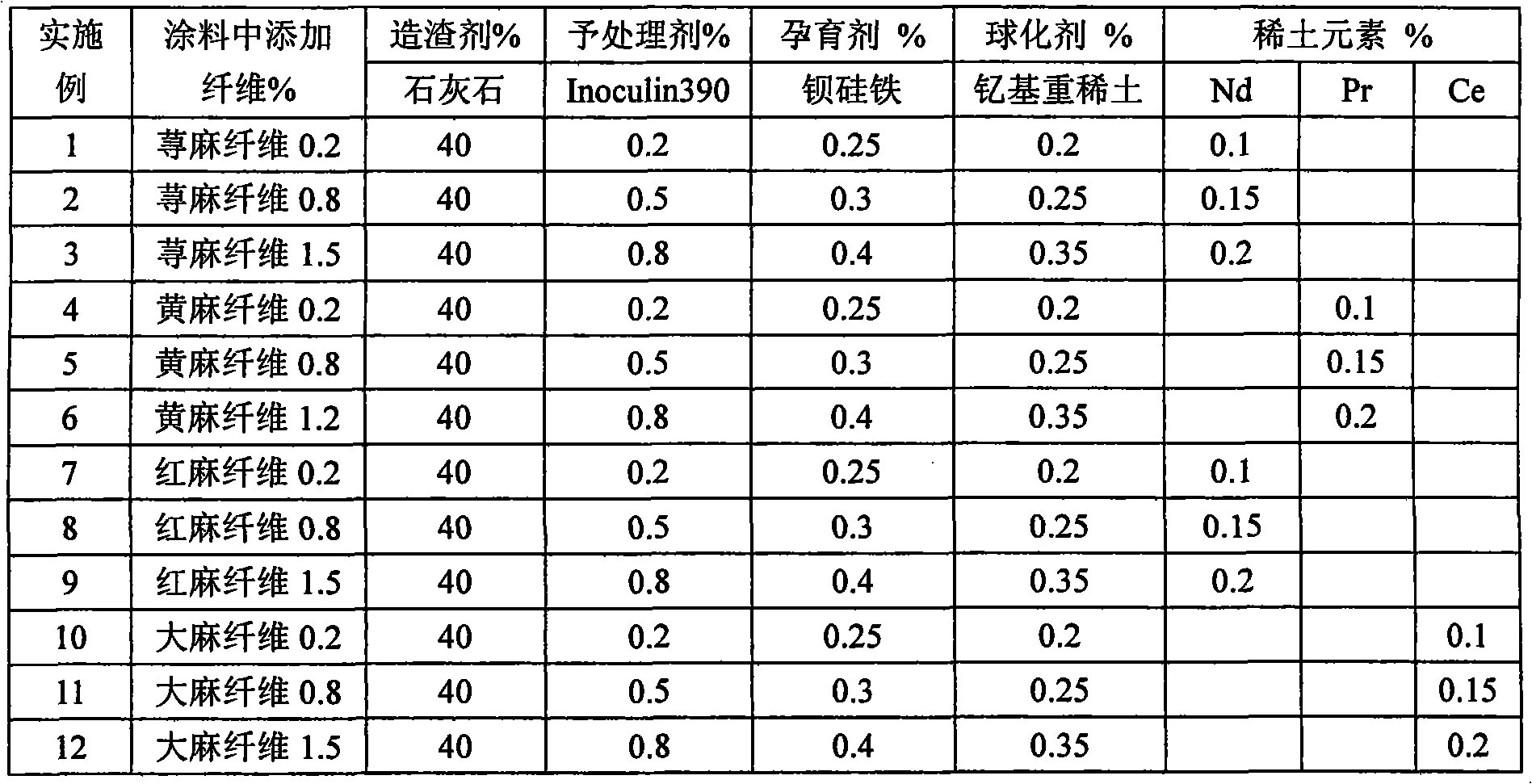

Embodiment 1~12

[0022] 1) First, press polystyrene foam plastic into each section of the step-shaped fan spindle blank, and then paint the refractory coating made of quartz powder, bauxite, and graphite powder according to the conventional ratio and dry it. Quartz powder SiO used in refractory coatings2 >97%, particle size 200-270 mesh; Al in bauxite 2 o 3 ≥75%, and is a high-alumina clinker after high-temperature calcination, with a particle size greater than 300 mesh. Wherein also add the hemp fiber of 0.2-1.5% by paint weight, to increase the gas permeability of paint. The amount added in each embodiment is shown in Table 3. The hemp fiber is any one of nettle fiber, jute fiber, kenaf fiber or hemp fiber.

[0023] 2) First take a positioning shaft set at the axis position of the sand box assembly fan main shaft module as the center line, then glue the dried sections of the modules one by one to make the final shape, and remove the positioning shaft. Fill the sand box with natural round...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com