Method for cutting metal nano structure to assemble the same into nano device and method of in-situ characterization for nano device

A technology of metal nanostructures and nanodevices, applied in the field of nanomanufacturing, can solve problems such as high equipment threshold, device pollution, and difficult control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

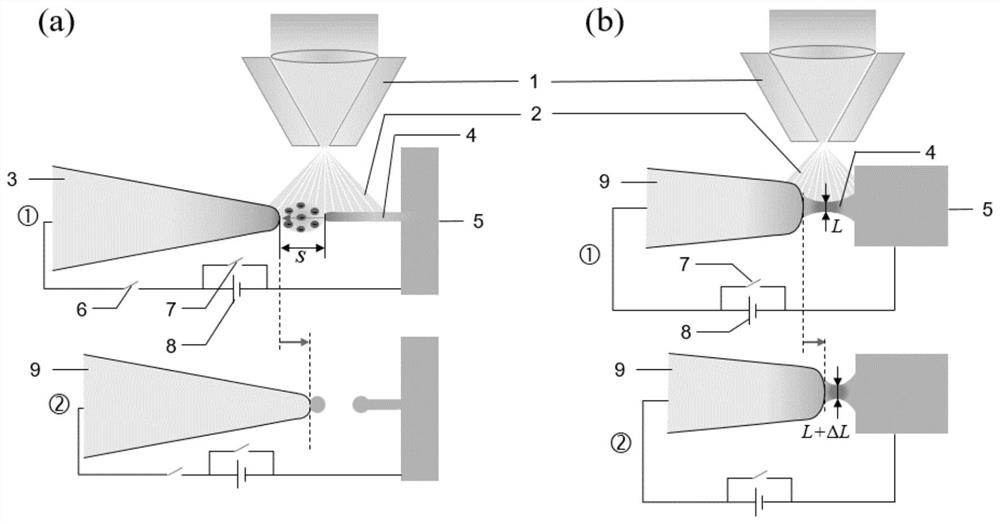

Method used

Image

Examples

Embodiment 1

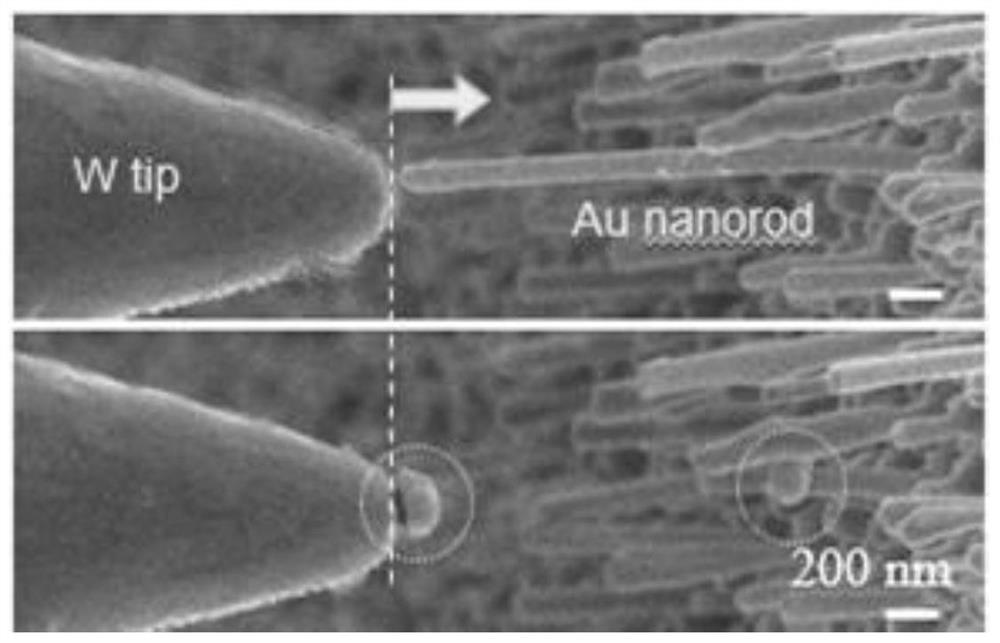

[0068] 1) Fix the Au substrate with Au nanocolumn arrays on the surface prepared by superplastic nano-casting on the sample stage of the scanning electron microscope, and fix a tungsten probe on a nano-manipulator installed in the scanning electron microscope. The manipulator has degrees of freedom in three directions and the movement accuracy can be better than 1 nanometer. First connect the tungsten needle tip to the Au substrate through a short-circuit through the output end of the nanomanipulator;

[0069] 2) When the electron beam of the scanning electron microscope is turned on (usually the acceleration voltage of the electron beam is set to be greater than or equal to 1 kV and less than or equal to 20 kV), the nanomanipulator is driven in situ to move, so that the tungsten tip approaches and touches an Au nanopillar , and then retract the tungsten probe to make it spaced from the Au nanocolumn at a certain distance (usually less than 2 microns), and simultaneously disconn...

Embodiment 2

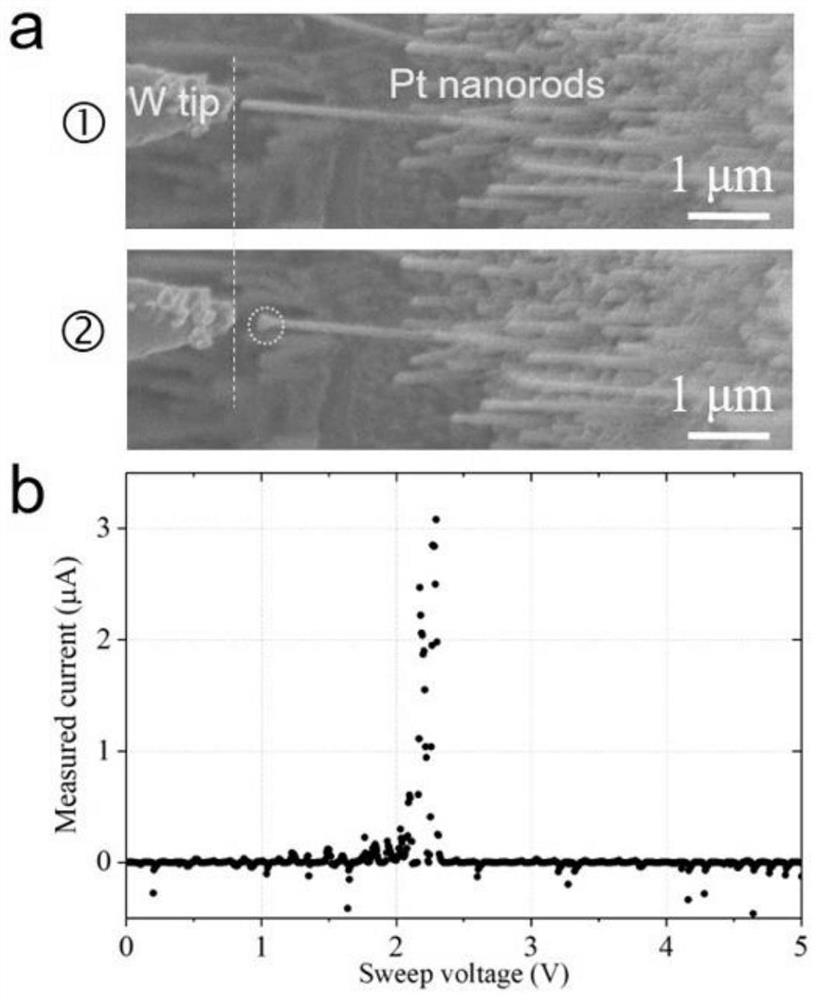

[0072] 1) Fix the Pt substrate with the Pt nanocolumn array on the surface prepared by superplastic nanomolding on the sample stage of the scanning electron microscope, and connect it to the tungsten tip installed on the nano manipulator through a wire short circuit;

[0073] 2) Drive the nanomanipulator to move in situ under the condition that the electron beam of the scanning electron microscope is turned on, so that the tungsten tip approaches and touches a Pt nanocolumn, and then retracts the tungsten probe so that it is separated from the Pt nanocolumn by a certain distance (usually less than 1 Micron), disconnect the wire between the tungsten tip and the Au substrate at the same time, and respectively connect the tungsten tip and the Pt substrate to the positive and negative poles of a voltage source, but the power supply of the voltage source is turned off;

[0074] 3) Drive the tungsten probe close to the Pt nanocolumn. During this process, the Pt nanocolumn is partiall...

Embodiment 3

[0078] The specific process steps for preparing a typical Pt-Ag nano-heterojunction device are as follows:

[0079] 1) Take the method steps of the aforementioned embodiments to first make a tungsten tip welded with a Pt nanocolumn;

[0080] 2) Replace the Pt sample on the SEM sample stage with an Ag substrate, and short-circuit the tungsten tip with the Pt nanocolumn welded to the Ag substrate;

[0081] 3) Drive the nanomanipulator to move in situ when the electron beam of the scanning electron microscope is turned on, so that the tungsten tip approaches and contacts an Ag nanopillar on the Ag substrate;

[0082] 4) Disconnect the short-circuit connection between the tungsten tip and the Ag substrate, apply a small voltage between the tungsten tip and the Ag substrate, and continuously increase the input voltage until welding occurs between the Pt nanocolumn and the Ag nanocolumn;

[0083] 5) Drive the tungsten tip to reciprocate and stretch and move laterally, so that the A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com