Preparation process of calcium stannate ceramic material precursor

A ceramic material and preparation technology, which is applied in the field of new preparation technology of calcium stannate ceramic material precursor, can solve the problems of low conversion rate of SnO2, complex process of calcium stannate, low product purity, etc., shorten the roasting time, reduce The effect of secondary pollution and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

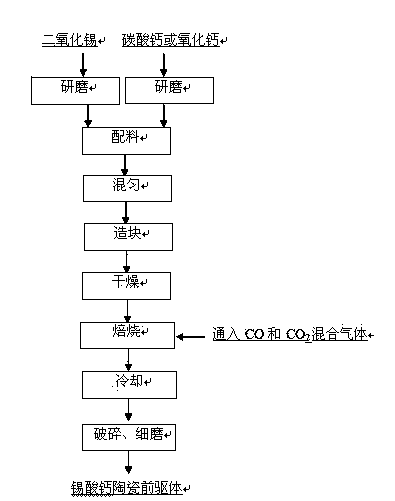

Method used

Image

Examples

Embodiment 1

[0038] Chemically pure tin dioxide (SnO 2 content of 99.15%) and calcium carbonate (CaCO 3 Content is 99.5%) as raw material. Mix the finely ground tin dioxide and calcium carbonate in a molar ratio of 1:1, add 1% slaked lime and 12% water, and mix evenly; then use a disc pelletizer to pellet the mixture, and after drying , placed in a controlled-atmosphere static muffle furnace for heating and roasting, the roasting temperature was 900°C, the roasting time was 30min, and the roasting atmosphere consisted of CO and CO 2 The composition of the mixed gas, where the volume concentration of CO [CO / (CO+CO 2 )] is 15%. After the calcined mass is cooled, it is crushed and ground to obtain a calcium stannate ceramic precursor. The conversion rate of Sn was 99.4%.

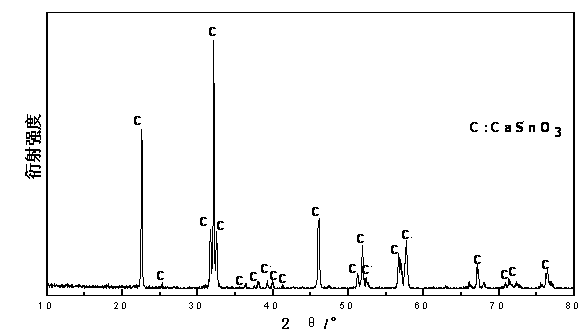

[0039] The XRD analysis of the sample obtained under the experimental conditions is shown in the appendix figure 2 , from attached figure 2 It can be seen that all the diffraction peaks correspond to calcium stanna...

Embodiment 2

[0041] Industrial grade tin dioxide (SnO 2 content of 97%) and calcium oxide (CaO content of 98%) as raw materials. Mix the finely ground tin dioxide and calcium oxide in a molar ratio of 1:1.05, add 1% bentonite and 15% water, and mix evenly; then use a double-roller briquetting machine to briquette the mixture and dry it. Finally, put it into a simulated annular rotary hearth furnace device for heating and roasting, the roasting temperature is 800 °C, the roasting time is 45 min, and the roasting atmosphere is composed of CO and CO 2 The composition of the mixed gas, where the volume concentration of CO [CO / (CO+CO 2 )] is 10%. After the calcined mass is cooled, it is crushed and ground to obtain a calcium stannate ceramic precursor. The conversion rate of Sn was 99.2%.

Embodiment 3

[0043] Industrial grade tin dioxide (SnO 2 content of 97%) and calcium carbonate (CaCO 3 Content is 98%) as raw material. Mix the finely ground tin dioxide and calcium oxide in a molar ratio of 1:1.05, add 2% slaked lime and 13% water, and mix evenly; then use a double-roller briquetting machine to briquette the mixture and dry it. Finally, put it into a simulated tunnel kiln device for heating and roasting, the roasting temperature is 1000 ° C, the roasting time is 15 min, and the roasting atmosphere is composed of CO and CO 2 The composition of the mixed gas, where the volume concentration of CO [CO / (CO+CO 2 )] was 17%. After the calcined mass is cooled, it is crushed and ground to obtain a calcium stannate ceramic precursor. The conversion rate of Sn was 99.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com