Automobile steering knuckle and manufacturing method thereof

A technology for steering knuckles and automobiles, which is applied to steering mechanisms, steering rods, vehicle components, etc. It can solve the problems of non-adjustable distance, difficult installation, and increased installation difficulty, so as to improve safety, facilitate use, facilitate installation and fixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

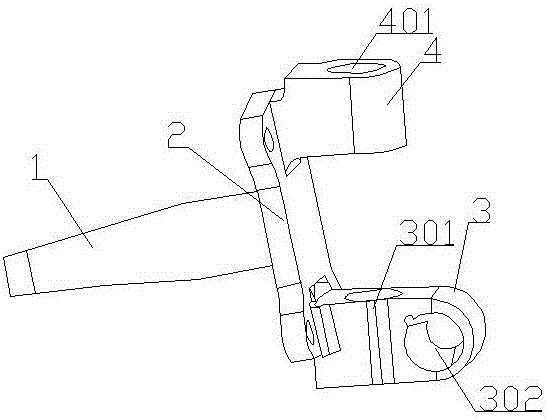

[0035] A steering knuckle for automobiles, which includes a fixed plate 2 connected to a rotating shaft 1 on one side and a first bush 3 and a second bush 4 arranged on the other side of the fixed plate 2, and the first bush 3 There is a kingpin hole 301 and a steering arm support hole 302 perpendicular to the kingpin hole 301, and the second bushing 4 is provided with a fixing hole 401 used in conjunction with the kingpin hole 301 of the first bushing 3 .

[0036] In some embodiments, the fixed plate 2 includes a base plate and two insert plates arranged symmetrically on both sides of the base plate, and the first sleeve 3 and the second sleeve 4 are respectively arranged on two sides of the base plate. board.

[0037] In some more specific embodiments, a cavity is opened on the base plate, and the plug-in board can reciprocate in the cavity, so that the distance between the two plug-in boards can be adjusted.

[0038] In some more specific embodiments, the inserting board ...

Embodiment 2

[0051] A steering knuckle for automobiles, which includes a fixed plate 2 connected to a rotating shaft 1 on one side and a first bush 3 and a second bush 4 arranged on the other side of the fixed plate 2, and the first bush 3 There is a kingpin hole 301 and a steering arm support hole 302 perpendicular to the kingpin hole 301, and the second bushing 4 is provided with a fixing hole 401 used in conjunction with the kingpin hole 301 of the first bushing 3 .

[0052]In some embodiments, the fixed plate 2 includes a base plate and two insert plates arranged symmetrically on both sides of the base plate, and the first sleeve 3 and the second sleeve 4 are respectively arranged on two sides of the base plate. board.

[0053] In some more specific embodiments, a cavity is opened on the base plate, and the plug-in board can reciprocate in the cavity, so that the distance between the two plug-in boards can be adjusted.

[0054] In some more specific embodiments, the inserting board h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com