Patents

Literature

47results about How to "Improve ammonia removal efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

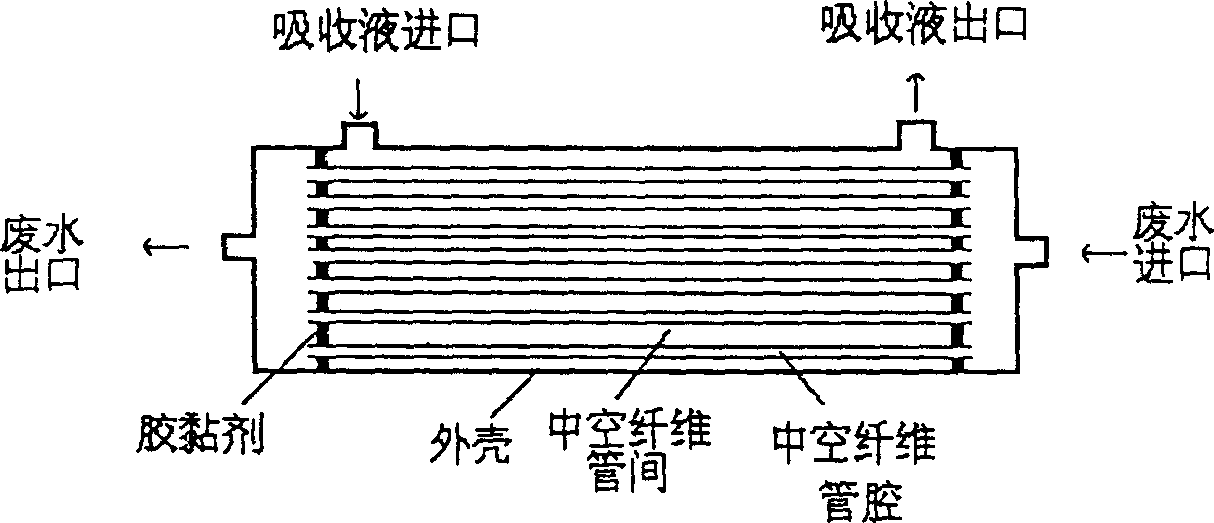

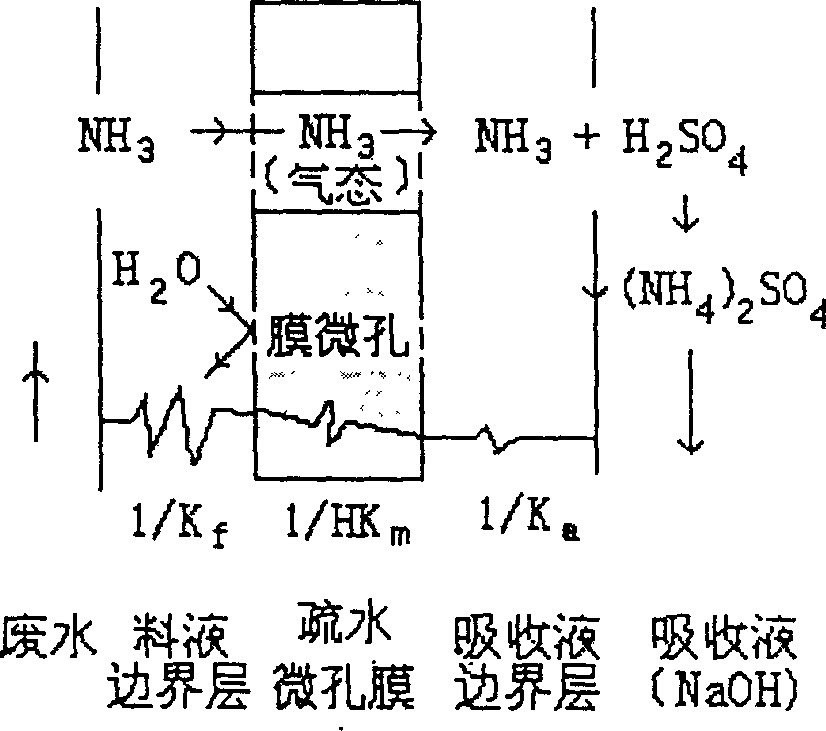

Technology for treating high concentration ammonia nitrogen waste water using membrane based absorption method

InactiveCN1546393ALow costPrevent floodingSemi-permeable membranesWater/sewage treatment by neutralisationContactorChemistry

A process for reclaiming high concentration ammonia nitrogen waste water by film based absorption wherein a hollow fiber film contactor is employed, the high concentration ammonia nitrogen waste water flows through the tube pass of the contactor, i.e. the lumen of hollow fiber, while the absorption solution H2SO4 flows through shell pass. When applied to treatment for high concentration residual ammonia in coking plant, the invention achieves the effect of one time discharge standard meeting, with the ammonia clearance reaching 99.7% in the water outlet, and the ammonia recovery ratio in the absorbing agent reaching 99.5%.

Owner:JIANGNAN UNIV

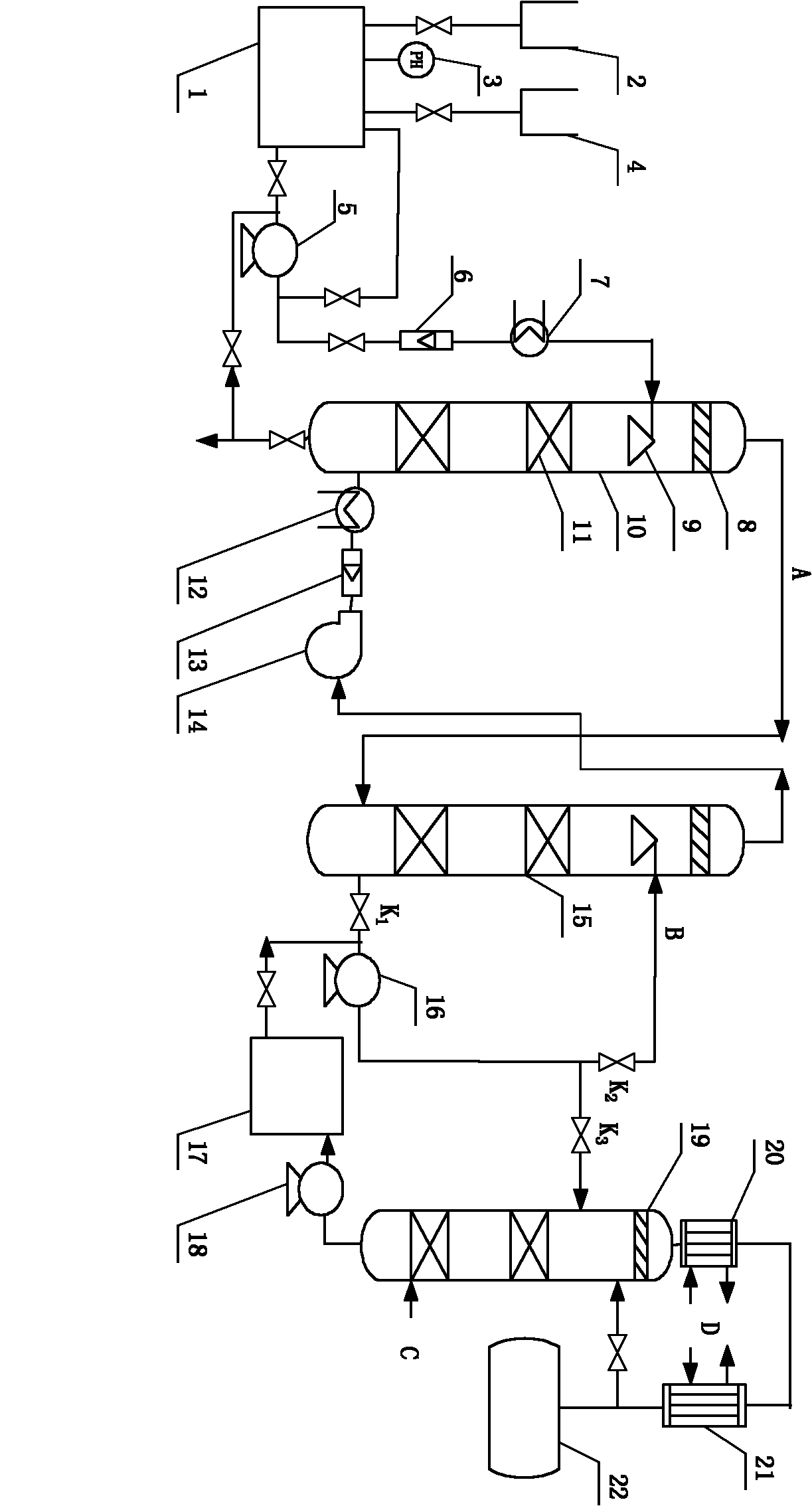

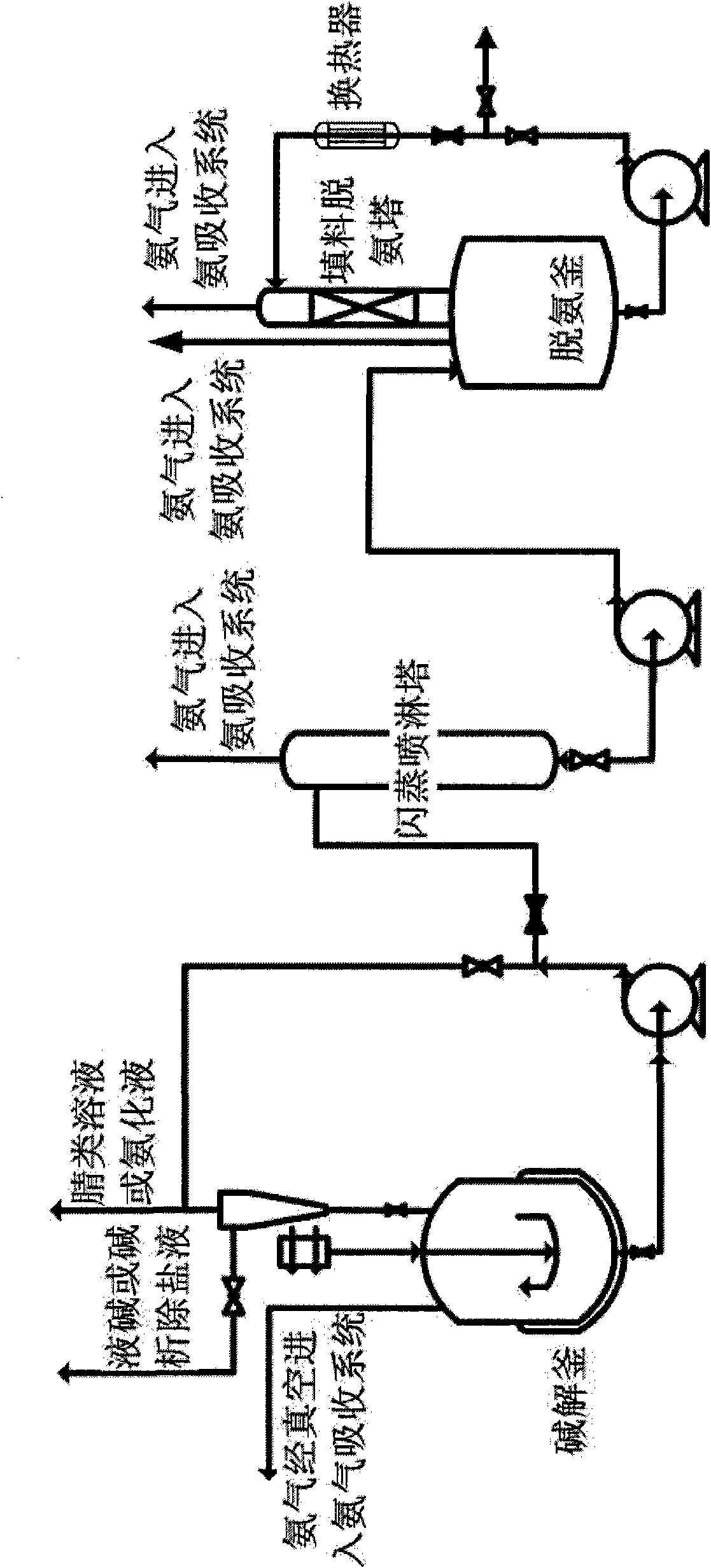

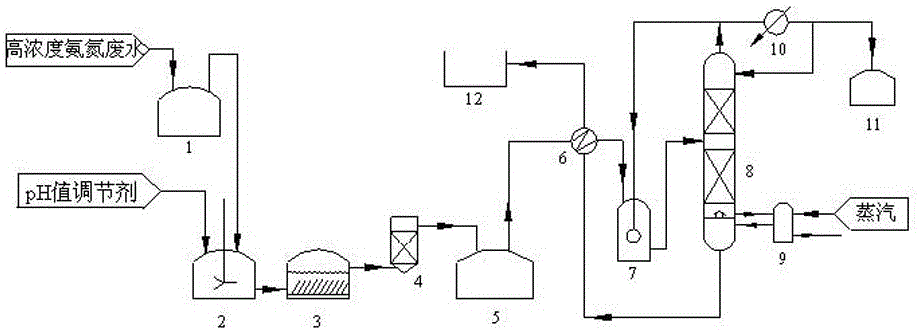

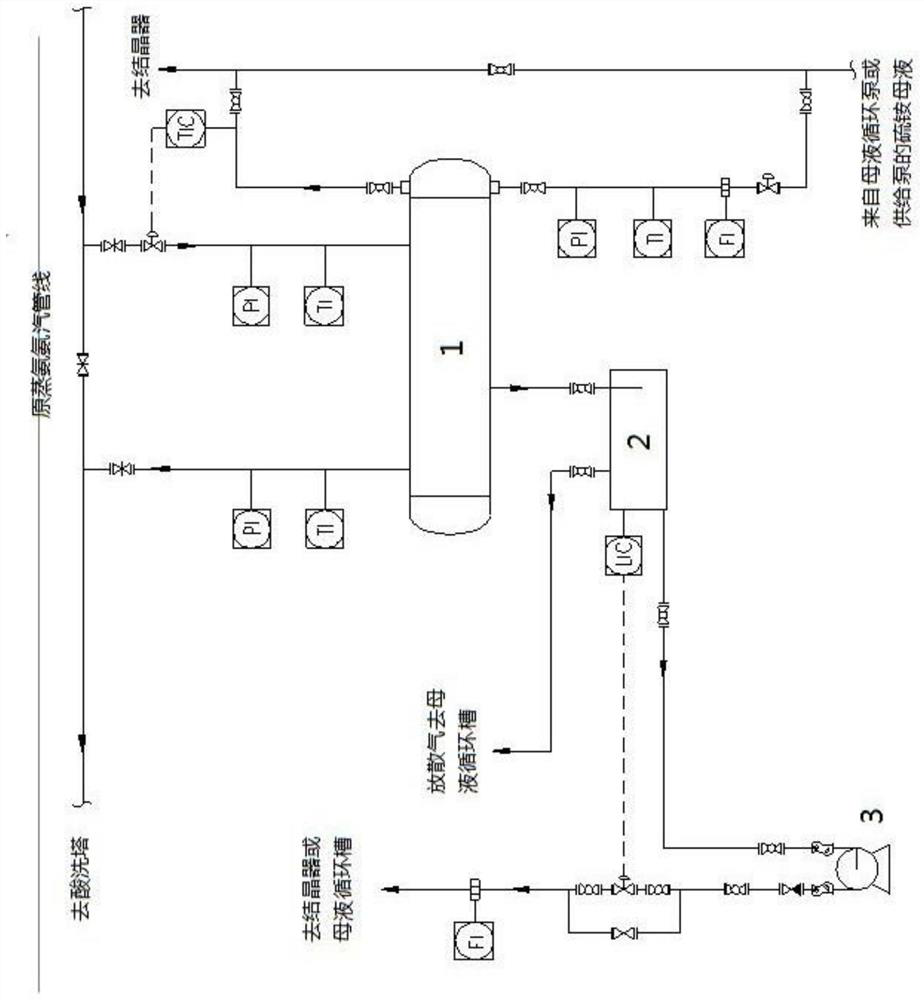

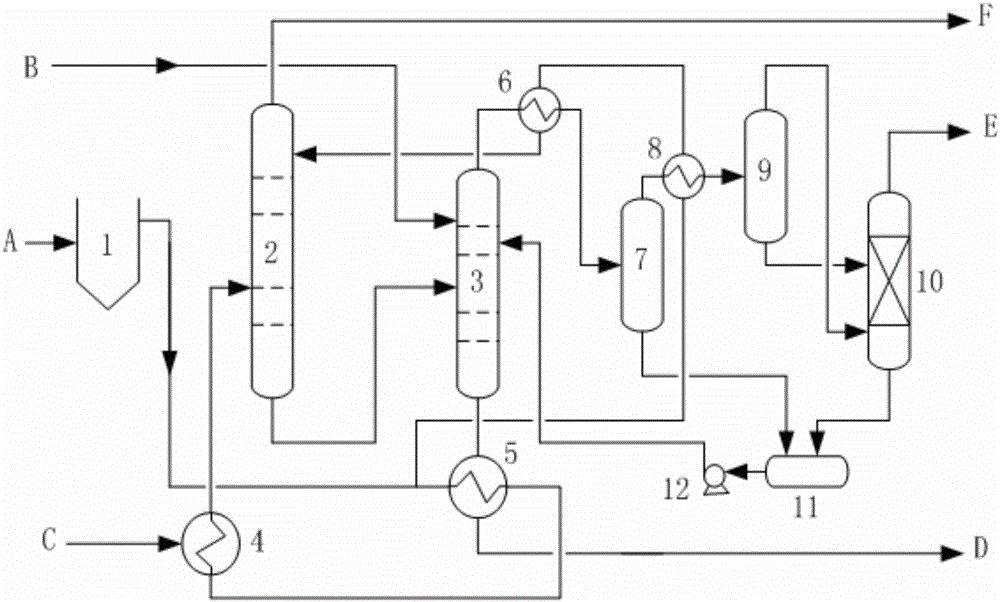

Closed-loop processing integrated process for high-efficiency air stripping and tail-gas ammonia recycling of ammonia-nitrogen wastewater

ActiveCN102060406AImprove ammonia removal efficiencyReduce the gas-liquid volume ratioChemical industryMultistage water/sewage treatmentExhaust gasProcess engineering

The invention relates to a closed-loop processing integrated process for the high-efficiency air stripping and the tail-gas ammonia recycling of ammonia-nitrogen wastewater, which is characterized in that: by selecting the types of fillers, tower internals and the like of an ammonia-nitrogen air-stripping tower and strengthening a gas-liquid mass transferring process, the ammonia removing efficiency is improved, and meanwhile, the gas-liquid volume ratio is reduced, thereby the energy consumption is markedly reduced; the invention provides a renewable ammonia-absorbing solution which can be used for efficiently absorbing the ammonia in air-stripping gas, and the ammonia is regenerated and desorbed to obtain strong ammonia water with the concentration of 10-25wt%, therefore, the high-efficiency recovery and the recycling of the ammonia in the air-stripping gas is realized, and the absorbing solution is recycled after being regenerated; the purified gas after absorption is used as the air-stripping gas for closed-loop circulating by adopting a closed-loop circulating technology, thereby the reaction heat in the absorbing process is effectively recovered, the energy consumption is further reduced, and meanwhile, the secondary pollution is eliminated; and the ammonia-removing and recycling processes of the wastewater are developed into a set of modularized process technologies by applying an integrated technology, thereby the technical requirements of industrial enterprises on processing the ammonia-nitrogen wastewater with different concentrations are satisfied.

Owner:NANJING UNIV OF TECH

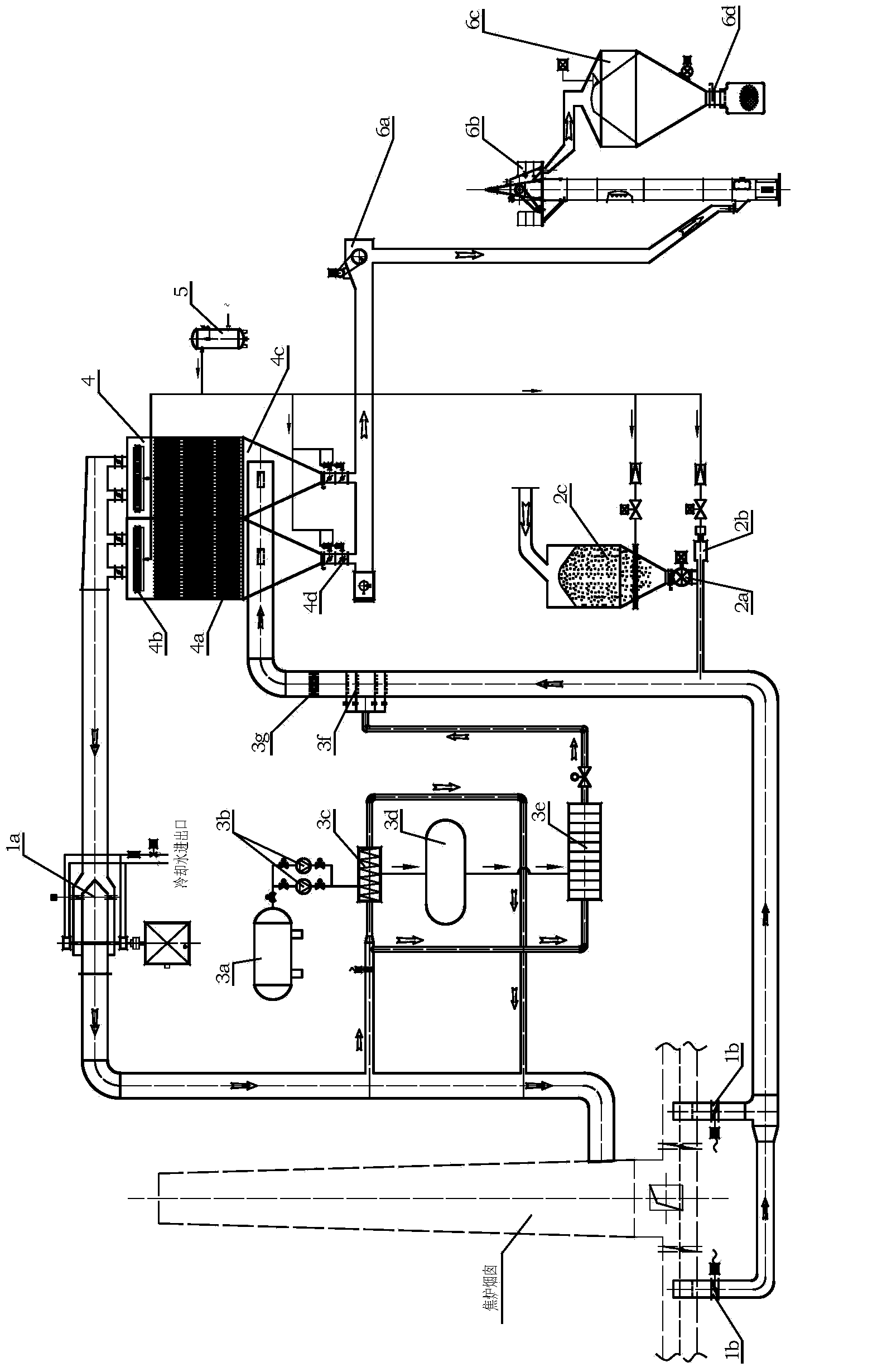

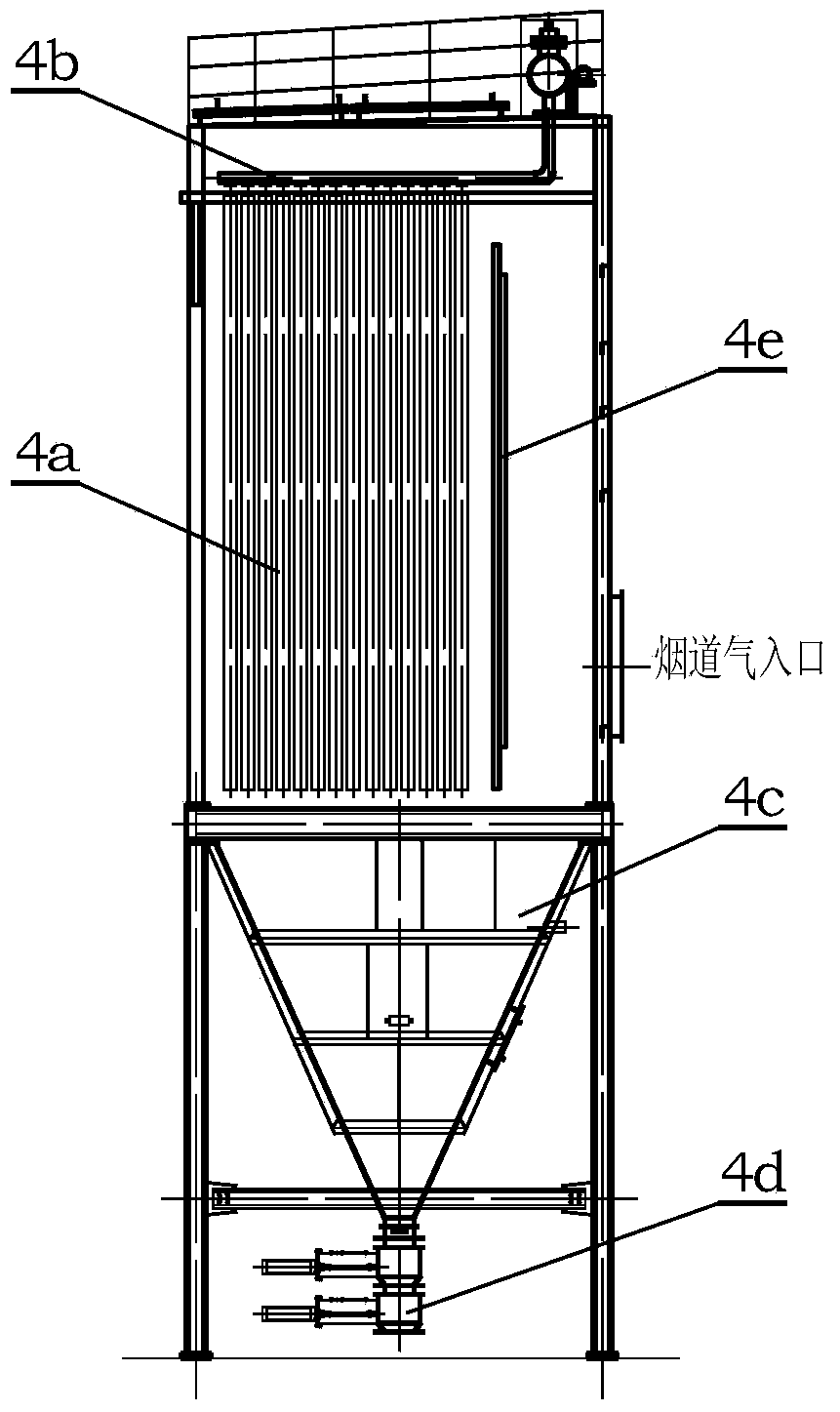

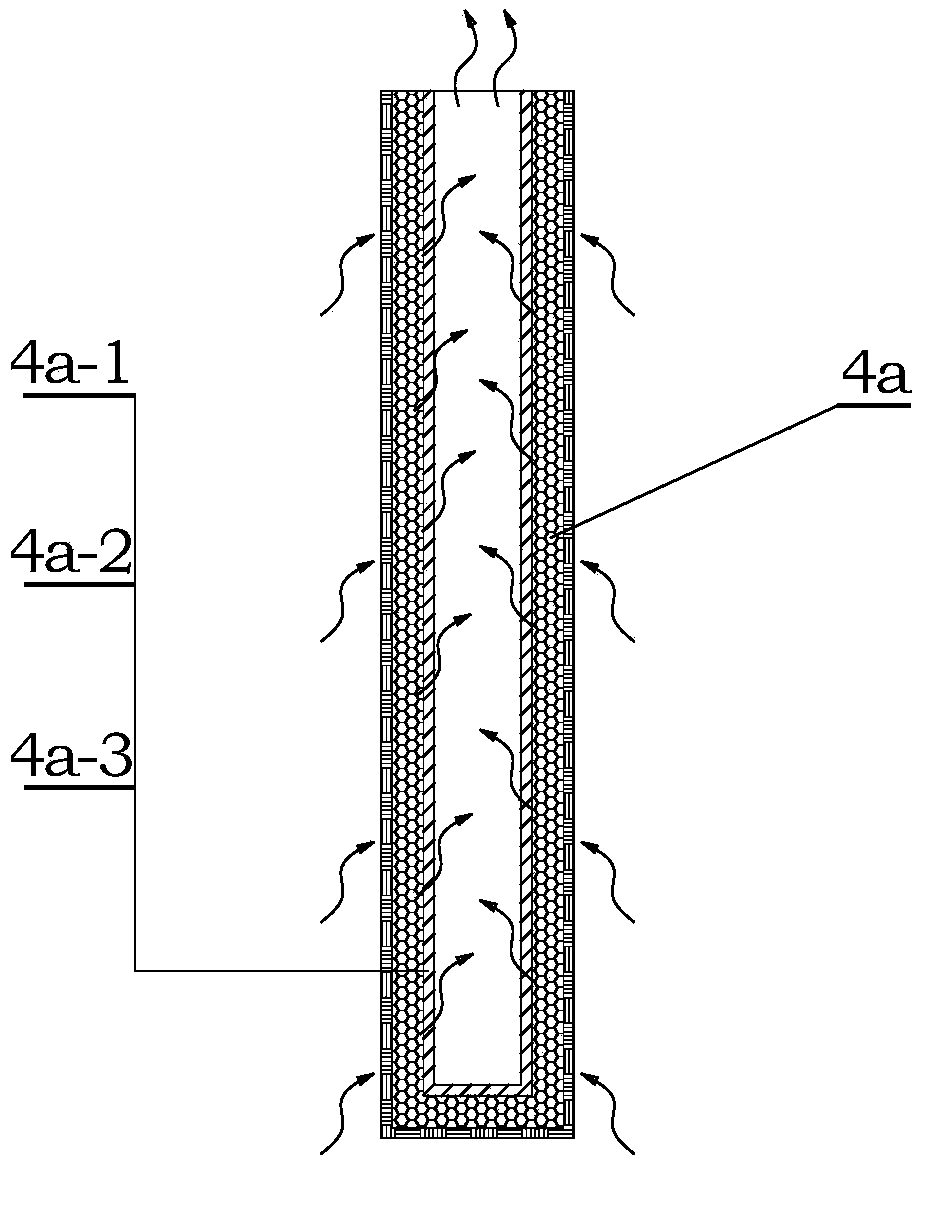

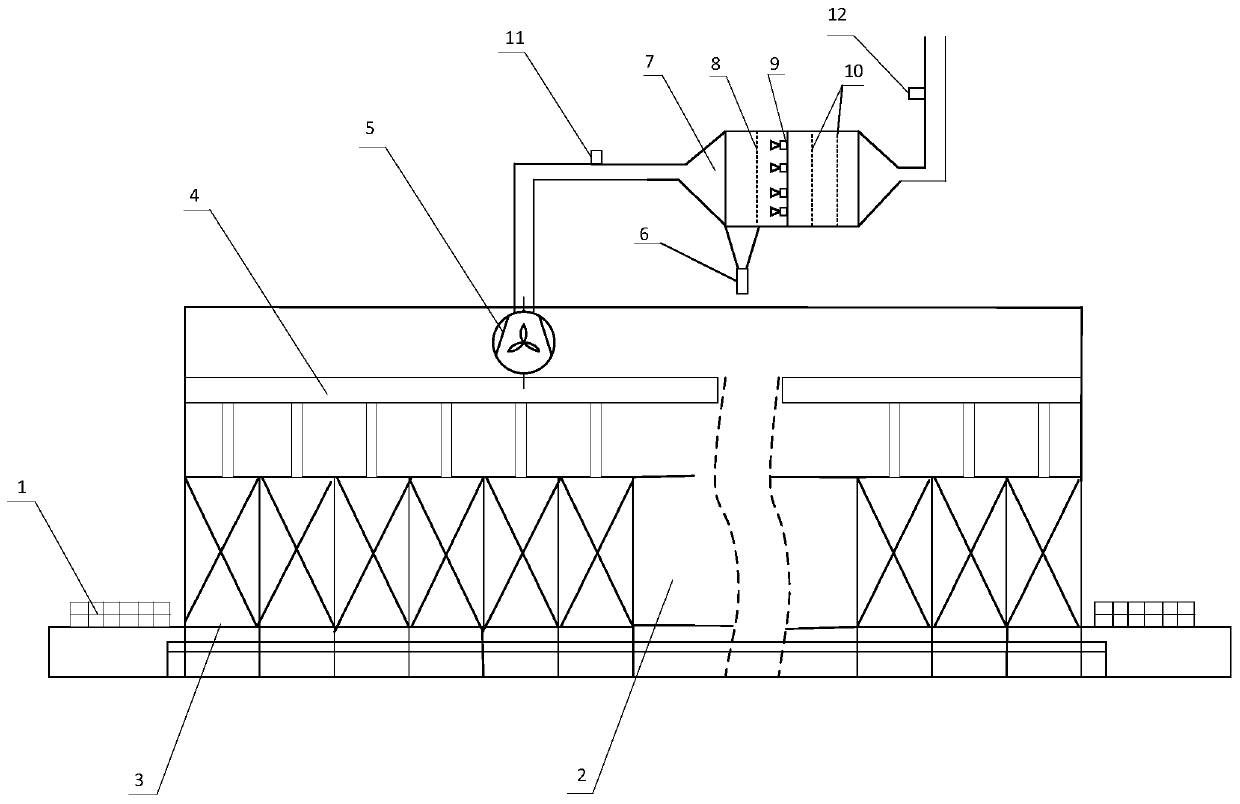

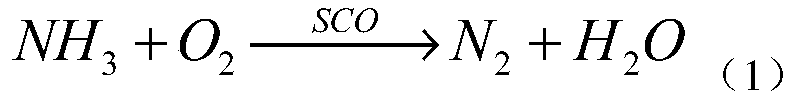

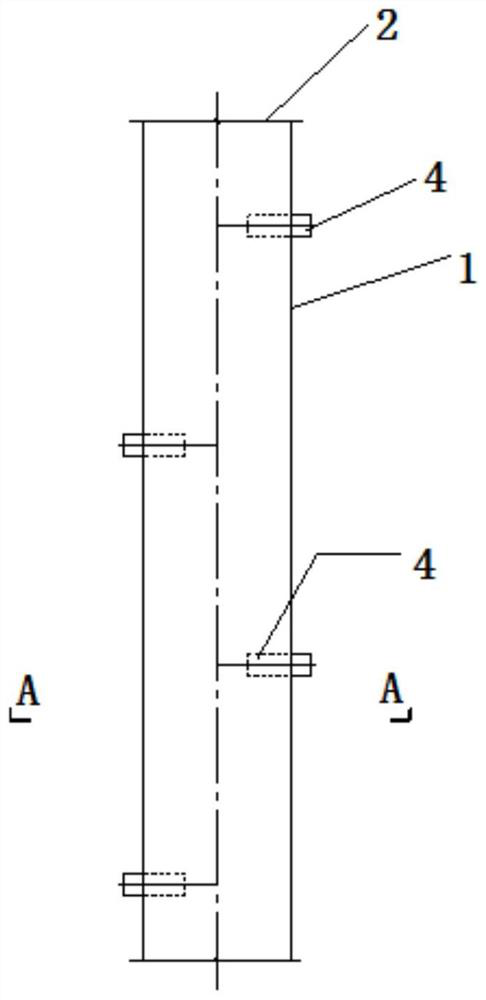

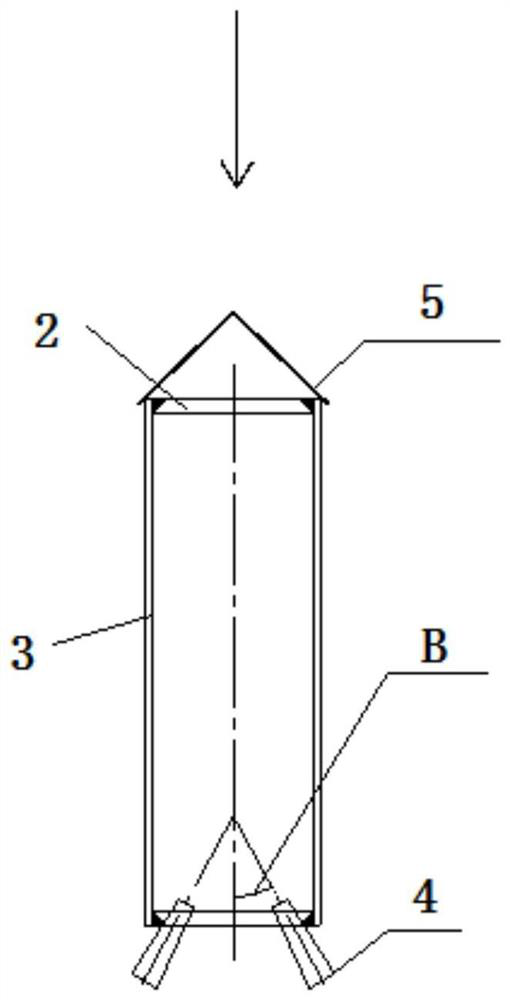

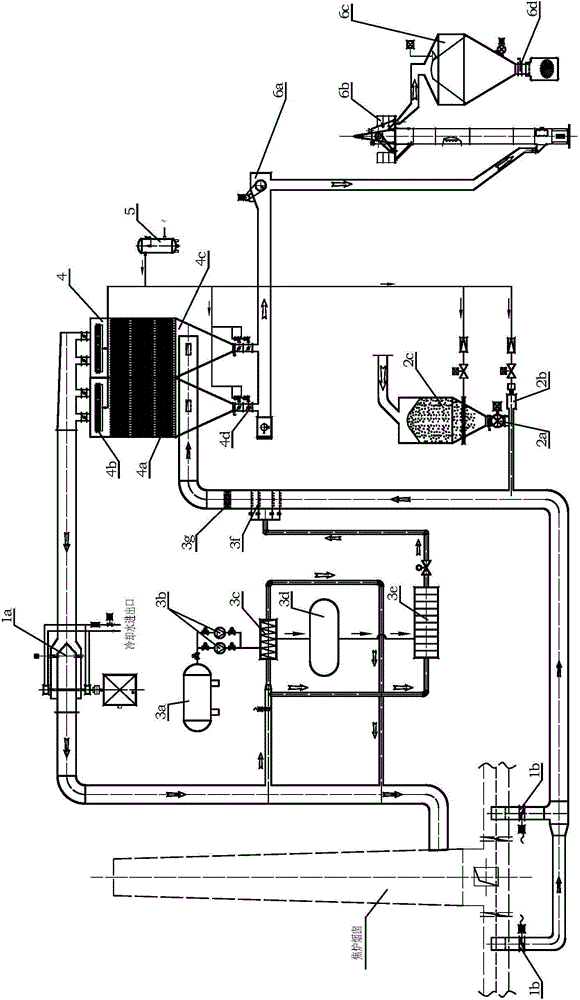

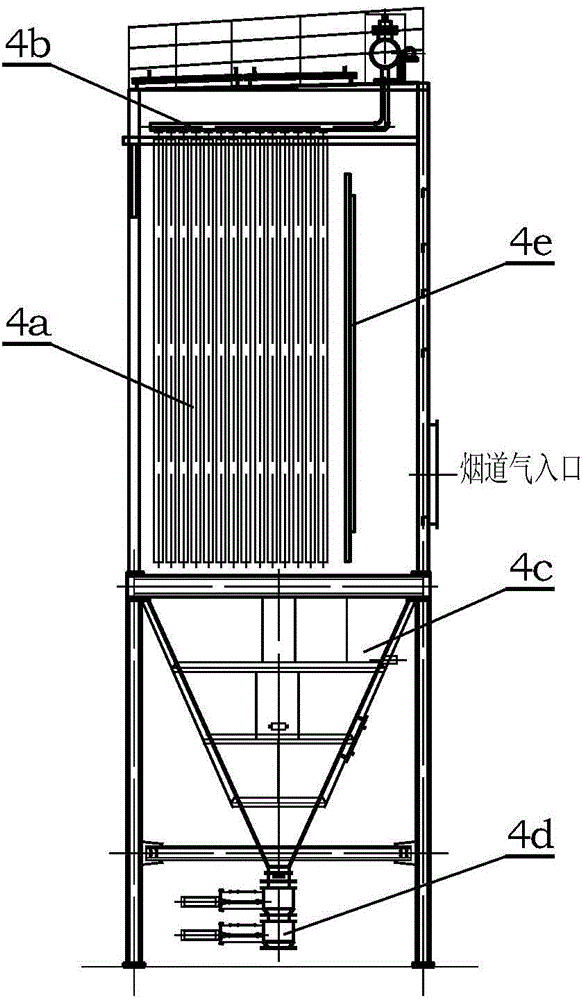

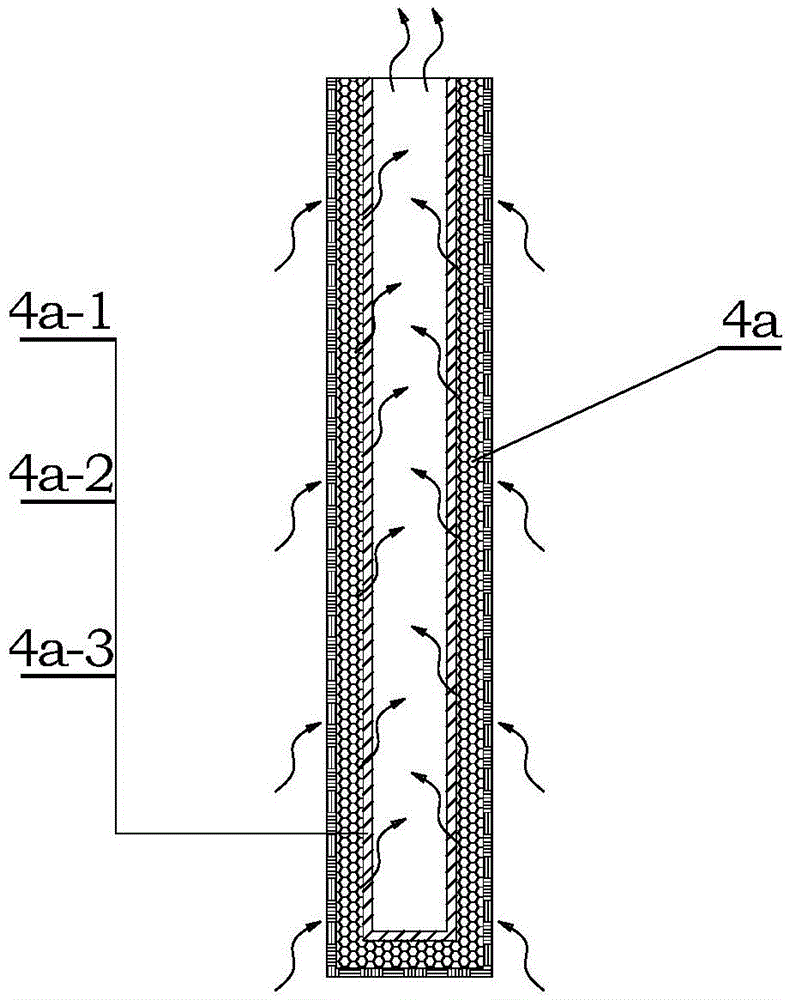

Integrated low-temperature flue gas desulfurization, denitration and ammonia removal process

ActiveCN103816780AImprove dust filtration efficiencyImprove efficiencyDispersed particle separationEvaporationEmission standard

The invention relates to an integrated low-temperature flue gas desulfurization, denitration and ammonia removal process suitable for the desulphurization and the denitration of coke oven flue waste gas of which flue gas temperature is greater than 180 DEG C and the content of SO2 is less than 150 mg / Nm3. According to the process, dry desulphurization is performed before denitration according to a fluidized principle, ammonia gas produced by evaporating residual ammonia water at an ammonia evaporation workshop section in a coking plant is used as a reducing agent, a cloth bag combining with an ammonia removal catalyst composite structure is used as a dust removing and denitration manner, and during efficient desulphurization and denitration, an escape amount of ammonia is controlled to be lower than a national emission standard value. Compared with the prior art, the process has the benefits that 1), the integrated desulphurization, denitration and ammonia removal efficiency is high; 2) the denitration manner is unique, and the structural form of equipment is advanced; 3) ash removal is simple; 4) the energy is saved, and the operating cost and the once investment are reduced; 5) residual ammonia water in a coal gas purification process is fully recycled; 6) the residual heat is fully recycled.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Preparation method of plant extracting solution deodorant

The invention discloses a preparation method of a plant extracting solution deodorant. The deodorant uses Chinese herbal medicine as raw materials, a volatile oil extractor is adopted for extraction to obtain water extracting solution and volatile oil, the water extracting solution is subjected to separation and refining processes to obtain water extracts, then, the water extracts, the volatile oil, de-ionized water and essence are mixed for emulsification, and finally, the plant extracting solution deodorant disclosed by the invention is prepared through filtering. The plant extracting solution deodorant disclosed by the invention has the characteristics that the use is safe and convenient, the environmental-friendly effect, no toxicity and no harm are realized, through field experiment detection in a garbage transfer station, the ammonia gas removal rate can reach about 63 percent, the odor concentration inside and outside the garbage transfer station after deodorization can be much lower than the national standard, the peripheral air quality and the work condition in the garbage transfer station are greatly improved, in addition, the use cost of the deodorant is very low, and the deodorant is suitable for being used for deodorization in the garbage transfer station of urban communities.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

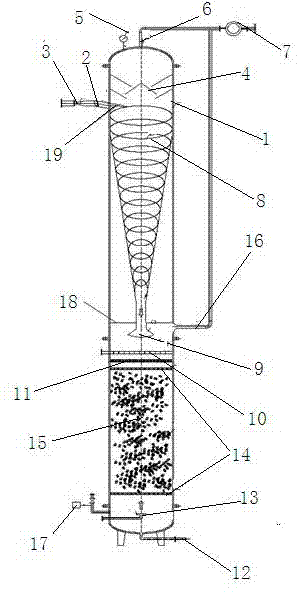

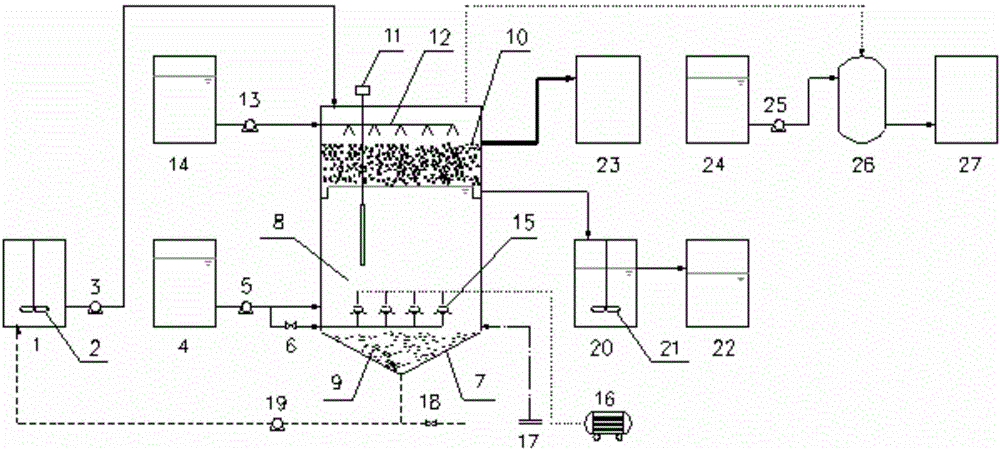

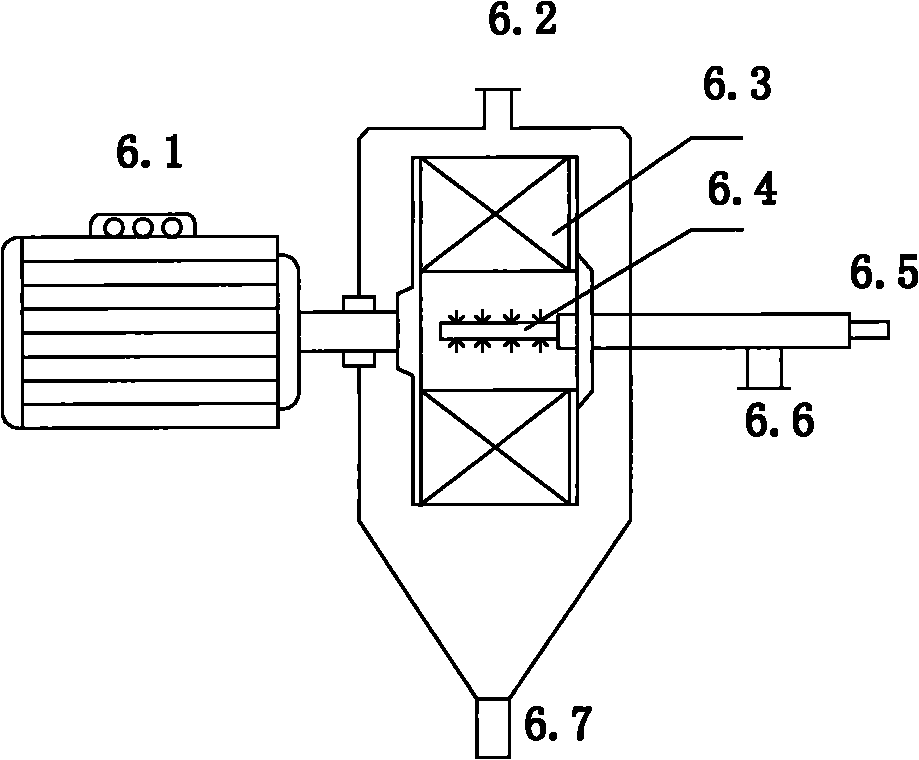

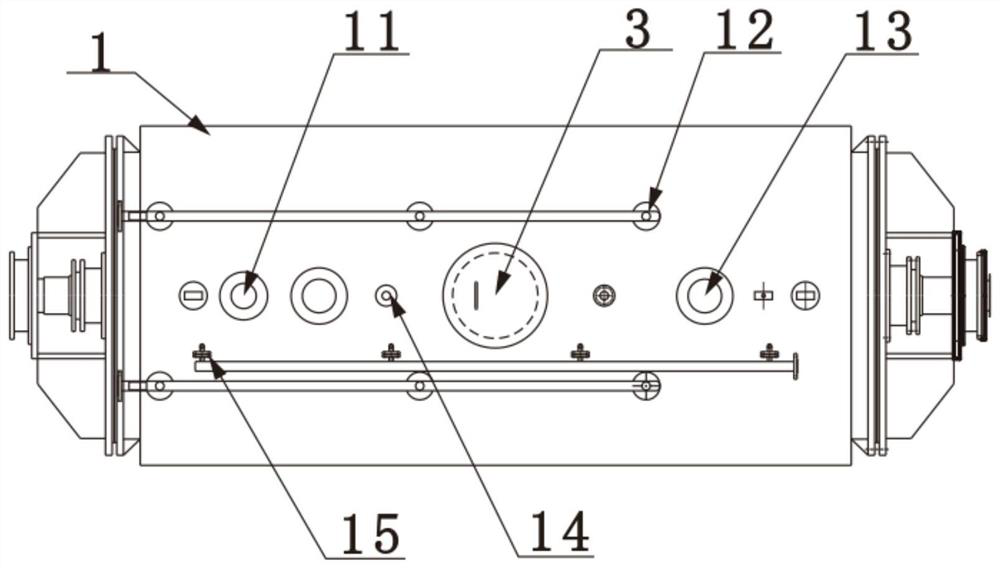

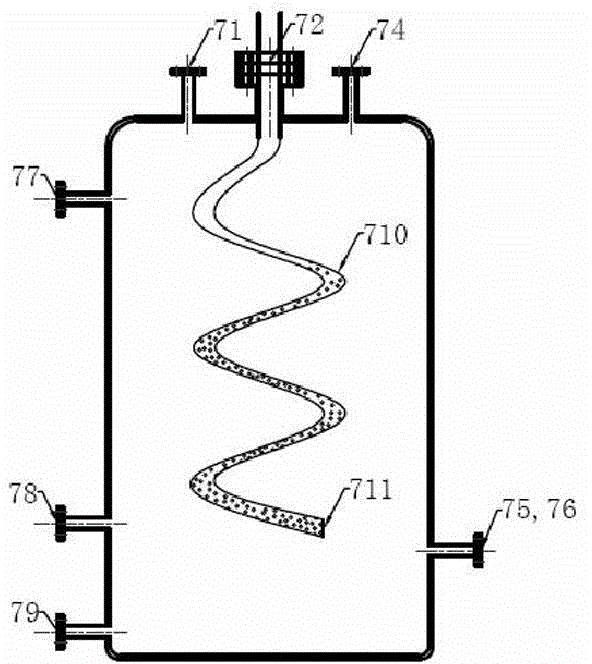

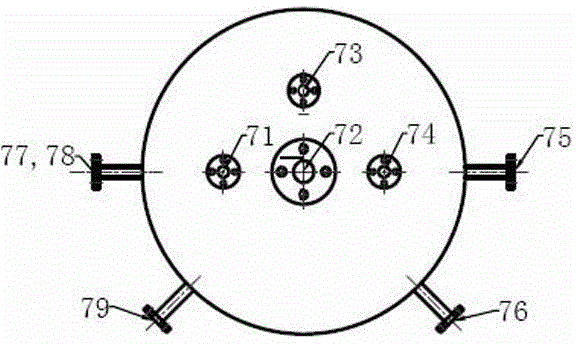

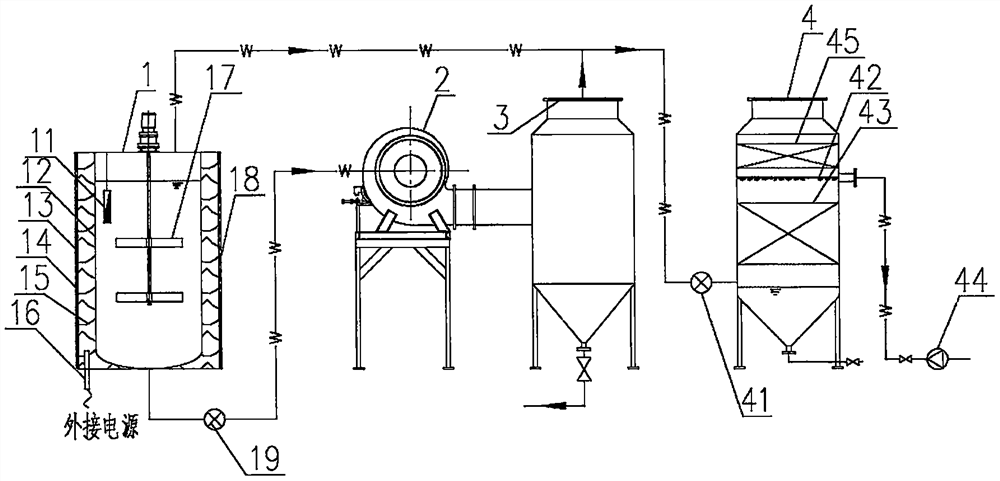

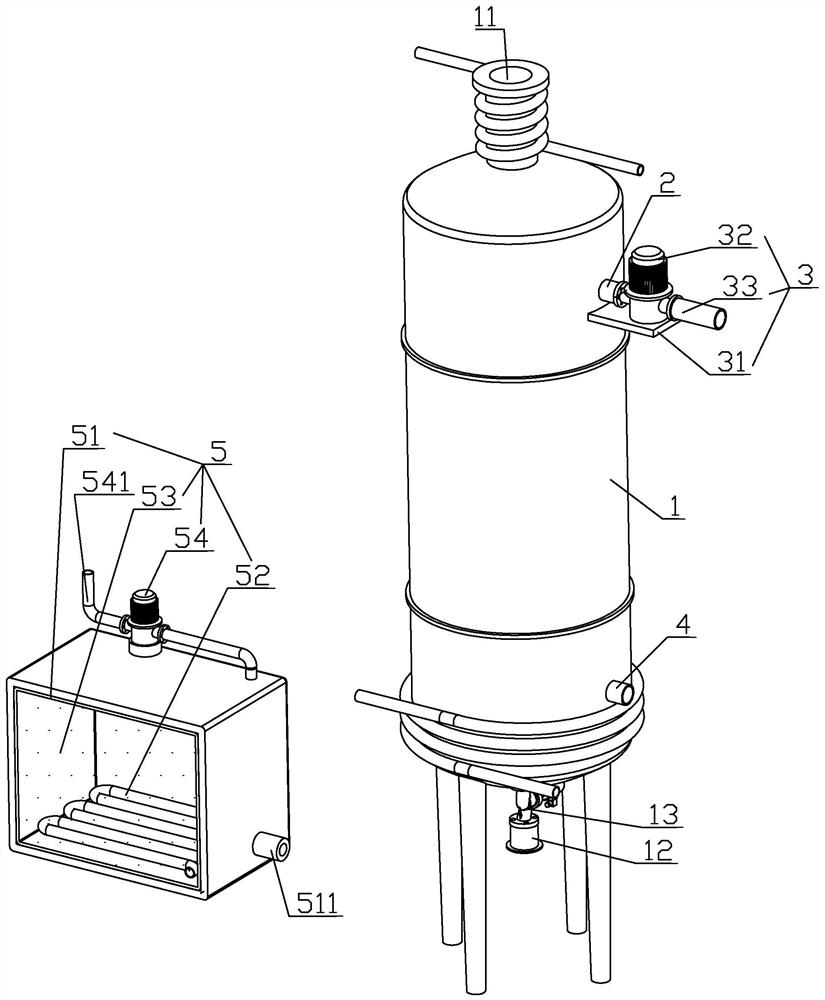

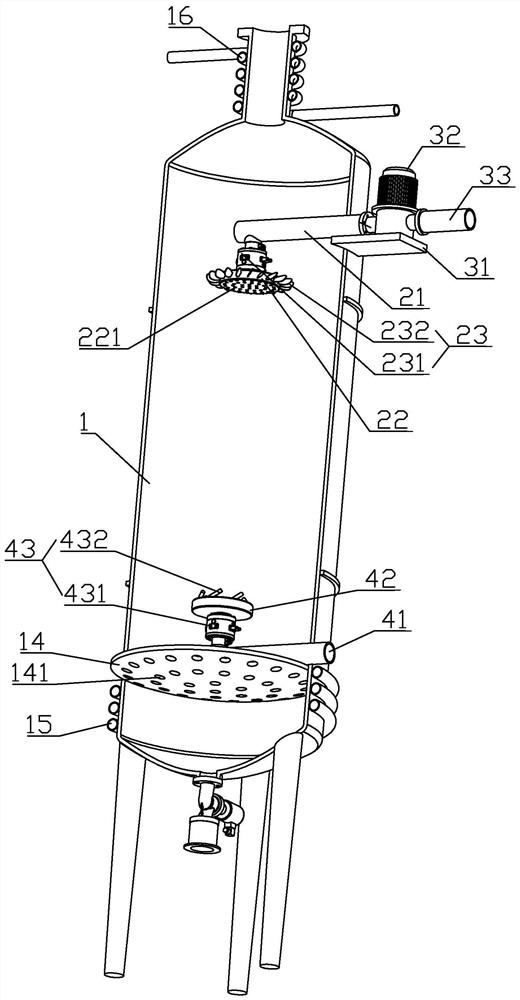

Cyclone stripping integration ammonia removal reaction tower

InactiveCN103043809AEfficient removal of ammoniaImprove ammonia removal efficiencyMultistage water/sewage treatmentAtmospheric sciencesMechanical engineering

The present invention relates to a cyclone stripping integration ammonia removal reaction tower. The reaction tower is a sealing tank of an overall structure, including an input device, a cyclone separation device, a stripping device, a detection device and an output device, wherein the cyclone separation device is disposed on the top of the tank, the stripping device is arranged below the tank, the cyclone separation device and the stripping device are divided by a baffle, and the bottom of the cyclone separation device is provided with a water distributor communicated with the stripping device. The invention employs the way of combining the cyclone separation and the stripping, provides an integration reactor which can remove ammonia efficiently, and has the characteristics of high ammonia removal efficiency, low energy consumption and simple operation.

Owner:NANJING RUNTRY WATER

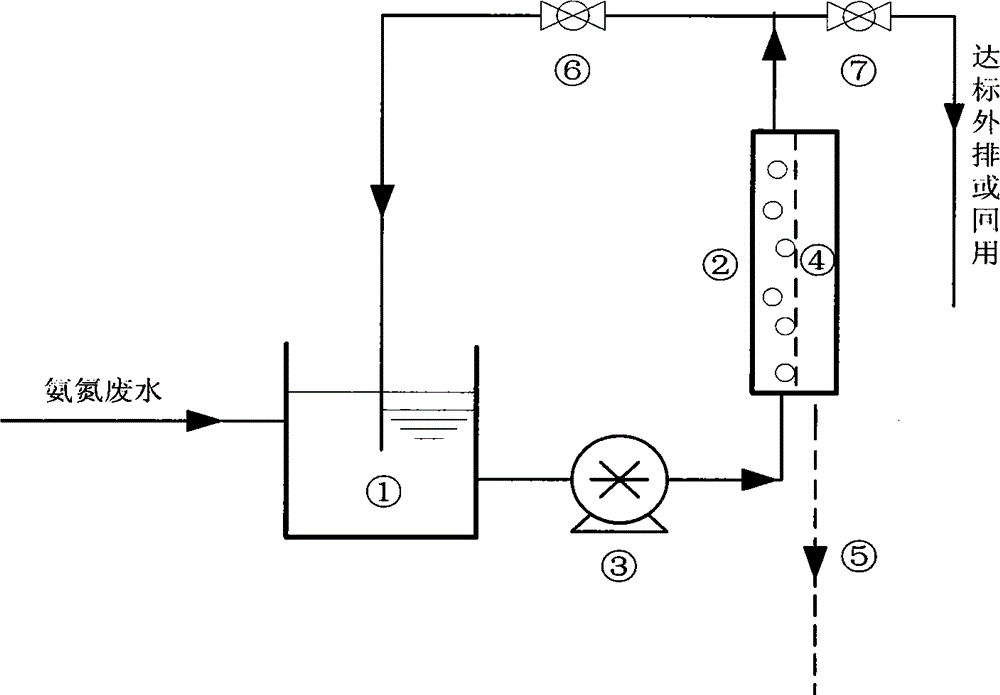

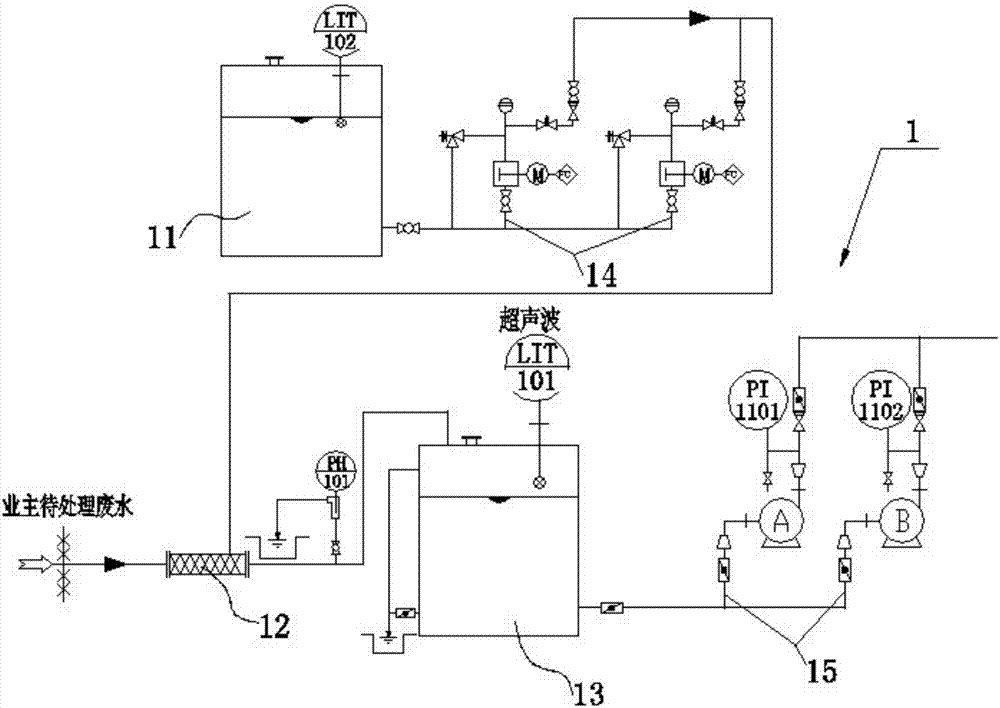

Method of electrolyzing wastewater containing ammonia nitrogen and apparatus therefor

ActiveCN101198551ASuppress generationPromote decompositionWater treatment parameter controlWater contaminantsPower flowChloride

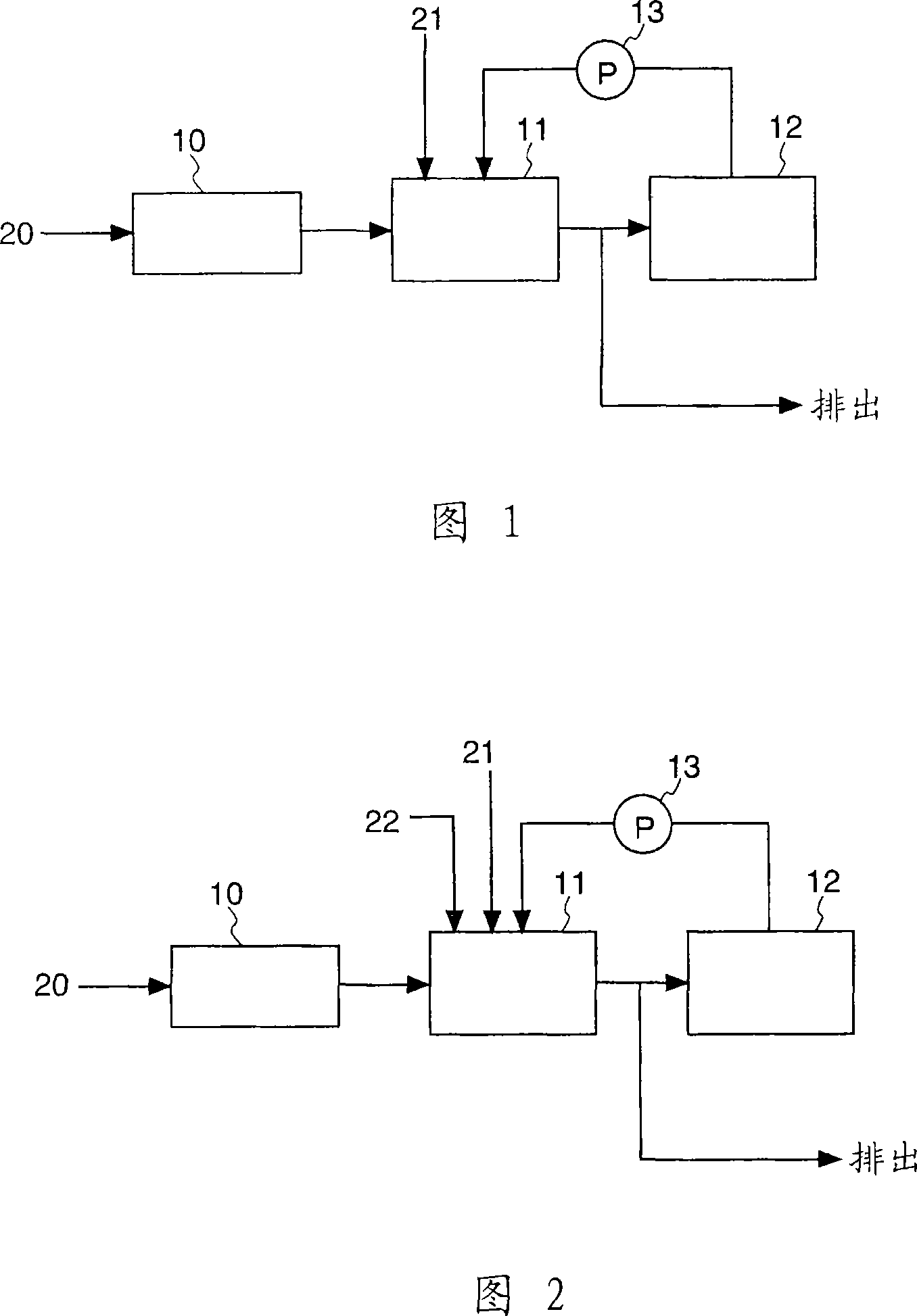

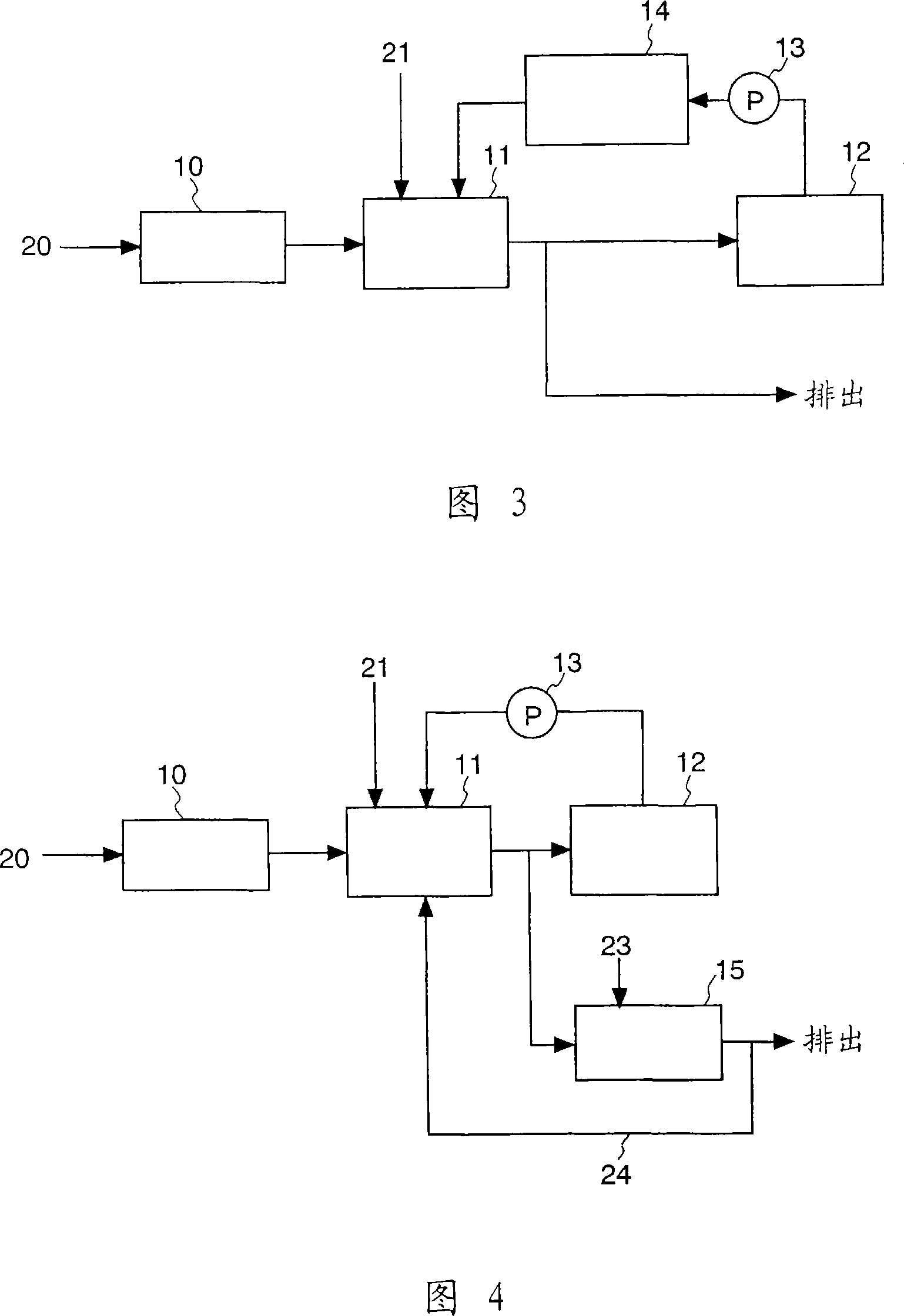

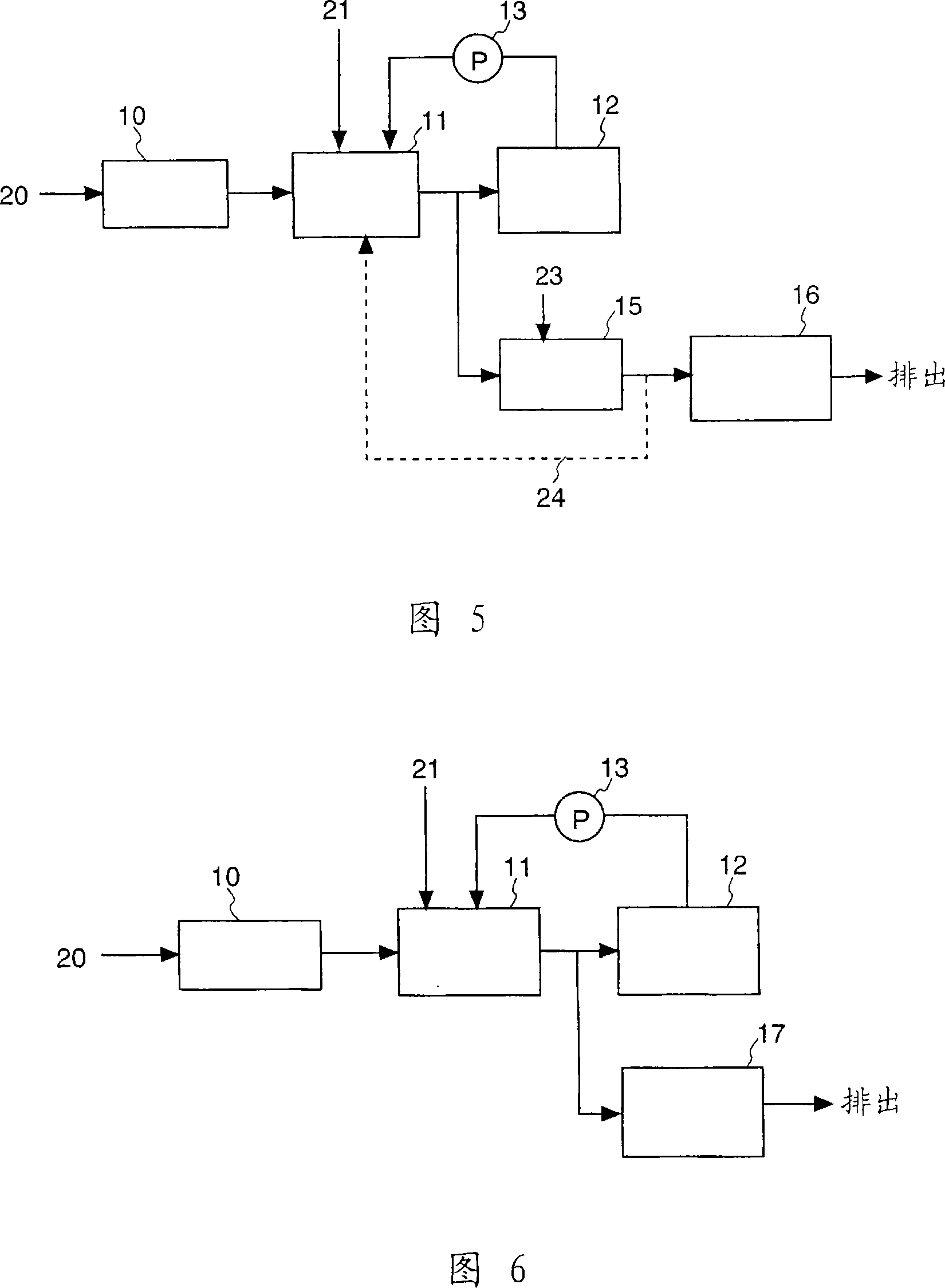

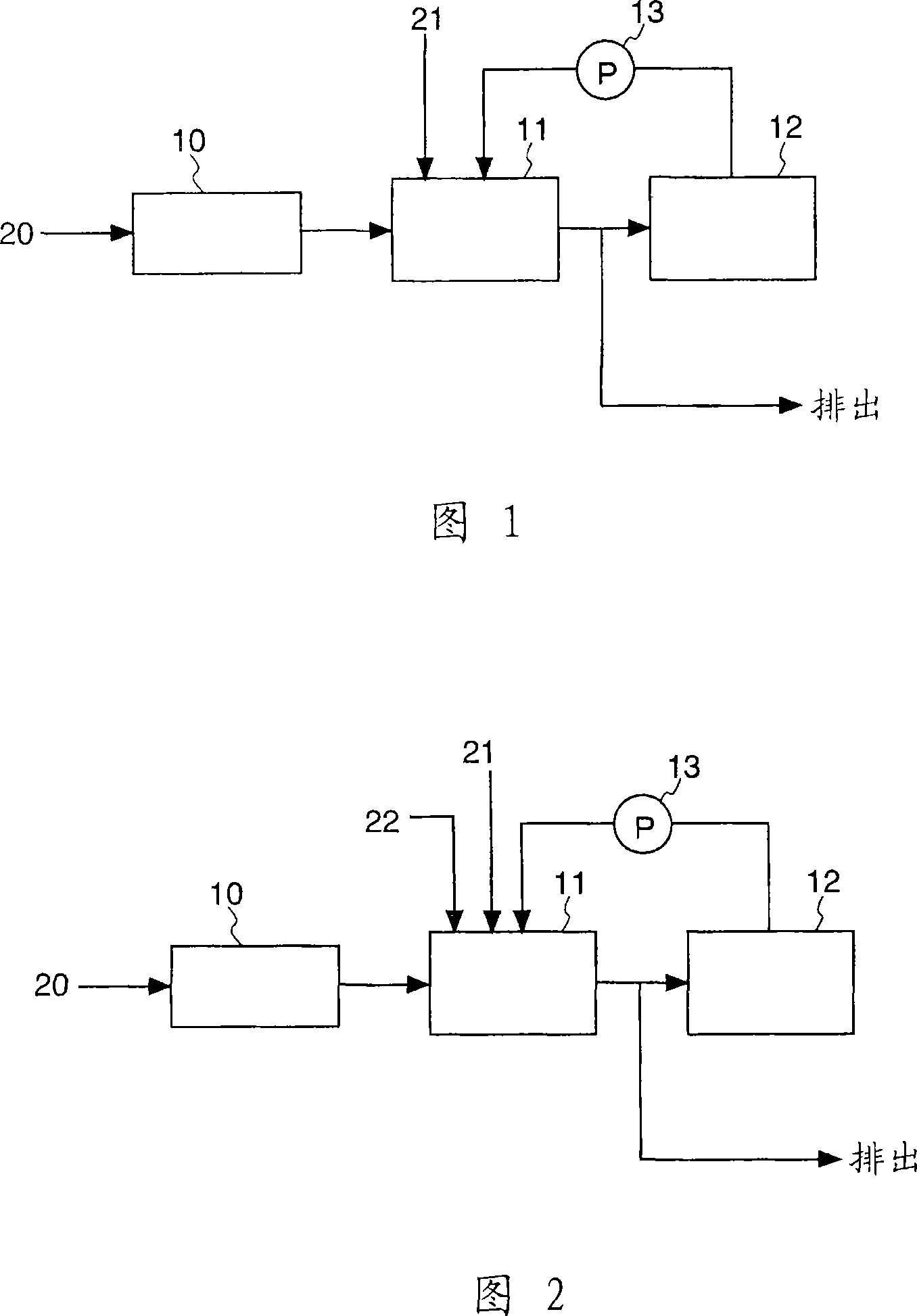

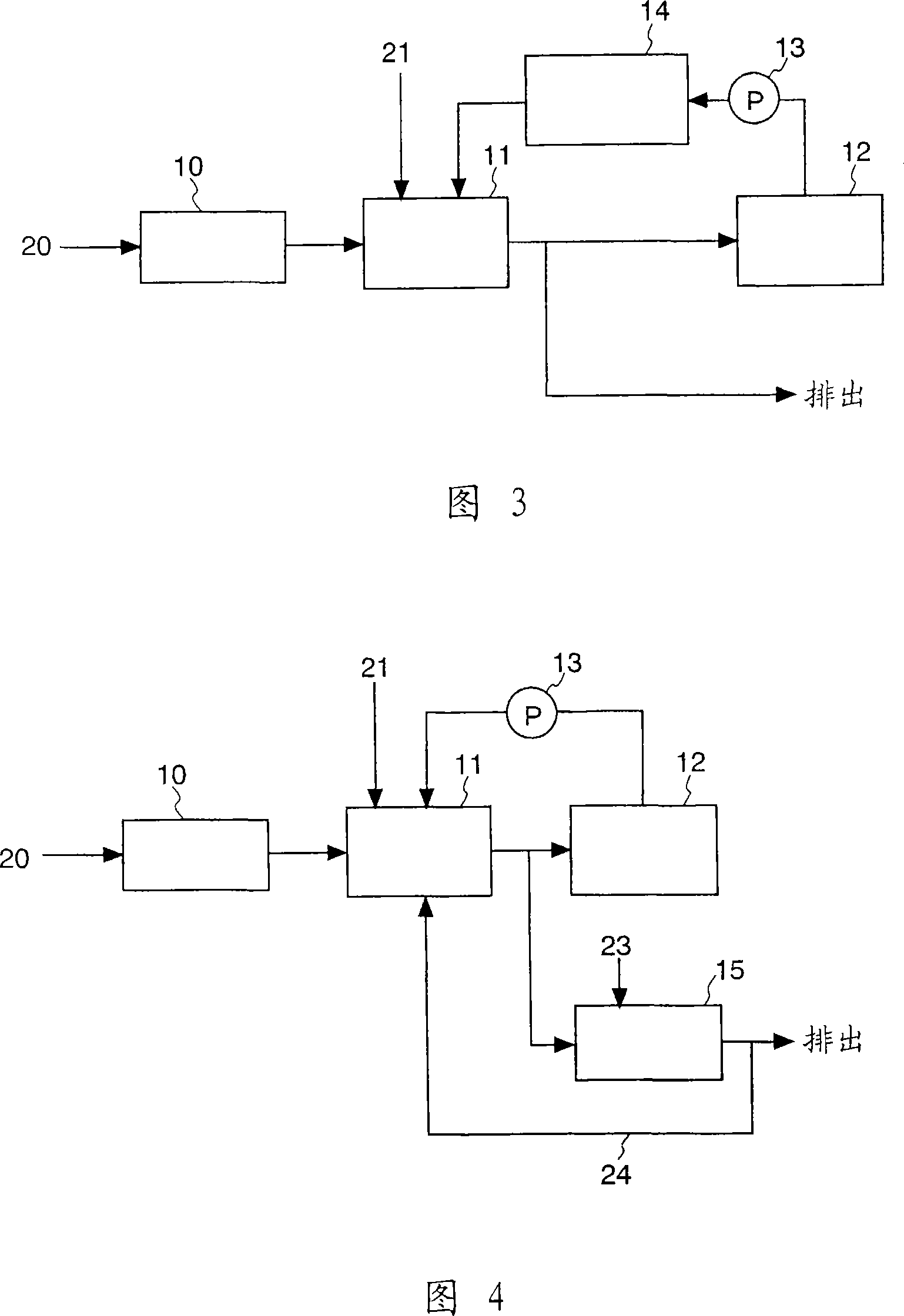

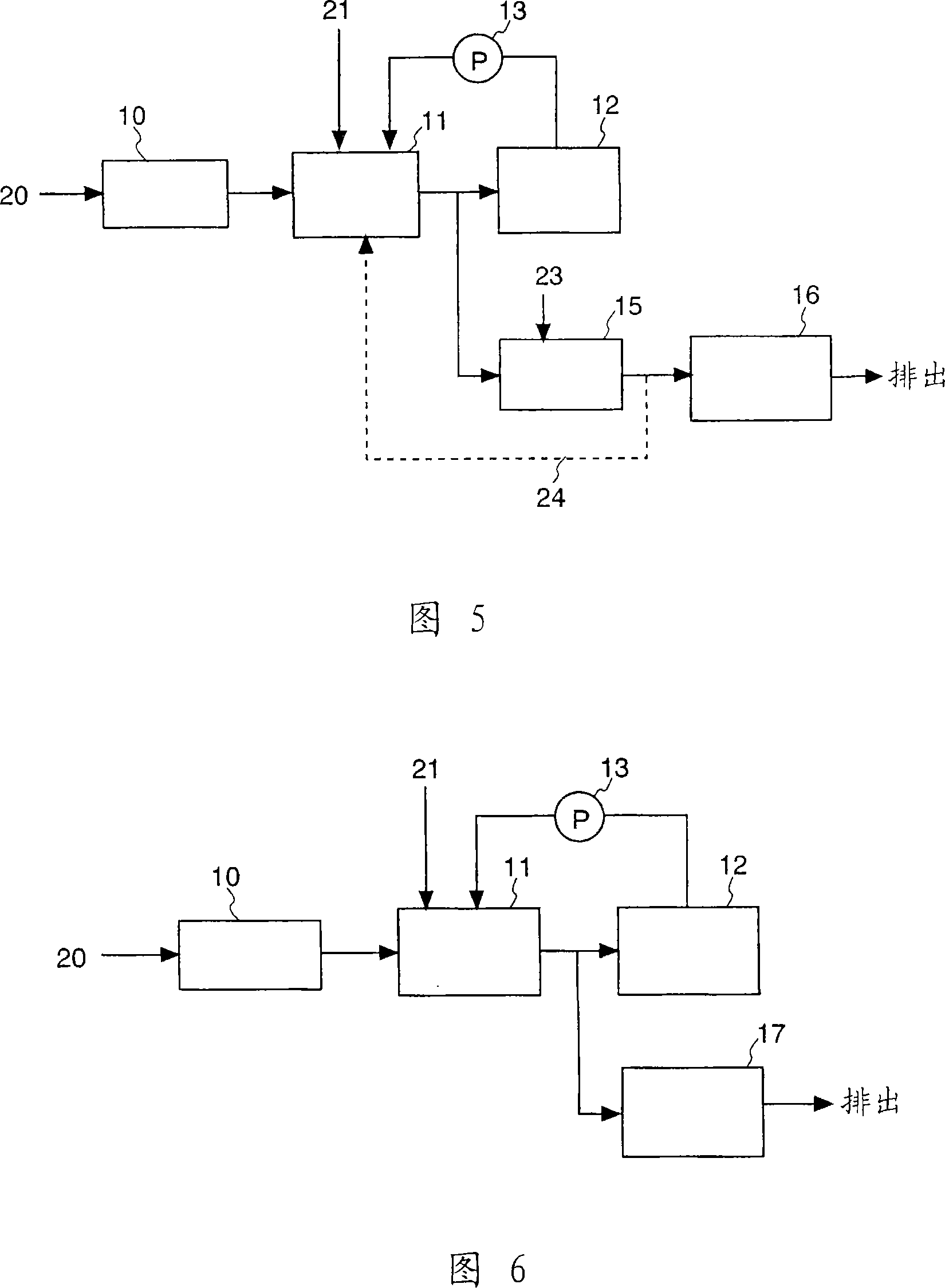

The object of the present invention is to provide an electrolytic treatment method and device for wastewater containing ammoniacal nitrogen, which can prevent the reduction of current efficiency and improve the decomposition efficiency of ammonia, and can safely and effectively treat all wastewater containing nitrogen . The electrolytic treatment device of the present invention is an electrolytic treatment device for wastewater containing ammoniacal nitrogen with the following parts: an adjustment tank (11) into which the wastewater containing ammoniacal nitrogen flows, and the electrolytic treatment is supplied by the adjustment tank under the condition of having chloride ions. The electrolytic cell (12) of the waste water (20), and the circulating pump (13) that makes the waste water circulate in the above-mentioned adjustment tank (11) and the above-mentioned electrolytic cell (12); wherein the above-mentioned electrolytic cell (12) has a pH value of 5 For electrolytic treatment of the above-mentioned waste water in the range above and less than 8, it is preferable to arrange a catalyst member formed of a metal material in the above-mentioned electrolytic cell (12) to promote the decomposition reaction of ammoniacal nitrogen.

Owner:MITSUBISHI HEAVY IND ENVIRONMENTAL & CHEM ENG CO LTD

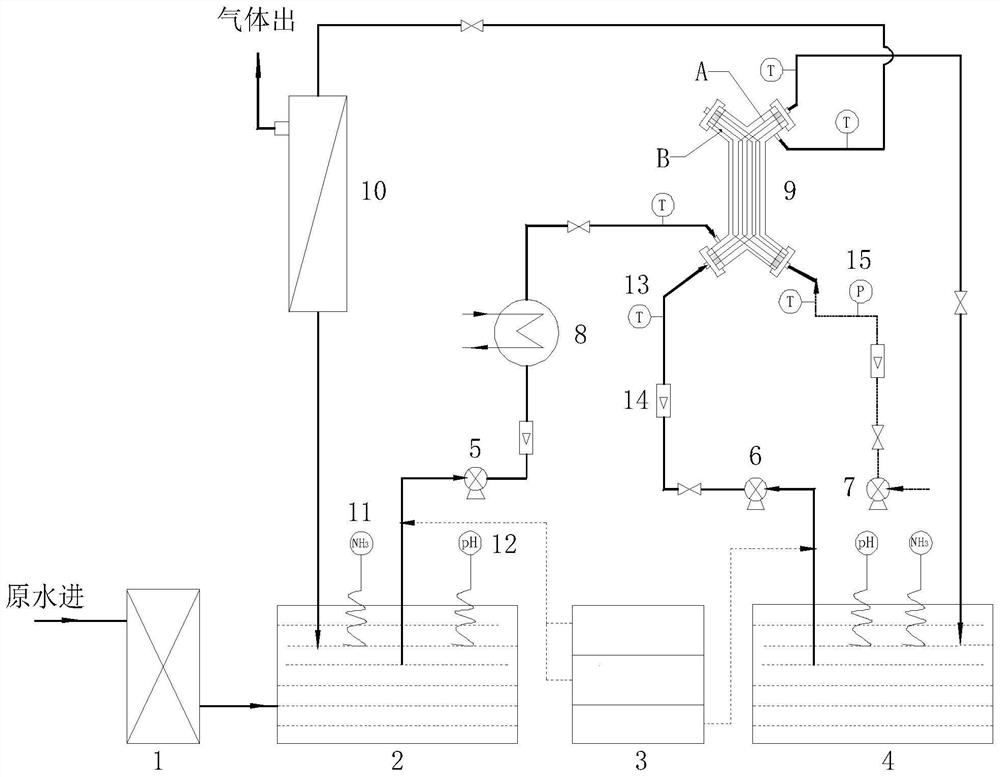

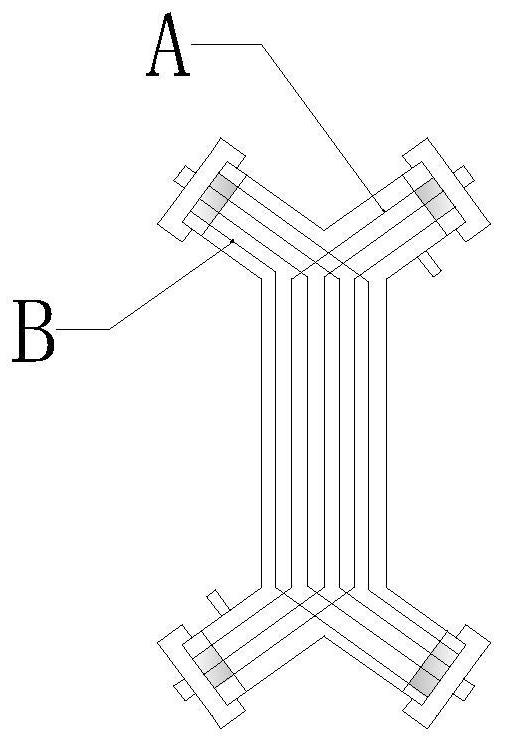

Device and method for dissolved gas film deamination

InactiveCN104817128AImprove ammonia removal efficiencyEasy to operateWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentHydrogenWater flow

The invention relates to a device and a method for dissolved gas film deamination and belongs to the technical field of waster water deamination. The method includes that potential of hydrogen (pH) value of ammoniated waster water is adjusted to 9-11 in advance by NaOH, the waster water is subjected to pretreatment through a 5-20 micrometer filter to enter a film deamination circulating trough, a dissolved gas pump fully mixes the ammoniated waste water with air to form dissolved gas water of which gas water dissolving gas volume ratio is smaller than 8%, the dissolved gas water is pumped into a dissolved gas film deamination module, the water is subjected to deamination by the dissolved gas film deamination module to return to the film deamination circulating trough, and waste water flowing direction after deamination is controlled through a first fluid flowing direction switching valve and a second fluid flowing direction switching valve. The dissolved gas film deamination module is connected with an ammonia recycling system, and removed ammonia gas is collected and recycled. Compared with traditional film deamination processes, the device and the method for dissolved gas film deamination have the advantages that vacuum deamination efficiency of ammonia-nitrogen wastewater can be remarkably improved, the device and the method are applicable to treatment of low and high ammonia-nitrogen wastewater, the operation is simple, the floor space is small, modularized design is easy, and the like.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

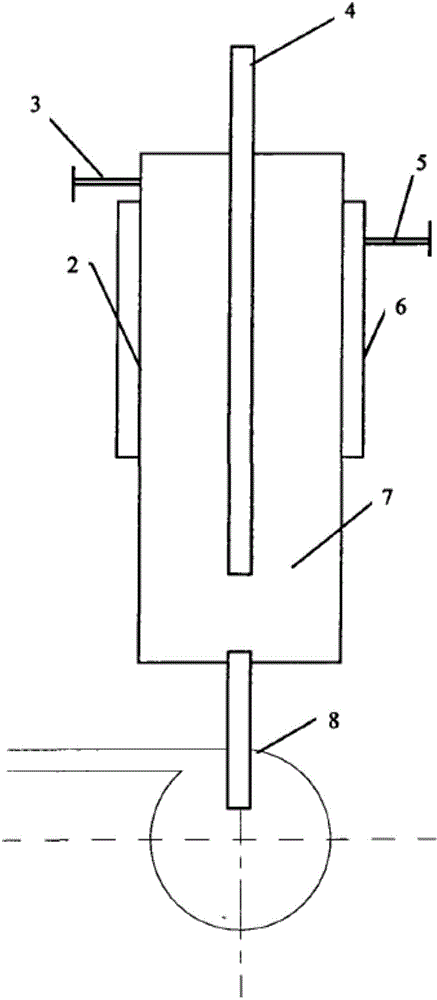

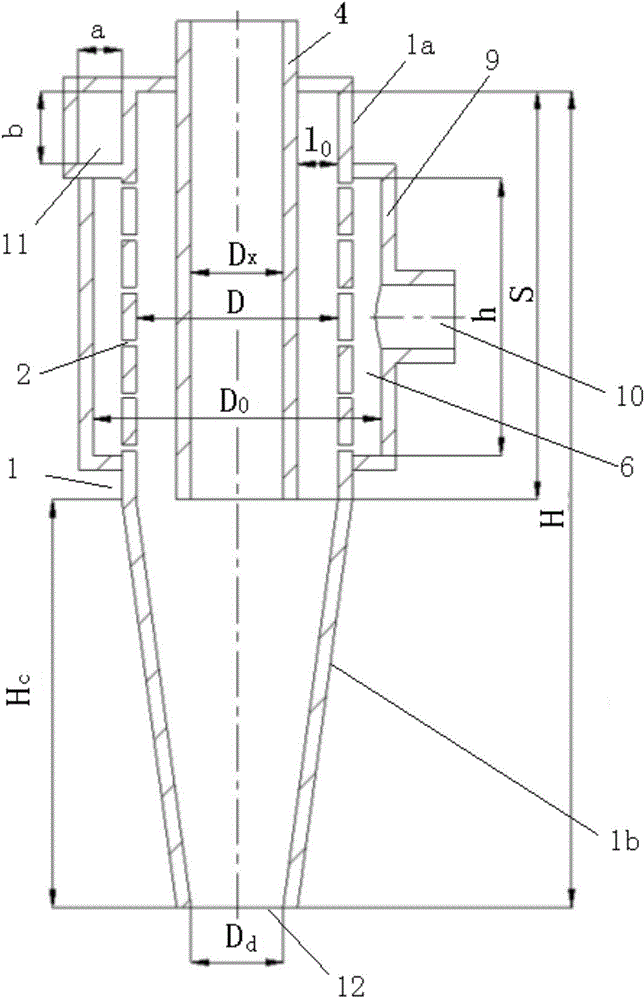

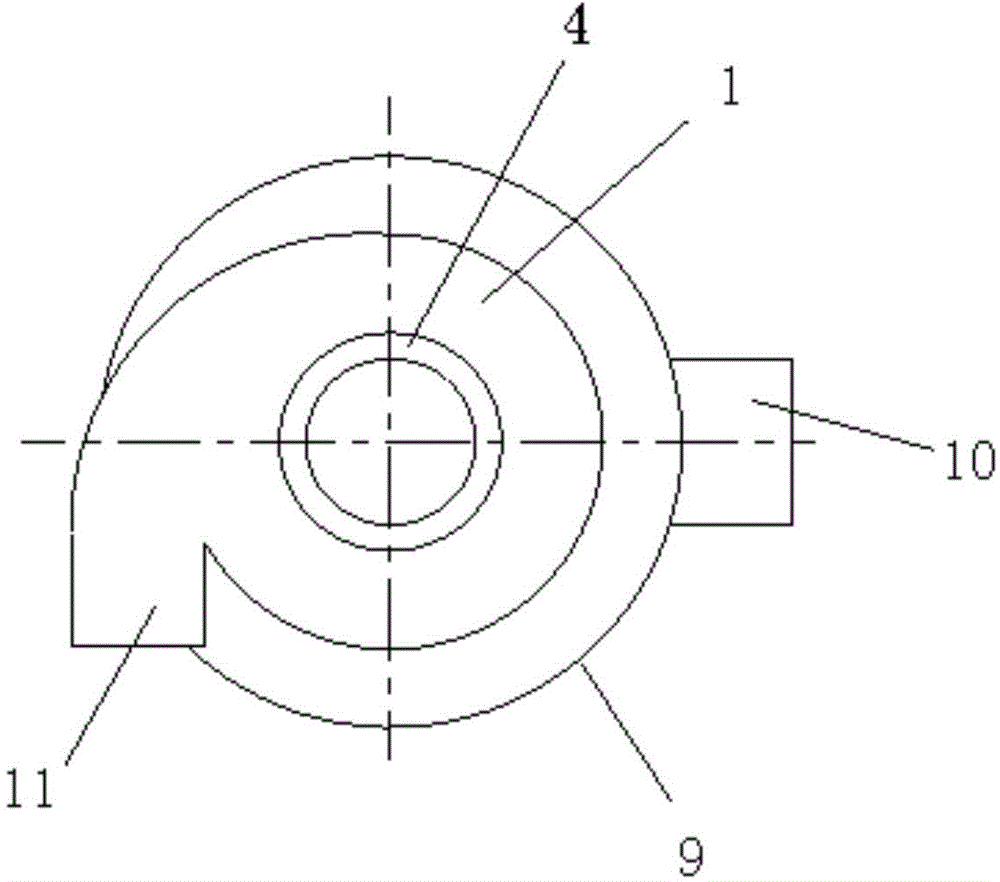

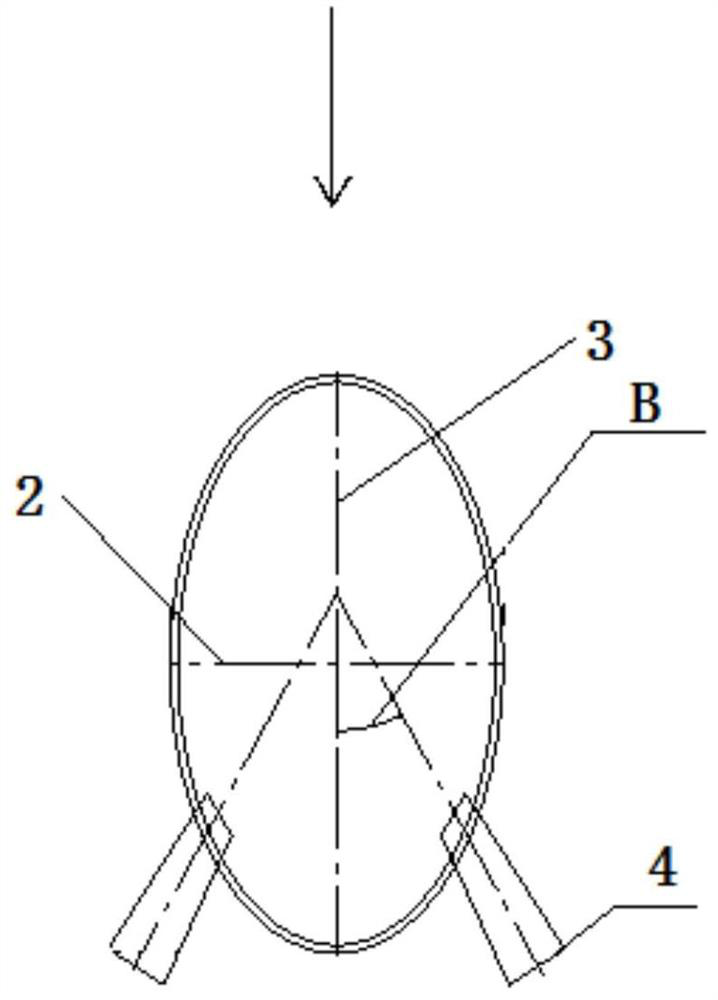

Hydraulic jet air cyclone

InactiveCN104815769AImprove energy efficiencyImprove ammonia removal efficiencyReversed direction vortexSquare arrayMass transfer

The invention discloses a hydraulic jet air cyclone. The hydraulic jet air cyclone comprises an air cyclone and a hydraulic jet atomizing chamber, wherein the air cyclone is formed by coating a center exhaust pipe with a cyclone cylinder; the upper end of the center exhaust pipe extends outside the cyclone cylinder, and the lower end is lower than the lower end of the hydraulic jet atomizing chamber; a cyclone port is formed in the cyclone cylinder; a cylindrical outer jacket is arranged at the periphery of the upper part of the cyclone cylinder, and is connected with the outer wall of the cyclone cylinder to form the hydraulic jet atomizing chamber; multiple spraying holes are formed in the outer wall of the connected cyclone cylinder from top to bottom; a liquid inlet is formed in the upper part of the hydraulic jet atomizing chamber; a diameter Dx of the center exhaust pipe is 0.5-0.6 d mm; an insertion depth S of the center exhaust pipe is 0.5-0.75H mm; the multiple spraying holes are arranged on the outer wall of the cylindrical cylinder in a square array form; and a length h of the spraying hole area is 0.6-1S mm. The hydraulic jet air cyclone can realize high-efficiency mass transfer of gas and liquid.

Owner:CHONGQING UNIV OF TECH

Deamination new process by alkaline hydrolysis of nitrile compounds

ActiveCN101993384ALess investment in equipmentImprove ammonia removal efficiencyOrganic compound preparationAmino-carboxyl compound preparationMaterial consumptionAminoacetonitrile

The invention provides a new deamination process method for preparing amino acids by alkaline hydrolysis of nitrile compounds (such as aminoacetonitrile, anilinoacetonitrile, iminodiacetonitrile and the like). The method can control the reaction temperature by decompression control of deamination degree, realize continuous fast large-scale alkaline hydrolysis and realize fast and high-efficient complete removal of free ammonia. The method can greatly improve the removal rate of ammonia, the recovery rate of the ammonia and the product quality, reduce material consumption and energy consumption, reduce equipment investment and achieve the purposes of energy conservation and emission reduction.

Owner:BEIJING ZIGUANG YINGLI CHEM TECH CO LTD

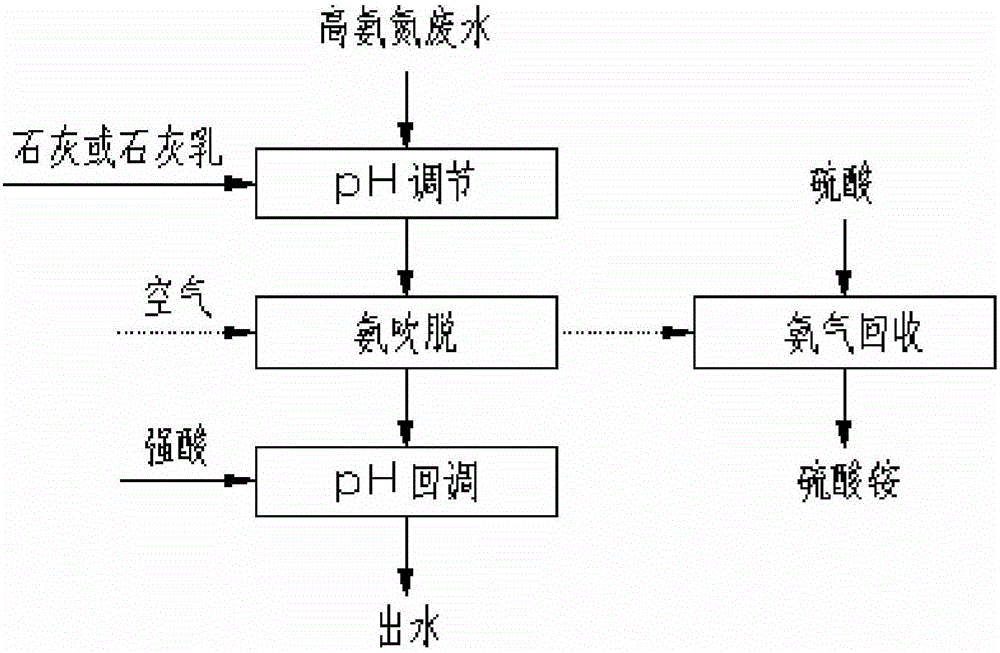

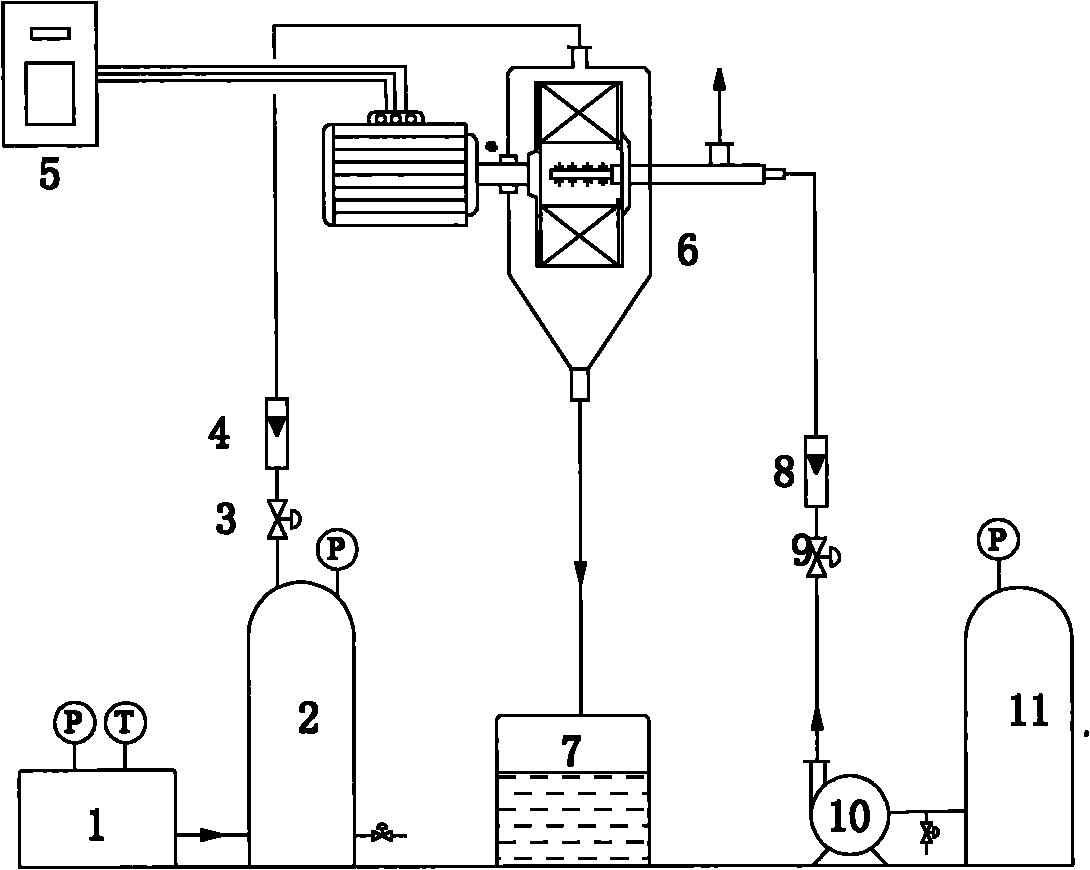

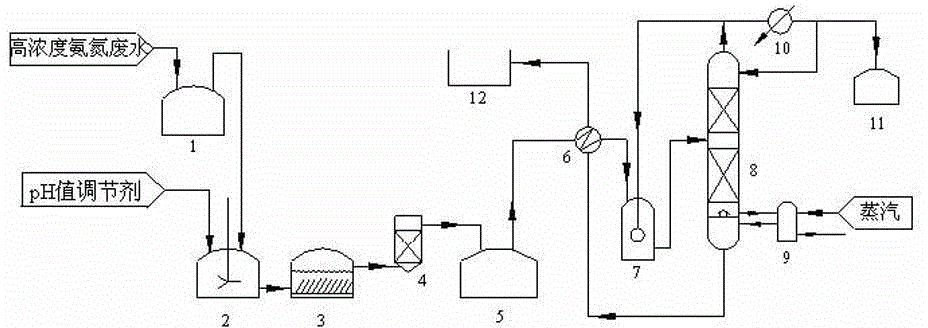

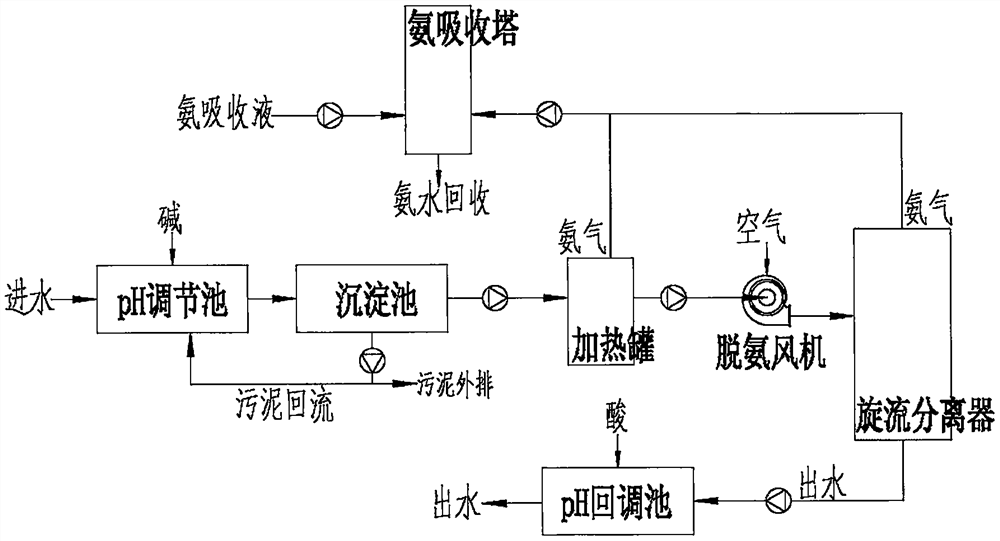

Ammonia stripping process and device for high-ammonia-nitrogen wastewater

InactiveCN106396184AReduce usageImprove ammonia removal efficiencyWater contaminantsDispersed particle separationSludgePollution

The invention relates to an ammonia stripping process and device for high-ammonia-nitrogen wastewater. By arranging a sedimentation process after pH regulation by adding alkali and an ammonia stripping process to be performed in a closed reaction device, performing aeration by means of jet-flow aeration and fully utilizing waste heat of a biochemical system to increase the temperature of high-ammonia-nitrogen wastewater, the ammonia removing efficiency is greatly improved; by performing reflux on sediment sludge produced in the system, the amount of used lime or lime milk is saved, and finally ammonia gas produced in the system is absorbed by adopting sulfuric acid to obtain ammonium sulfate which is recycled as ammonia fertilizer, such that the entire system not only has no secondary pollution, but also is high in ammonia removing efficiency and is low in operating cost and the technique can be more widely popularized and applied.

Owner:SHANGHAI JINGYU ENVIRONMENT ENG

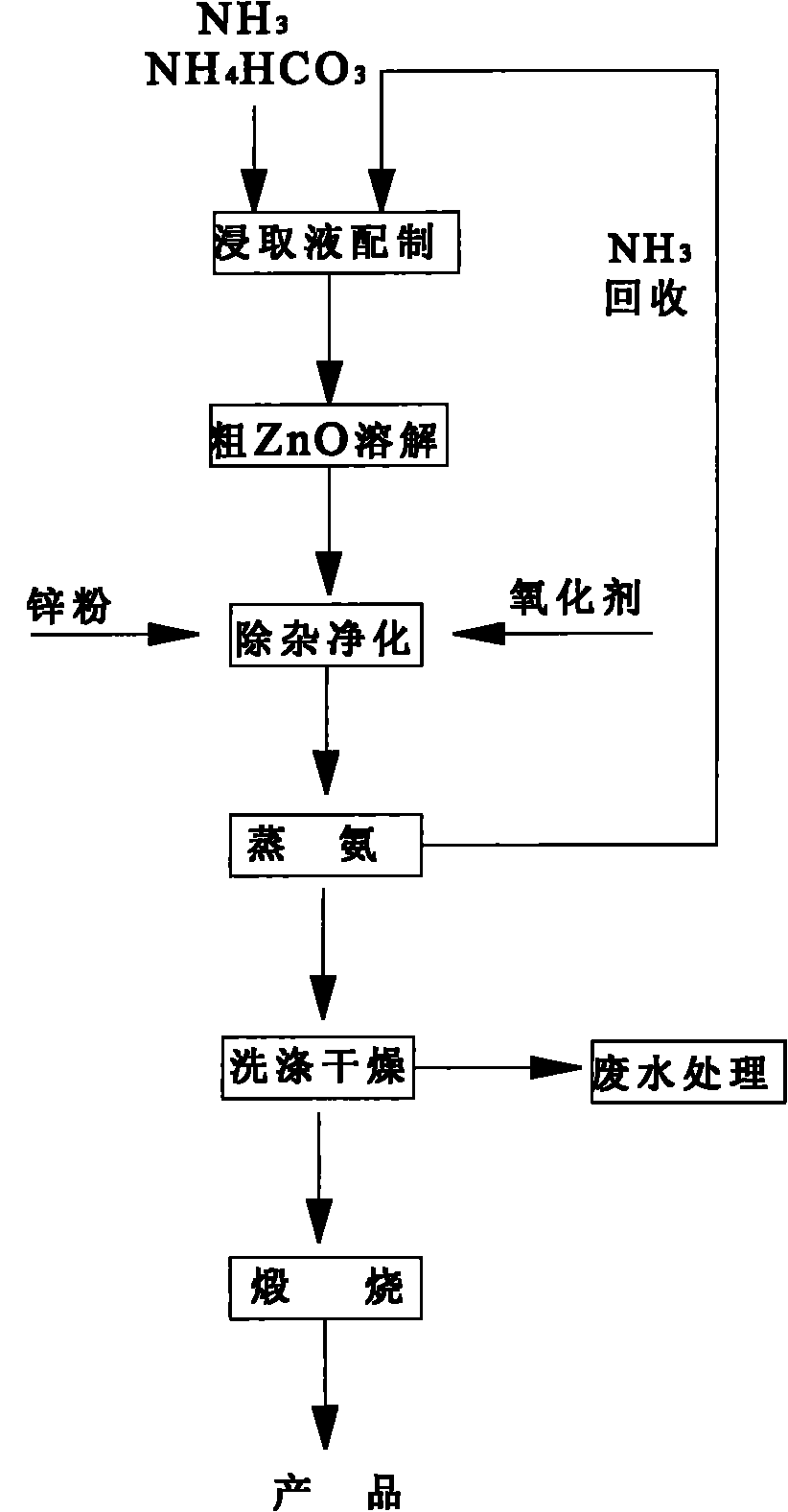

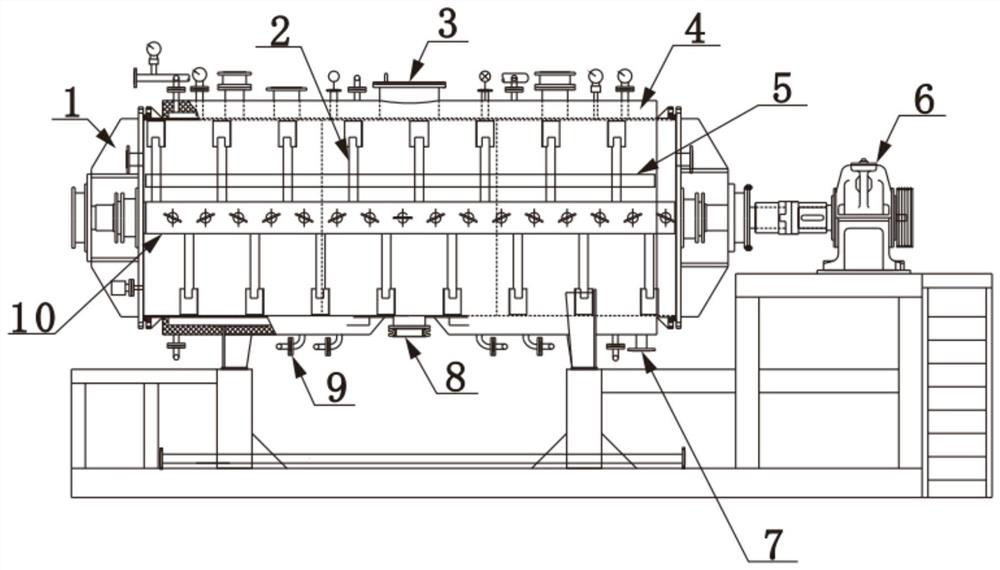

Method and device for preparing nano zinc oxide

The invention belongs to the technical field of zinc oxide preparation, in particular to a method and a device for preparing nano zinc oxide so as to realize a continuous process which has the advantages of higher deamination and zinc deposition rate under low energy consumption and preparation of higher quality nano zinc oxide. The preparation method comprises the following steps of: performing reaction on a zinc-ammonia complex and hot steam in a rotary packed bed to generate a zinc oxide precursor; and baking to prepare the nano zinc oxide. The device comprises a steam kettle, a zinc-ammonia complex solution storage tank, the rotary packed bed and a product storage tank, wherein the zinc-ammonia complex solution storage tank is connected with the liquid inlet of the rotary packed bed; the steam kettle is connected with a buffer tank; the gas outlet of the buffer tank is connected with the gas inlet of the rotary packed bed; and the liquid outlet of the rotary packed bed is connected with the product storage tank. The method has the advantages of simple process operation, low cost, high efficiency, and continuity; and the device has the advantages of obvious transmission effect, low power consumption, small equipment volume, self-cleaning function, and low possibility of scale formation and blockage.

Owner:ZHONGBEI UNIV

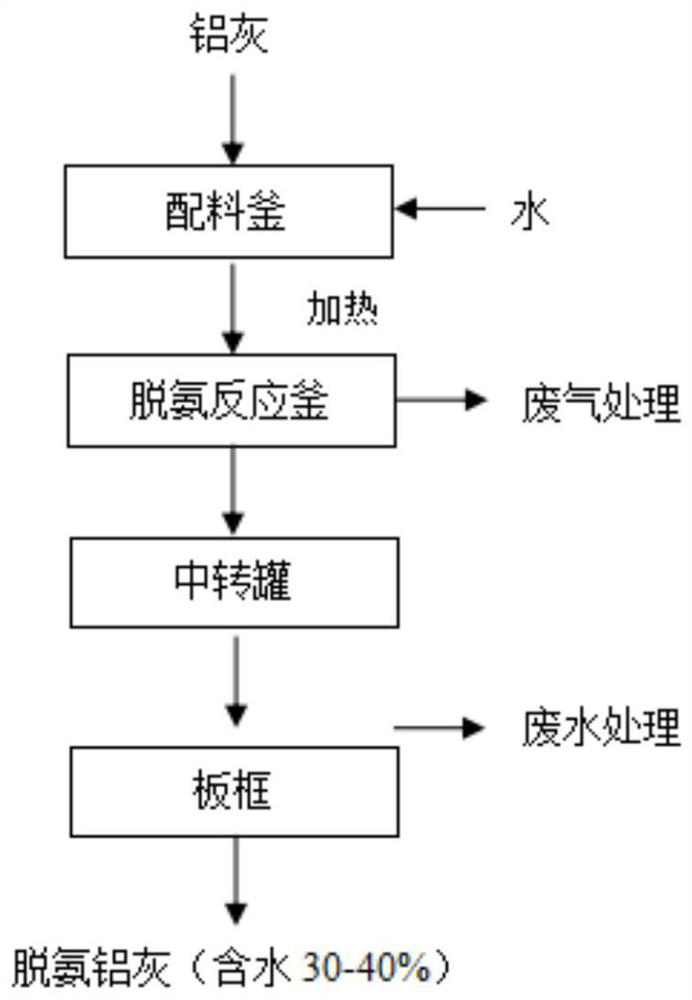

Aluminum ash deamination device and aluminum ash deamination process

ActiveCN112570418AExtended service lifeAvoid stickingSolid waste disposalProcess efficiency improvementExhaust valvePtru catalyst

The invention discloses an aluminum ash deamination device and an aluminum ash deamination process. The device comprises a closed cylinder, a feeding hole, a dust removal exhaust valve, a high-temperature exhaust valve, a pressure release valve and a water inlet are arranged at the upper portion of the outer part of the closed cylinder, a discharge port and a water outlet are formed in the lower portion of the outer part of the closed cylinder, and a heating part is arranged at the outer side of the closed cylinder; a central shaft is mounted on the axis of the closed cylinder and is connectedwith a speed reducer; rake teeth are arranged on the central shaft, and rake tooth blades are arranged at the top ends of the rake teeth; arc-shaped reinforcing plates are installed on the connectingportion of the central shaft and the rake teeth, and every two adjacent reinforcing plates can form a semi-arc-shaped structure; sweeping rods are mounted in rake tooth intervals at the same horizontal position; and two sweeping rods are arranged in total and are positioned in two opposite rake tooth intervals. According to the deamination process, the reaction temperature and pressure intensityof aluminum ash and a catalyst are controlled through the deamination device, and reaction conditions are flexibly adjusted in the reaction process, so that nitrogen in the aluminum ash is converted into ammonia gas, and the purpose of deamination is achieved.

Owner:四川科龙达环保股份有限公司

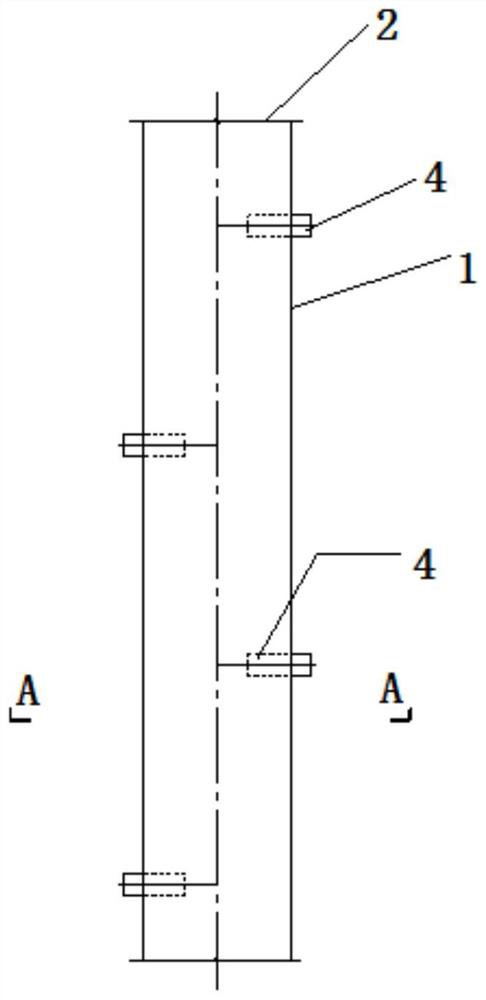

Ammonia spraying device and flue gas denitration device

PendingCN112870960AImprove bending resistanceReduce distortionGas treatmentDispersed particle separationFlue gasProcess engineering

The invention relates to the technical field of environmental protection, in particular to an ammonia spraying device and a flue gas denitration device.The ammonia spraying device comprises an ammonia spraying pipeline suitable for being horizontally arranged in a flue, wherein the cross section of the ammonia spraying pipeline is in an oval shape, the short axis of the oval shape is perpendicular to the flowing direction of flue gas in the flue, the long axis of the oval shape is parallel to the flowing direction of flue gas in the flue; and a nozzle which is arranged on the ammonia spraying pipeline. Due to the fact that the short axis is perpendicular to the flowing direction of the flue gas, on the premise that the length of the ammonia spraying pipeline is not changed, the projection area of the ammonia spraying pipeline is the product of the length of the short axis and the length of the ammonia spraying pipeline, the flue gas blocking area can be greatly reduced, the deamination efficiency of the system is guaranteed, and the system resistance is effectively reduced. The mass transfer path and area are increased, and the deamination efficiency is improved. In addition, due to the oval shape, flowing of the smoke can be guided, the smoke flows smoothly, and abrasion to the ammonia spraying pipeline is small.

Owner:CHINA HUADIAN ENG +1

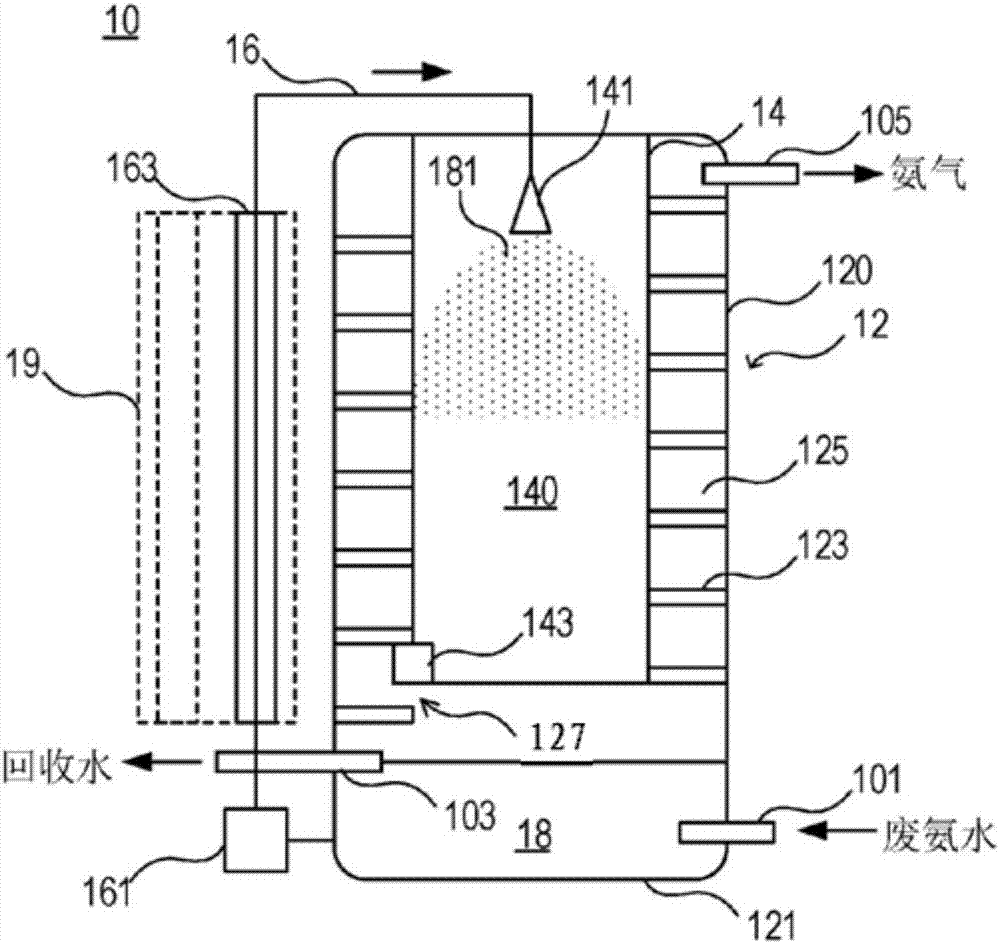

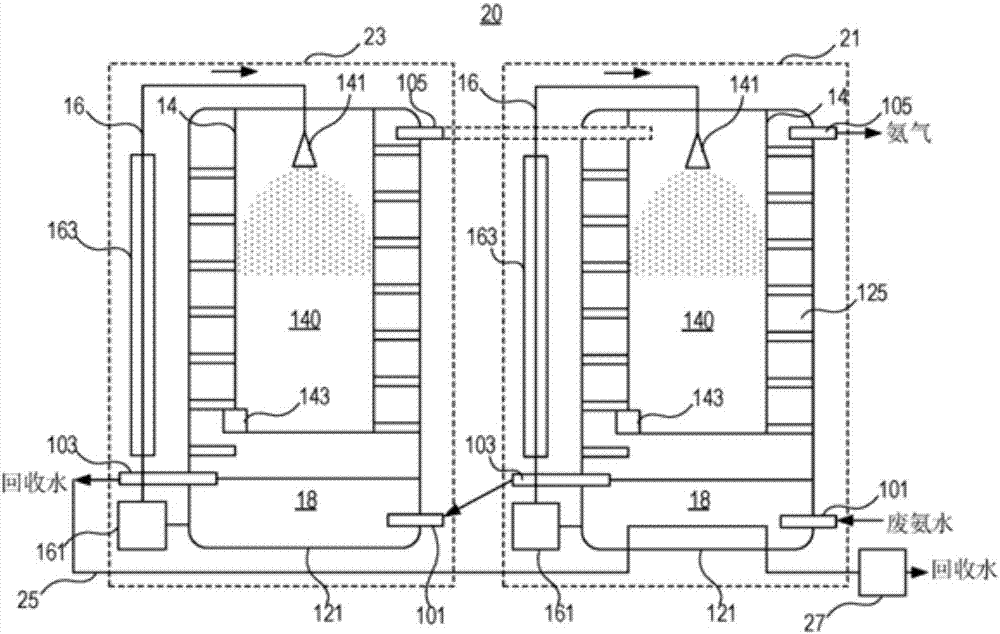

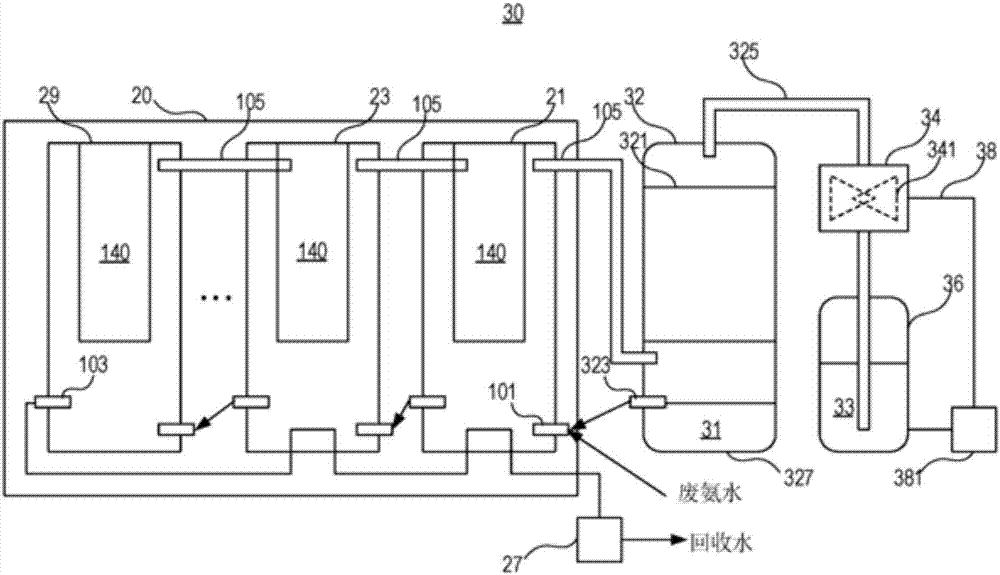

Treatment system for high-concentration ammonia-nitrogen wastewater

ActiveCN104891726AEasy to operateIncrease temperatureMultistage water/sewage treatmentAmmoniacal nitrogenNitrogen removal

The invention discloses a treatment system for high-concentration ammonia-nitrogen wastewater. The treatment system comprises a pretreatment system, a concentration-increasing and energy-saving device, a stripping tower, a condenser and an ammonia water storage tank which are connected sequentially. The treatment system has the advantages that the treatment system is simple to operate, equipment investment is low, ammonia-nitrogen removal efficiency is high, steam unit consumption in ammonia-nitrogen wastewater treatment is low, up-to-standard discharge can be achieved through one-step treatment, and finished ammonia water with high economic value can be recycled.

Owner:CHANGSHA HASKY ENVIRONMENTAL PROTECTION TECH DEV CO LTD

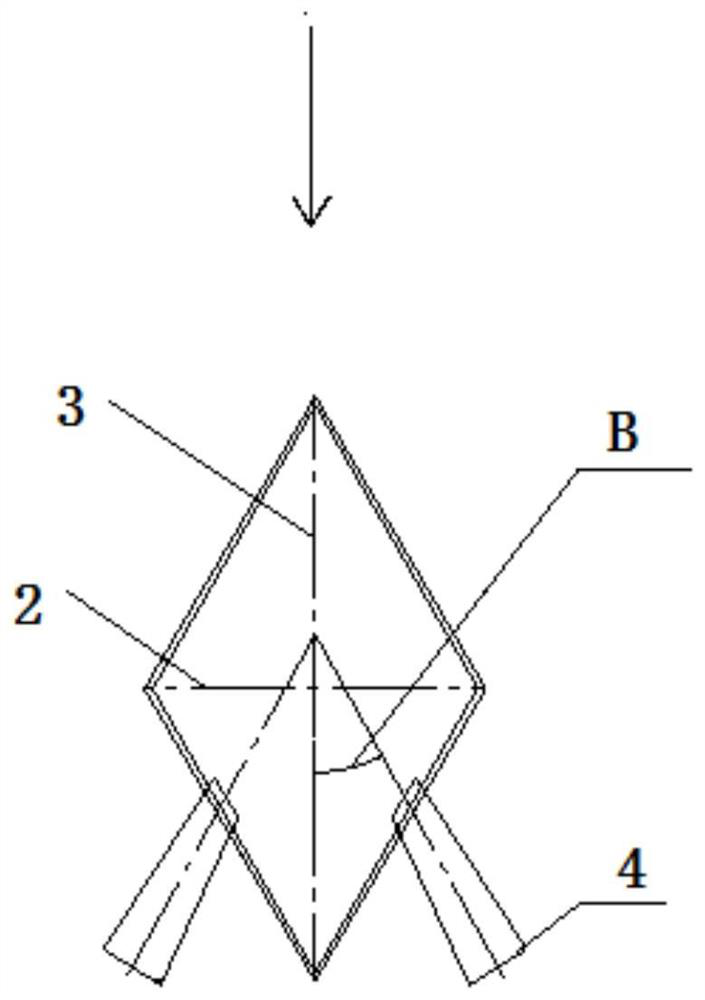

Ammonia spraying device and flue gas denitration device

PendingCN112973426AImprove bending resistanceReduce distortionGas treatmentDispersed particle separationThermodynamicsFlue gas

The invention relates to the technical field of environmental protection, in particular to an ammonia spraying device and a flue gas denitration device. The ammonia spraying device comprises an ammonia spraying pipeline suitable for being horizontally arranged in a flue, and a nozzle, wherein the cross section of the ammonia spraying pipeline is in a rhombus shape, the short diagonal line of the rhombus is perpendicular to the flowing direction of flue gas in the flue, the long diagonal line of the rhombus is parallel to the flowing direction of flue gas in the flue; and the nozzle is arranged on the ammonia spraying pipeline. As the short diagonal is perpendicular to the flowing direction of the flue gas, the projection area of the ammonia spraying pipeline is the product of the length of the short diagonal and the length of the ammonia spraying pipeline on the premise that the length of the ammonia spraying pipeline is not changed, the blocking area to the flue gas can be greatly reduced, the deamination efficiency of the system is ensured, the resistance of the system is effectively reduced, the mass transfer path and area are increased, and the deamination efficiency is improved. In addition, due to the rhombus shape, the flow of the flue gas can be guided, the flue gas flows smoothly, and the abrasion to the ammonia spraying pipeline is small.

Owner:CHINA HUADIAN ENG +1

Device and method for treating escaped ammonia of tunnel kiln for calcining denitration catalyst

PendingCN110841477AImprove the capture effectReduce pollutionGas treatmentDispersed particle filtrationTunnel kilnPtru catalyst

The invention relates to the technical field of waste gas treatment of tunnel kilns, specifically to a device and a method for treating escaped ammonia of a tunnel kiln for calcining a denitration catalyst. The device comprises a tunnel kiln main body, a waste gas collecting pipeline arranged in the tunnel kiln main body, and a waste gas reactor connected with and arranged on the waste gas collecting pipeline, wherein an exhaust fan is arranged on a connecting pipeline of the waste gas reactor and the waste gas collecting pipeline; and a dust removal filter cloth layer, a blowback unit and a multi-stage ammonia removal filter cloth layer are sequentially arranged in the waste gas reactor in a direction from an inlet to an outlet. The device provided by the invention directly utilizes the waste gas collection pipeline in the tunnel kiln to convey waste gas to the waste gas reactor in a centralized manner, respectively treat and remove dust particles and the escaped ammonia through a filter cloth in the dust removal filter cloth layer, is reasonable in design, high in economical efficiency and small in occupied area, can efficiently remove ammonia and impurities from the waste gas ofthe tunnel kiln, effectively purifies the waste gas of the tunnel kiln, and greatly reduces air pollution caused by the waste gas of the tunnel kiln.

Owner:XIAN THERMAL POWER RES INST CO LTD

Ammonia spraying device and flue gas denitration device

PendingCN112973427AImprove bending resistanceReduce distortionGas treatmentDispersed particle separationFlue gasProcess engineering

The invention relates to the technical field of environmental protection, in particular to an ammonia spraying device and a flue gas denitration device. The ammonia spraying device comprises an ammonia spraying pipeline suitable for being horizontally arranged in a flue, the cross section of the ammonia spraying pipeline being rectangular, the side, perpendicular to the flowing direction of flue gas in the flue, of the cross section of the ammonia spraying pipeline being a short side, the side parallel to the flowing direction of flue gas in the flue being a long side, and the surface, facing the flowing direction of the flue gas, of the ammonia spraying pipeline being a windward side; a flow guide part arranged on the windward side of the ammonia spraying pipeline; and a nozzle arranged on the ammonia spraying pipeline. On the premise that the length of the ammonia spraying pipeline is not changed, the projection area of the ammonia spraying pipeline can be greatly reduced, the blocking area for flue gas is reduced, the deamination efficiency of the system is ensured, the resistance of the system is effectively reduced, the mass transfer path and area are increased, and the deamination efficiency is improved. The flow guide part is arranged on the windward side of the ammonia spraying pipeline, so that the flowing of flue gas can be guided, the flue gas is prevented from directly colliding with the windward side of the ammonia spraying pipeline, and the abrasion of the windward side can be reduced.

Owner:CHINA HUADIAN ENG +1

Treatment Technology of High Concentration Ammonia Nitrogen Wastewater

ActiveCN104926012BIncrease temperatureReduce steam consumptionMultistage water/sewage treatmentHigh concentrationAmmoniacal nitrogen

Owner:CHANGSHA HASKY ENVIRONMENTAL PROTECTION TECH DEV CO LTD

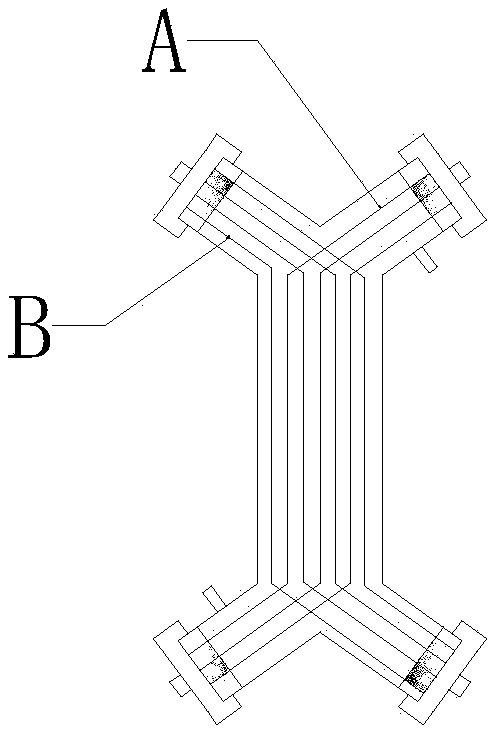

Treatment device for high-ammonia-nitrogen wastewater containing organic solvent

PendingCN106966530AToleratedCorrosion resistanceWater contaminantsTreatment involving filtrationOrganic solventPolypropylene

The invention discloses a treatment device for high-ammonia-nitrogen wastewater containing an organic solvent. The treatment device comprises a wastewater deamination treatment unit, wherein the wastewater deamination treatment unit comprises at least one deamination membrane module, as well asa water distribution pipe, a water collecting pipe and a plurality of hollow fiber membrane filaments, which are mounted in a casing; one end of each hollow fiber membrane filament is connected with the water distribution pipe, and an opposite end is connected with the water collecting pipe to form a membrane filament array; the membrane filament arrayis sleeved witha flow guide baffle plate; and the casing, the water distribution pipe, the water collecting pipe, the hollow fiber membrane filaments and the flow guide baffle plate are made of a polypropylene material. The treatment device provided by the invention has corrosion resistance, and tolerance to the organic solvent, and can carry out deamination treatment on the high-ammonia-nitrogen wastewater containing the organic solvent, so that the application range is enlarged..

Owner:苏州依斯倍环保装备科技有限公司

Ammonia steam waste heat utilization device for ammonia distillation

PendingCN112978761AReduce consumptionReduce adhesionEnergy inputSolution crystallizationThermodynamicsProcess engineering

The invention relates to an ammonia steam waste heat utilization device for ammonia distillation, which comprises an ammonium sulfate mother liquor heat exchanger, an ammonia condensate tank and an ammonia condensate pump, the ammonium sulfate mother liquor heat exchanger and the ammonia condensate pump are provided with the ammonia condensate tank, and the ammonia condensate tank is connected with the ammonium sulfate mother liquor heat exchanger and the ammonia condensate pump through a pipeline. The ammonium sulfate mother liquor heat exchanger is provided with an ammonia steam inlet, an ammonia steam outlet, a mother liquor inlet and a mother liquor outlet, an adjusting valve is arranged on a mother liquor inlet pipeline, the flow of mother liquor entering the heat exchanger is controlled through the opening degree of the adjusting valve, an adjusting valve is arranged on an ammonia steam inlet pipeline, and the opening degree of the adjusting valve is automatically adjusted according to the temperature of mother liquor in a mother liquor outlet pipeline.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

An integrated process for low-temperature flue gas desulfurization, denitrification and ammonia removal

ActiveCN103816780BImprove ammonia removal efficiencyImprove desulfurization efficiencyDispersed particle separationEmission standardEvaporation

The invention relates to an integrated low-temperature flue gas desulfurization, denitration and ammonia removal process suitable for the desulphurization and the denitration of coke oven flue waste gas of which flue gas temperature is greater than 180 DEG C and the content of SO2 is less than 150 mg / Nm3. According to the process, dry desulphurization is performed before denitration according to a fluidized principle, ammonia gas produced by evaporating residual ammonia water at an ammonia evaporation workshop section in a coking plant is used as a reducing agent, a cloth bag combining with an ammonia removal catalyst composite structure is used as a dust removing and denitration manner, and during efficient desulphurization and denitration, an escape amount of ammonia is controlled to be lower than a national emission standard value. Compared with the prior art, the process has the benefits that 1), the integrated desulphurization, denitration and ammonia removal efficiency is high; 2) the denitration manner is unique, and the structural form of equipment is advanced; 3) ash removal is simple; 4) the energy is saved, and the operating cost and the once investment are reduced; 5) residual ammonia water in a coal gas purification process is fully recycled; 6) the residual heat is fully recycled.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Step-by-step pressure reducing deacidification and deamination method and system for coal chemical industry wastewater

InactiveCN106554115AReduce mutual interferenceReduce cloggingFatty/oily/floating substances removal devicesMultistage water/sewage treatmentHigh concentrationChemical synthesis

The invention discloses a step-by-step pressure reducing double-reactor deacidification and deamination method and system for coal chemical industry wastewater. Waste water generated due to coal gasification and coking and containing volatile acid and ammonia nitrogen firstly passes through a deacidification reactor to remove acidic gas, then pressure reducing is performed, the waste water enters a deamination reactor, and the pressure difference of the two reactors is 20-200 KPa. Certain-contraction ammonium ions in NaOH solution decomposition water are added into the upper portion of the deamination reactor, gas exhausted out of the top of the deamination reactor is subjected to double flash evaporation and passes through an ammonia concentration reactor so that concentrated ammonia gas can be collected, and deaminated waste water flowing out of the bottom of the deamination reactor is conveyed into a subsequent workshop section for treatment after exchanging heat with to-be-treated waste water. After the method is adopted for treatment, the sulfur remaining amount of the waste water is smaller than 20 mg / L, and the ammonia remaining amount is smaller than 100 mg / L. The method has the beneficial effects of being high in deacidification and deamination precision, stable in running, low in energy consumption, mature in technology and easy to operate and control, can be used for treating the waste water generated in the coal gasification, coking and chemical synthesis process and containing high-concentration volatile acid and ammonia nitrogen.

Owner:西安润格环保科技有限公司

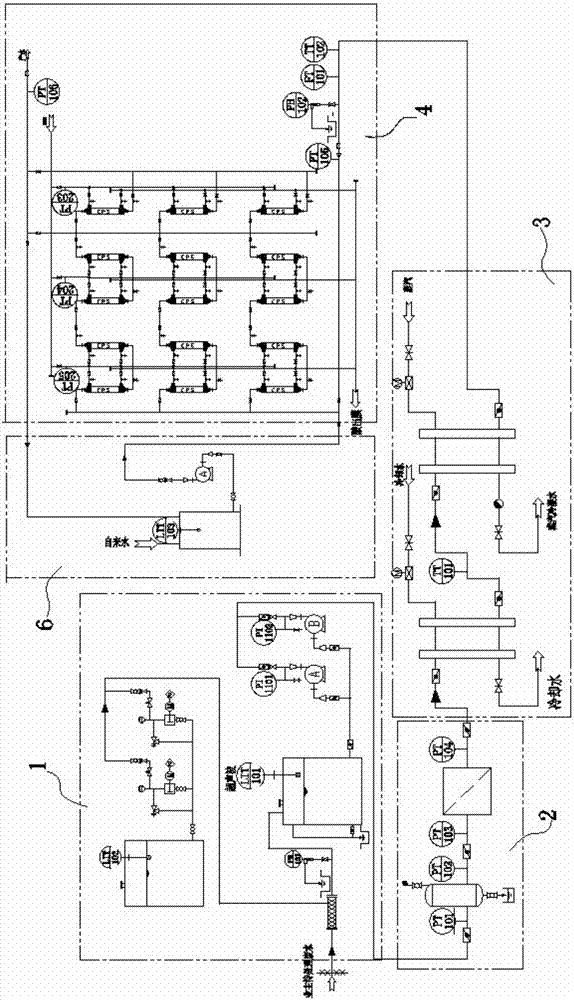

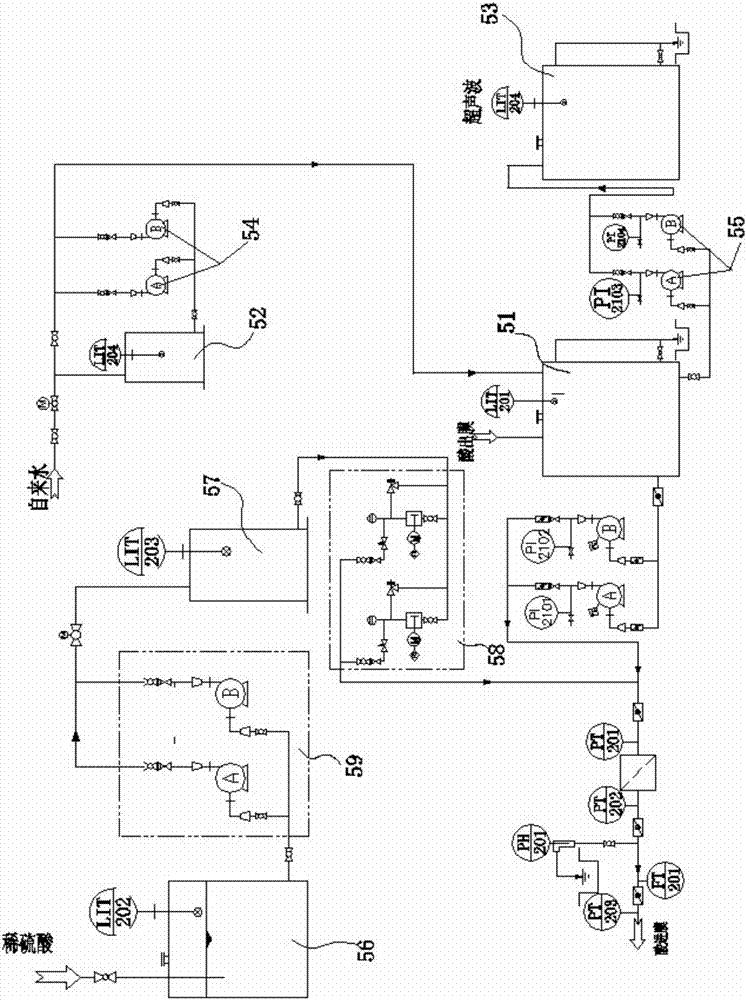

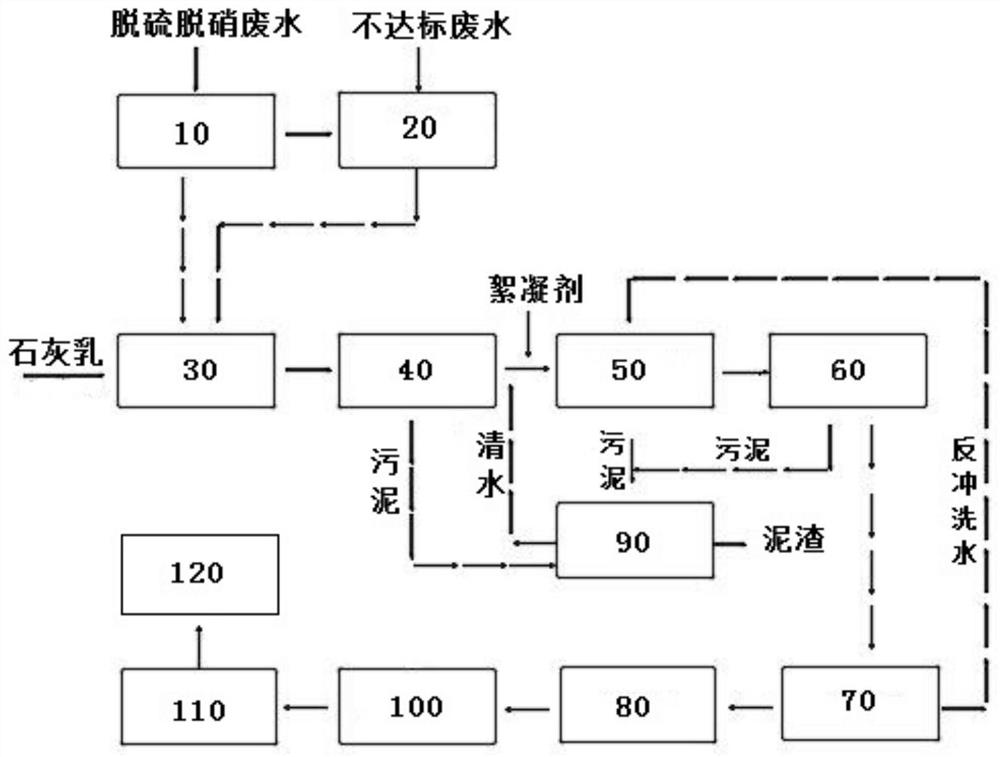

Wastewater treatment system suitable for active coke desulfurization and denitrification technology

PendingCN111762945AEnsure complete removalImprove ammonia removal efficiencyWater treatment parameter controlGas treatmentDistillationWater collection

The invention discloses a wastewater treatment system suitable for an activated coke desulfurization and denitrification technology. The wastewater treatment system comprises a pH regulating system, asedimentation system and a distillation denitrification system, wherein the pH regulating system comprises a water collection regulating pool, an accident pool and a pH regulating pool, the water collection regulating pool and the accident pool are respectively connected to the pH regulating pool through pipelines; and the sedimentation system comprises a primary sedimentation pool, a high-efficiency sedimentation pool, an air flotation machine, a sand filtration system and an intermediate water pool which are sequentially connected through pipelines, the pH regulating pool is connected to the primary sedimentation pool, and the sand filtration system is connected to the high-efficiency sedimentation pool through a pipeline. The wastewater treatment system is small in occupied area and high in land utilization rate; chemical separation wastewater generated in the activated coke process and residual ammonia water are distilled in combination with distillation denitrification, the NH3-Ncontent of the wastewater is reduced, and removal of wastewater sludge and high deamination efficiency can be guaranteed at the same time.

Owner:上海电气电站环保工程有限公司

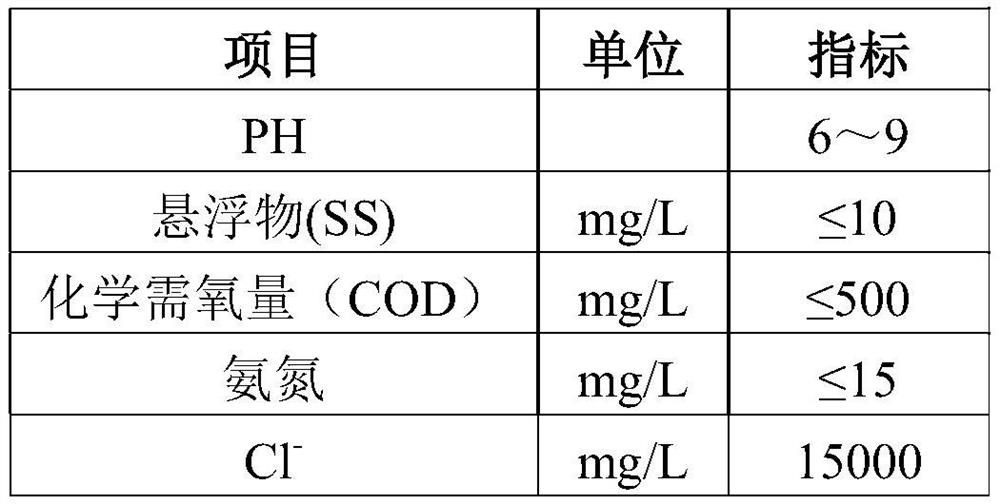

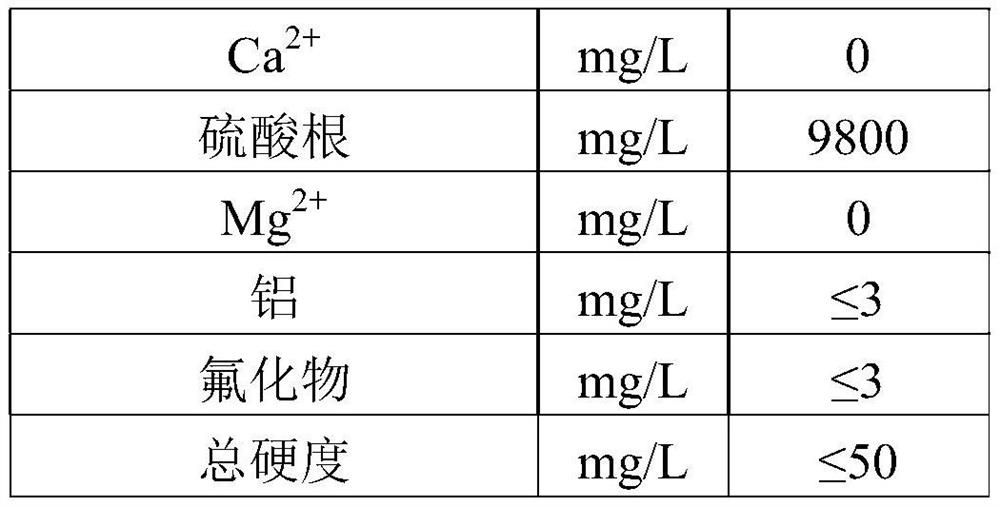

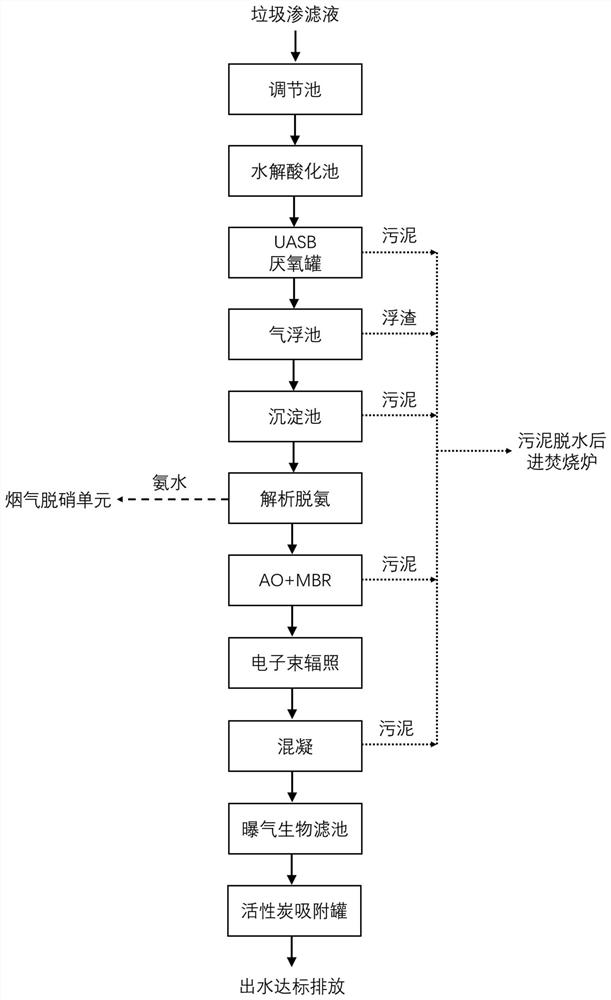

Leachate treatment system and method suitable for waste incineration power plant

PendingCN111847798ASolve processing problemsGuaranteed uptimeWater contaminantsWater aerationActivated carbonWater flow

The invention relates to the technical field of sewage treatment, in particular to a leachate treatment system and method suitable for a waste incineration power plant. The leachate treatment system suitable for the waste incineration power plant comprises an adjusting tank, a hydrolysis acidification tank, a UASB anaerobic reaction tank, an air floatation tank, a sedimentation tank, an analyticaldeamination tower, an A / O reaction tank, an MBR membrane tank, electron beam irradiation equipment, a coagulation tank, a biological aerated filter and an activated carbon filter which are sequentially connected in the water flow direction. According to the leachate treatment system suitable for the waste incineration power plant, disclosed by the invention, the water quality of leachate generated by the waste incineration power plant after treatment can reach the emission limit value standard of the Control Standard of Domestic Refuse Landfill (GB 16889-2008), and the method has the advantages of good treatment effect, low cost, stable operation and no generation of concentrated phase liquid after membrane separation, so that the method has good application and popularization prospects,and can protect stable production, cost reduction and efficiency increase of a waste incineration plant.

Owner:中节能工程技术研究院有限公司

Membrane absorption deamination method and membrane absorption deamination system based on direct contact type microporous aeration enhancement

ActiveCN111252932AReduce wettingReduce the problem of hydrophilizationWater treatment parameter controlSemi-permeable membranesHydrophilizationPhysical chemistry

The invention relates to the technical field of wastewater treatment, particularly to a membrane absorption deamination system and a membrane absorption deamination method based on direct contact typemicroporous aeration enhancement. In the direct contact type aeration enhanced membrane absorption deamination process, membrane surface pollution deposition can be reduced through aeration, so thatthe problems of membrane wetting and hydrophilization caused by membrane pollution are reduced, and the cleaning frequency of a membrane assembly is reduced; and a gas-liquid two-phase flow can be formed through aeration stripping, so that the resistance in a mass transfer process can be effectively reduced, the volatilization rate of ammonia in wastewater and the transmembrane speed of ammonia are increased, and the deamination efficiency is improved. The method has great advantages in the aspects of investment cost and operation cost, and is a novel wastewater deamination and ammonia recovery technology which is energy-saving, consumption-reducing and sustainable in resource development.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI

Low-concentration ammonia water deamination device and system and application thereof in ammonia water preparation system

InactiveCN107215881AReduce mass transfer resistanceImprove ammonia removal efficiencyEnergy inputAmmonia preparation/separationEvaporationEngineering

The invention discloses a low-concentration ammonia water deamination device and system and application thereof in an ammonia water preparation system. The low-concentration ammonia water deamination device disclosed by the invention comprises an inner cylinder, an outer cylinder, a pressurization pipeline and a heat exchanger, wherein a spiral channel is further arranged between the outer cylinder and the inner cylinder. Low-concentration ammonia water contained at the bottom of the outer cylinder is pressurized by the pressurization pipeline and then is sprayed out and atomized through an atomizing nozzle to form droplets, part of ammonia and water are evaporated in an evaporation region of the inner cylinder to form ammonia gas and vapor, and the droplets are separated from the ammonia gas and the vapor by means of the spiral channel, so that ammonia water having a lower concentration is obtained, and a high-efficiency deamination effect is achieved.

Owner:ASIA AN TECHNICS CO LTD

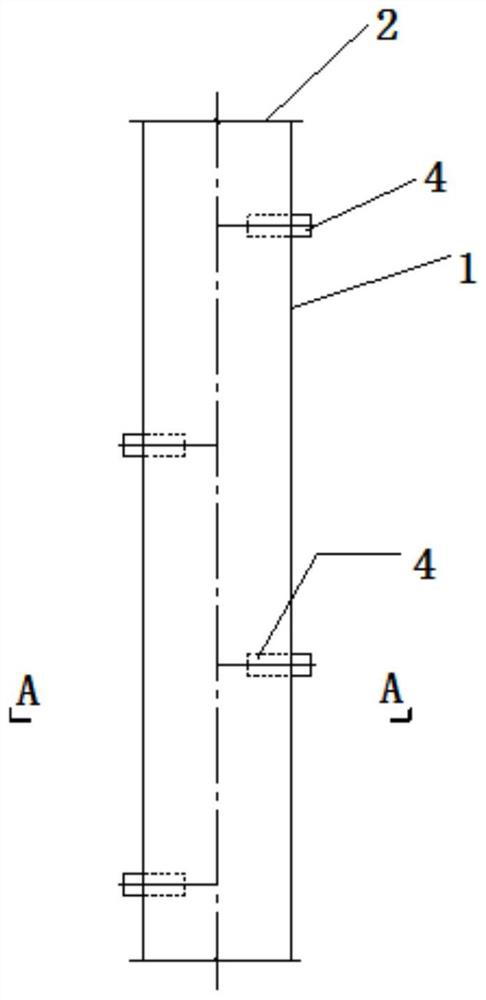

Ammonia stripping process and ammonia stripping device for high-concentration ammonia-nitrogen wastewater

PendingCN111620500AReduce dosageImprove ammonia removal efficiencyWater contaminantsMultistage water/sewage treatmentAmmoniacal nitrogenFluid phase

An ammonia stripping process for high-concentration ammonia-nitrogen wastewater comprises a pH regulating tank, a sedimentation tank, a heating tank, a deamination fan, a cyclone separator, a pH back-regulating tank and an ammonia absorption tower. PH and water temperature of inlet water are adjusted to create an optimal ammonia stripping condition. The sedimentation tank is provided with sludge backflow, and the use amount of alkali is saved. Inlet water is atomized in the deamination fan under the action of an impeller rotating at a high speed and is sufficiently and violently collided and mixed with air, free ammonia in the water is transferred from a liquid phase into a gas phase, enters the air and is separated from the water in the cyclone separator. The device is good in gas-water mixing effect, high in deamination efficiency and low in energy consumption. Ammonia gas generated in the wastewater treatment process is absorbed by clear water in the ammonia absorption tower, diluteammonia water is generated and recycled, resources are saved, and secondary pollution is avoided.

Owner:湖南迪亚环境工程股份有限公司

Membrane absorption deamination method and system based on direct contact microporous aeration enhancement

ActiveCN111252932BReduce wettingReduce the problem of hydrophilizationWater treatment parameter controlSemi-permeable membranesHydrophilizationMembrane fouling

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI

Method of electrolyzing wastewater containing ammonia nitrogen and apparatus therefor

ActiveCN101198551BImprove decomposition efficiencySuppress generationWater treatment parameter controlWater contaminantsElectrolysisMetallic materials

A method of electrolyzing a wastewater containing ammonia nitrogen that is capable of avoiding any drop of current efficiency, enhancing the efficiency of ammonia decomposition and carrying out safe and efficient treatment of all types of nitrogen-containing wastewaters; and an apparatus therefor. There is provided an electrolyzer apparatus for a wastewater containing ammonia nitrogen, comprisingconditioning tank (11) for inflow of a wastewater containing ammonia nitrogen; electrolysis tank (12) for electrolyzing wastewater (20) fed from the conditioning tank in the presence of chloride ion;and circulation pump (13) for circulating the wastewater through the conditioning tank (11) and the electrolysis tank (12), wherein the electrolysis tank (12) is adapted to carry out electrolysis of the wastewater within the pH range of 5 to <8. Preferably, the electrolysis tank (12) thereinside is provided with a catalyst member consisting of a metal material so as to accelerate the decomposition reaction of ammonia nitrogen.

Owner:MITSUBISHI HEAVY IND ENVIRONMENTAL & CHEM ENG CO LTD

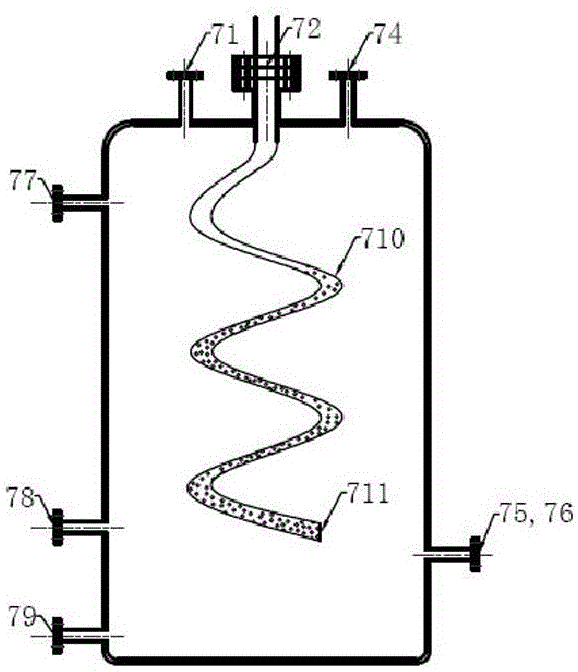

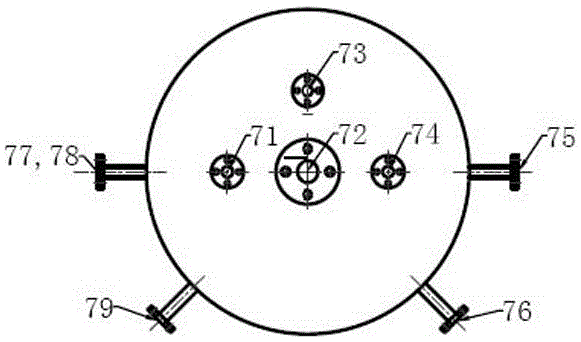

A kind of treatment method of ammonia nitrogen wastewater

ActiveCN111137936BAccelerate evaporationFacilitated ionizationWater contaminantsSustainable biological treatmentAmmoniacal nitrogenThermodynamics

The invention relates to a method for treating ammonia nitrogen wastewater, comprising: A1 pretreating ammonia nitrogen wastewater; A2 performing heat exchange treatment on the pretreated ammonia nitrogen wastewater, and then performing concentration and temperature increase treatment; A3 adopting a stripping tower to treat the heated ammonia nitrogen The waste water is stripped to obtain ammonia-containing steam and deamination waste water; A4 connects the ammonia-containing steam in step A3 to step A2 to enrich the ammonia-nitrogen waste water; A5 heats the deamination waste water in step A3 to produce Secondary steam and high-temperature deammonization wastewater, and the secondary steam is connected to the stripping tower to supplement the steam in the stripping tower. The stripping tower in step A3 includes a tank body, a spraying device and a steam spraying device, and the spraying device includes a spraying pipe, a spraying head rotatably installed on the end of the spraying pipe and a driving part. The steam injection device comprises a steam pipe, a steam injection head rotatably installed on the end of the steam pipe and a rotating part. The present invention has the effect of high ammonia removal efficiency.

Owner:上海天成环境保护有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com