Device and method for treating escaped ammonia of tunnel kiln for calcining denitration catalyst

The technology of denitration catalyst and treatment device is applied in the field of fugitive ammonia treatment device, which can solve the problems of large floor space, high engineering cost and long process route, and achieve the effects of small floor space, pollution reduction and simple process operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

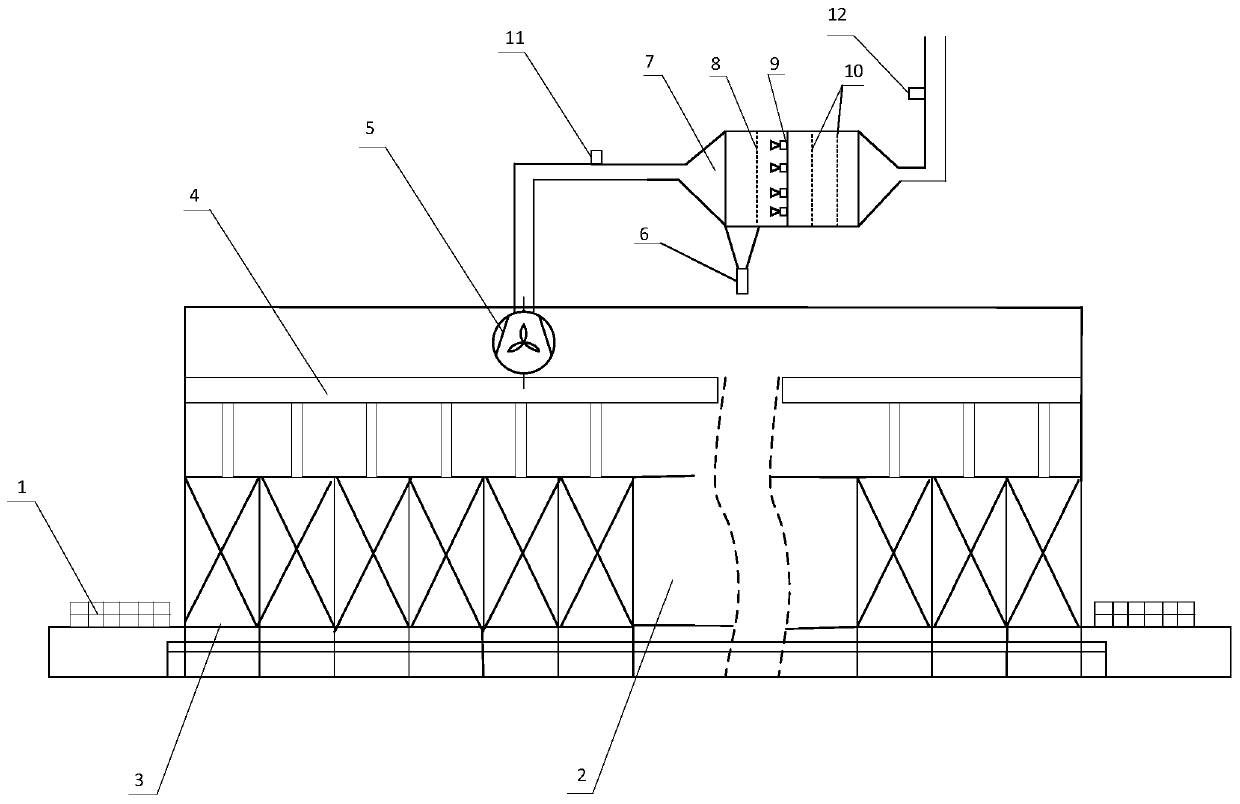

[0032] Such as figure 1 As shown, the escape ammonia treatment device of a tunnel kiln for calcining denitrification catalysts in the present invention includes a waste gas collection pipe 4, an exhaust fan 5, and a waste gas reactor 7; The fan 5 transports the exhaust gas to the exhaust gas reactor 7, removes the escaped ammonia and dust particles in the exhaust gas, and then empties or reuses it; the exhaust gas reactor 7 contains a dust removal filter cloth layer 8, a back-blowing device 9, Ammonia removal filter cloth layer 10, the dust removal filter cloth layer 8 is used to remove dust and salt particles in the exhaust gas, and the back blowing device 9 regularly purges the dust removal filter cloth layer to reduce its gas resistance. The grade ammonia removal filter cloth layer 10 is used to catalyze the elimination of ammonia in exhaust gas.

[0033] Wherein, the material of the filter cloth in the dust removal filter cloth layer 8 can be P84, PTFE, or PPS.

[0034] ...

Embodiment 2

[0037] A method for treating slip ammonia in a tunnel kiln for calcining a denitrification catalyst, comprising the following steps,

[0038] Step 1, the exhaust fan 5 forms a negative pressure inside the tunnel kiln through the exhaust gas collection pipe 4, collects the exhaust gas discharged from the tunnel kiln, and transports the collected exhaust gas to the exhaust gas reactor 7;

[0039] Step 2, enter the waste gas in the waste gas reactor 7,

[0040] First, dust, dust and salt particles in the exhaust gas are removed through the dust filter cloth layer 8;

[0041] Secondly, the ammonia in the exhaust gas is catalyzed and eliminated through the multi-stage ammonia removal filter cloth layer 10;

[0042] Finally, the waste gas from which dust particles and ammonia have been removed is discharged out of the waste gas reactor 7 to be emptied or reused.

[0043] Wherein, the discharge fan 5 is a variable frequency fan, and the power is adjusted through a frequency convert...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com