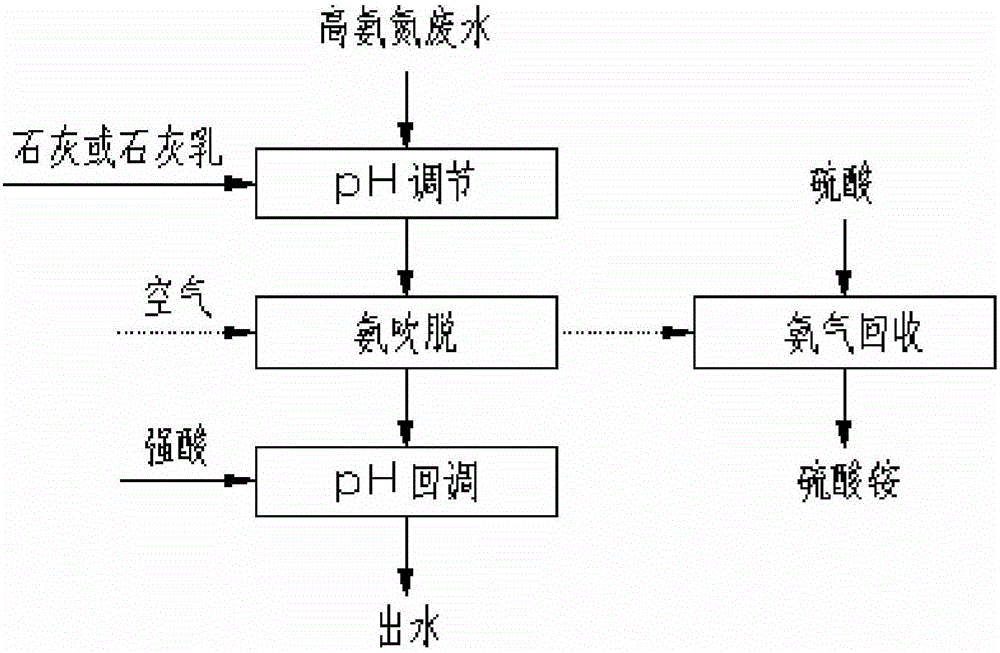

Ammonia stripping process and device for high-ammonia-nitrogen wastewater

A technology of ammonia stripping and high ammonia nitrogen, applied in the direction of ammonia compounds, water pollutants, degassed water/sewage treatment, etc., can solve the problems of stripping tower fouling, secondary pollution, low ammonia removal efficiency, etc., and achieve saving Low consumption, low operating cost, and high ammonia removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

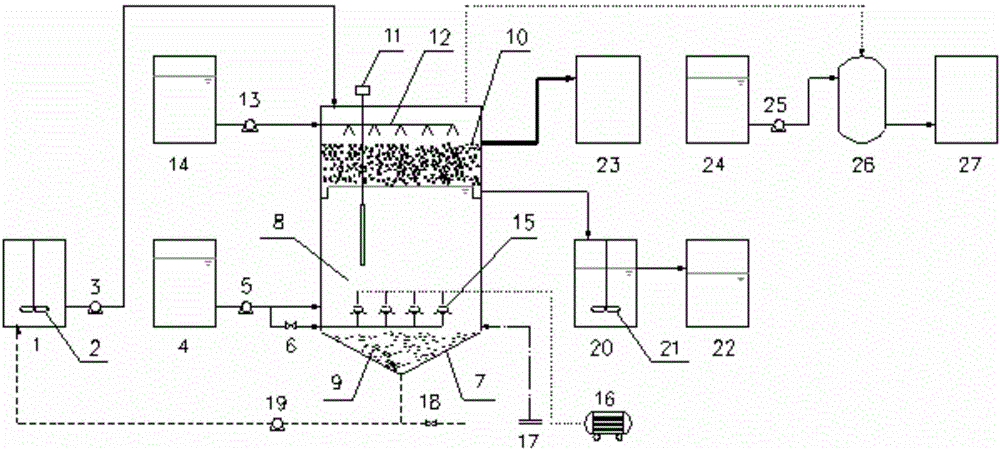

[0028] as attached figure 2 Shown, a kind of device of the ammonia stripping process of high ammonia nitrogen waste water, it comprises raw water box 4, ammonia stripping reactor 7, lime or lime milk box 1, clear water box 14, pH callback box 19, produced water box 22, gas Absorber 26, ammonium sulfate recovery box 27;

[0029] The raw water tank 4 is connected to the ammonia stripping reactor 7, and the first water inlet pump 5 is installed on the connecting pipeline; the lime or lime milk tank 1 is connected to the ammonia stripping reactor 7, and the first dosing pump 3 is installed on the connecting pipeline; The clean water tank 14 is connected with the ammonia blow-off reactor 7, and the second water inlet pump 13 is installed on the connecting pipeline; the outlet water output end of the ammonia blow-off reactor 7 is connected with the pH value callback box 20, and the pH value callback box 20 is connected with the produced water tank 22 Connect; the foam output end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com