Ammonia stripping process and ammonia stripping device for high-concentration ammonia-nitrogen wastewater

An ammonia nitrogen wastewater, high concentration technology, applied in water pollutants, heating water/sewage treatment, degassed water/sewage treatment, etc., can solve the problems of high energy consumption, easy scaling and blocking of packing, and low ammonia stripping efficiency. , to achieve the effects of low energy consumption, good gas-water mixing effect, and avoidance of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

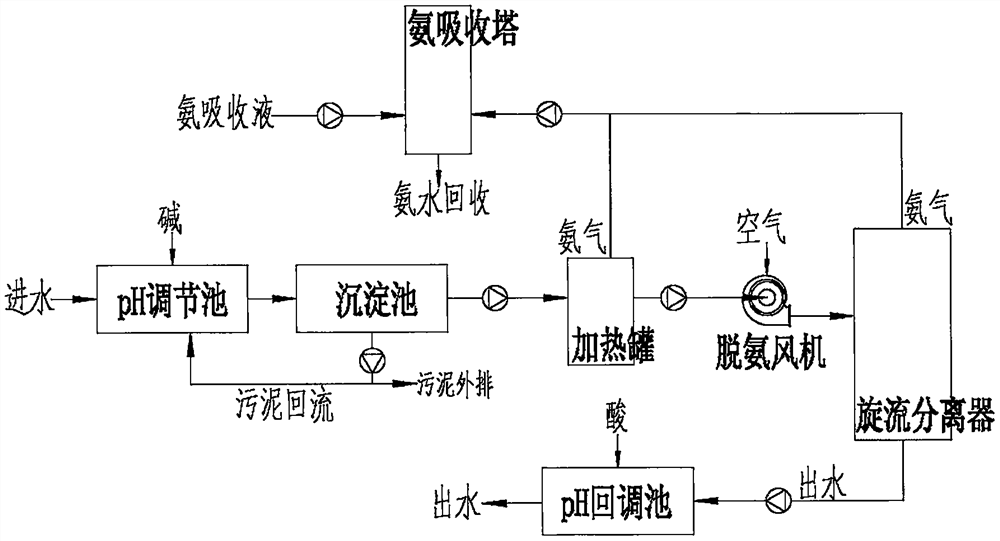

[0024] as attached figure 1 Shown, a kind of ammonia stripping process of high-concentration ammonia-nitrogen wastewater is characterized in that it comprises the following steps: (1) high-ammonia-nitrogen wastewater enters a pH adjustment tank, and simultaneously adds alkali to adjust the pH value of wastewater to the pH adjustment tank. (2) The effluent from the pH adjustment tank enters the sedimentation tank for mud-water separation to obtain supernatant and sedimentation sludge. (3) The supernatant of the sedimentation tank enters the heating tank to heat up, the sludge in the sedimentation tank is partially returned to the pH adjustment tank, and the remaining part is discharged. (4) The water out of the heating tank enters the deamination fan, and at the same time, air also enters the deamination fan, which is vigorously stirred and mixed in the deamination fan to form a gas-water mixture, and then enters the cyclone separator to separate into gas and water. The exhaus...

Embodiment 2

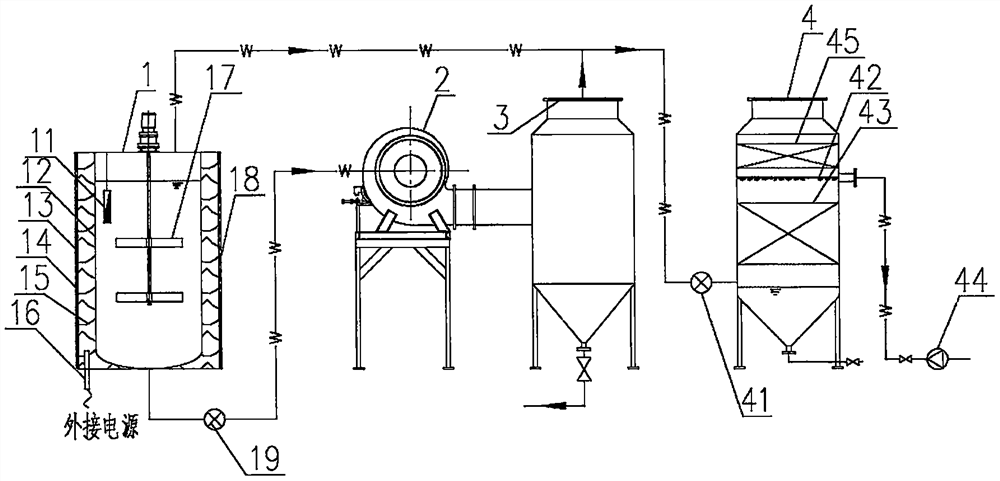

[0027] An ammonia stripping device for high-concentration ammonia-nitrogen wastewater, which includes a heating tank 1, a deammonization fan 2, a cyclone separator 3 and an ammonia absorption tower 4, the heating tank 1 and the deammonization fan 2 are connected by pipelines, and the connecting pipeline is equipped with There is a lifting pump 19, the ammonia removal fan 2 is connected to the cyclone 3 by pipelines, the exhaust end of the heating tank 1 and the exhaust end of the cyclone 3 are connected to the ammonia absorption tower 4 by pipelines, and an induced draft fan is installed on the connecting pipeline 41.

[0028] The heating tank 1 includes an inner tank body 12 and an outer tank body 13, a heating medium heat transfer oil 15 is filled between the inner tank body 12 and the outer tank body 13 and an electric heating tube 16 is provided, the inner tank body 12 is provided with a stirrer 17, and the outer tank body 13 The outside of the tank body 14 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com