Hydraulic jet air cyclone

A technology of hydraulic jet and cyclone, applied in the field of chemical engineering, can solve problems such as unreasonable design, and achieve the effects of enhanced gas-liquid coupling effect, high gas-liquid mass transfer efficiency, and high mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

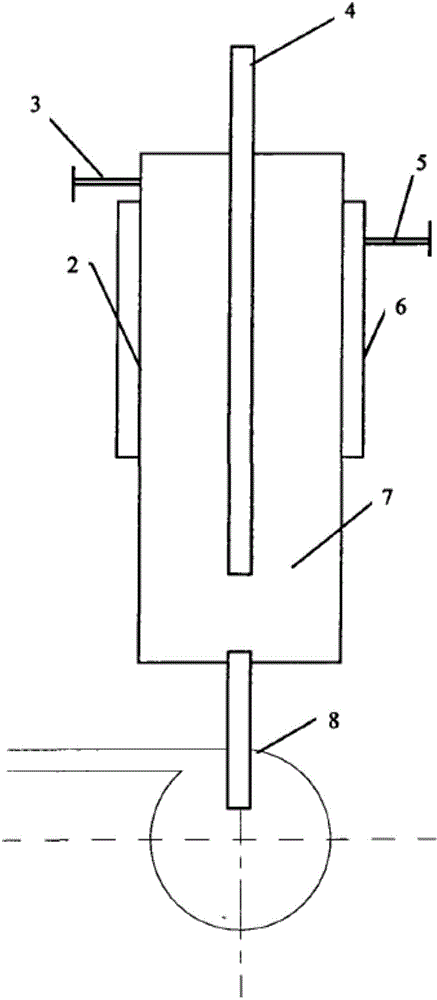

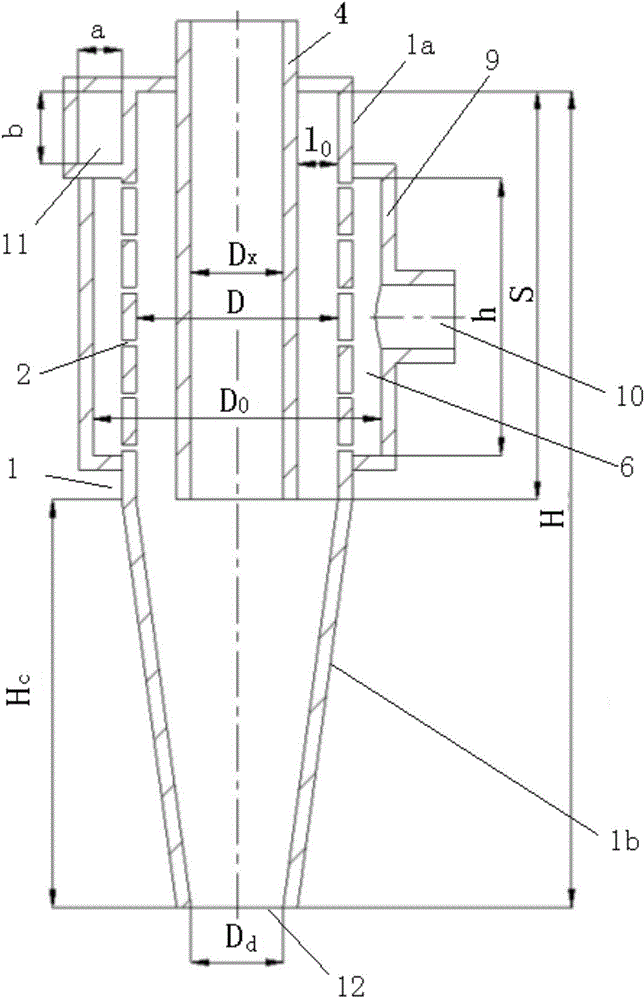

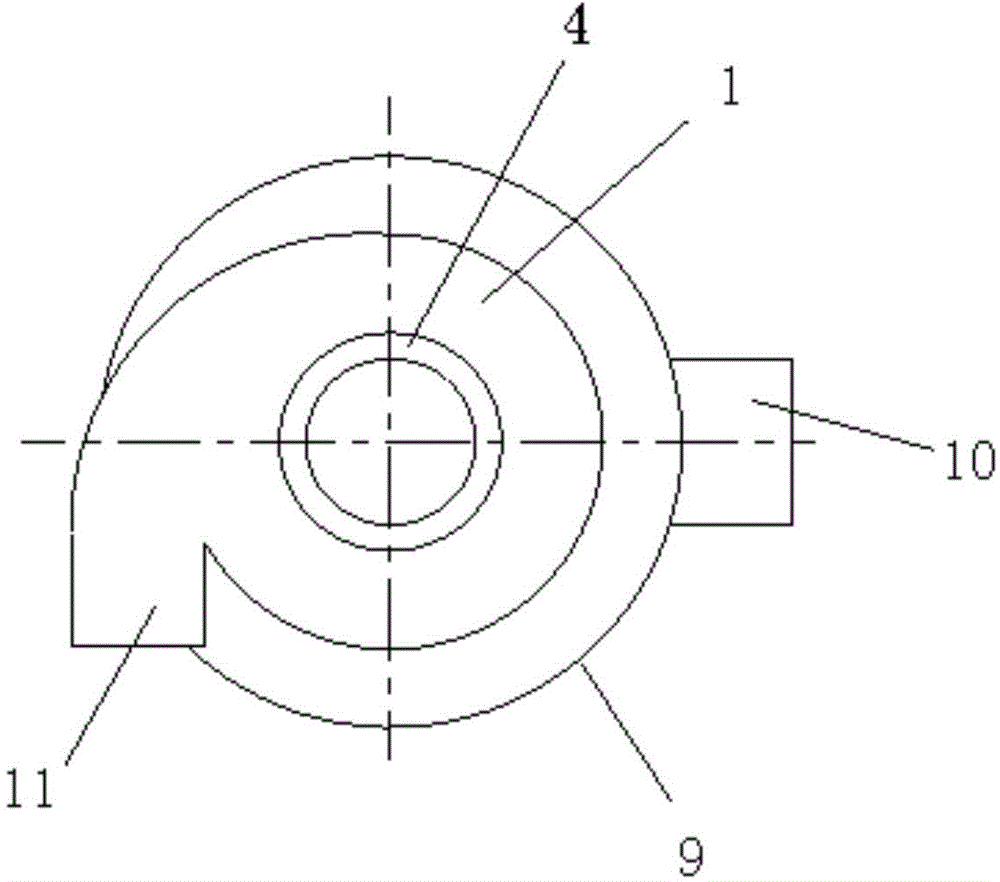

[0031] Such as figure 2 with image 3 The hydrojet air cyclone shown includes an air cyclone and a hydrojet atomization chamber 6. The air cyclone is composed of a central exhaust pipe 4 and a cyclone cylinder 1 set. The upper end of the central exhaust pipe 4 Extending out of the cyclone cylinder 1, the lower end is lower than the lower end of the hydro-jet atomization chamber 6. The cyclone cylinder 1 is provided with a swirl port 11, and the swirl port 11 is connected to the cyclone cylinder 1. Compressed gas is input inside, and the compressed gas rotates at high speed in the cyclone cylinder 1 to form a gas swirl field. There is a cylindrical outer jacket 9 on the periphery of the upper part of the cyclone cylinder 1, which is connected with the cyclone cylinder 1 The outer wall of the hydro-jet atomization chamber 6 is connected to form a hydro-jet atomization chamber 6, and a plurality of spray holes 2 are opened from top to bottom on the outer wall of the part of the...

Embodiment 2

[0050] Such as Figure 12 For the hydrojet air cyclone shown, the cyclone body 1 can also be a cylindrical body. All the other are the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com