A kind of treatment method of ammonia nitrogen wastewater

A technology of ammonia nitrogen wastewater and treatment method, which is applied in water/sewage treatment, degassed water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of insufficient countercurrent contact between ammonia nitrogen wastewater and steam and low deamination efficiency , the difficulty of free ammonia, etc., to achieve the effect of enhancing volatilization, saving water, and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

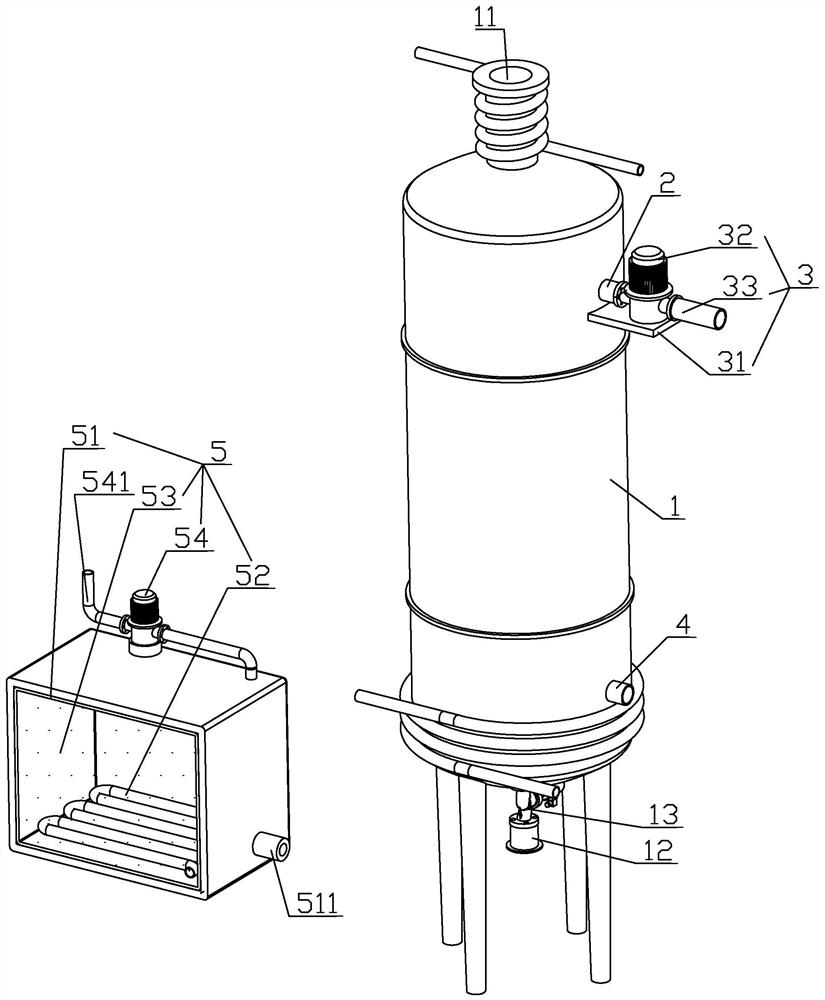

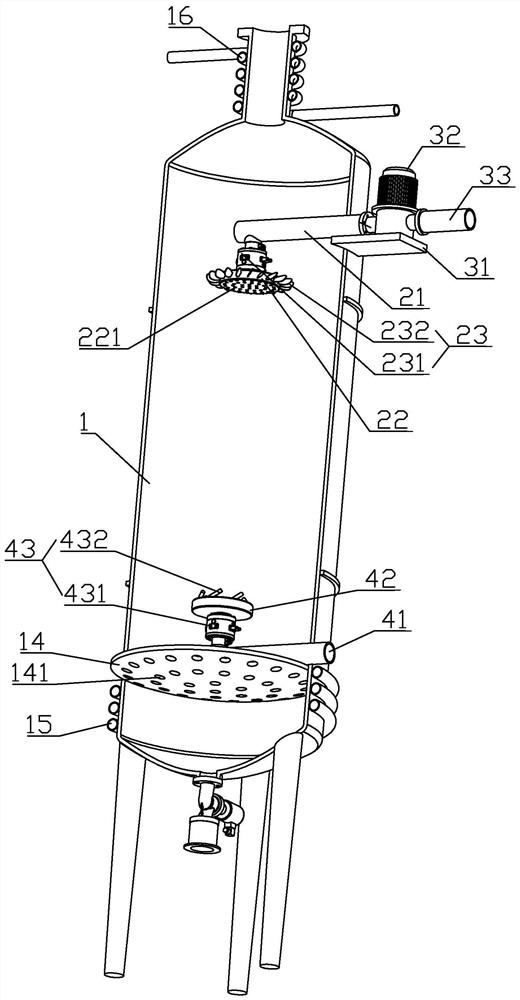

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0037] refer to figure 1 , is a kind of treatment method of ammonia nitrogen wastewater disclosed by the present invention, comprises the following steps:

[0038] A1. Pretreatment of high-concentration ammonia nitrogen wastewater;

[0039] A2. The pretreated ammonia nitrogen wastewater is first subjected to heat exchange treatment, and then subjected to concentration and temperature increase treatment;

[0040] A3. Use a stripper to strip the heated ammonia nitrogen wastewater to obtain ammonia-containing steam and deammonia wastewater;

[0041] A4. Connect the ammonia-containing steam in step A3 to step A2 and carry out thickening treatment to ammonia nitrogen wastewater;

[0042] A5. Heat the deammonization wastewater in step A3 to generate secondary steam and high-temperature deammonization wastewater, and connect the secondary steam to the stripping t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com