Device and method for dissolved gas film deamination

A gas-dissolved and deammonia technology, applied in chemical instruments and methods, degassed water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of high treatment cost, secondary pollution, low pH value, etc. To achieve the effect of convenient operation and management, easy modular design, and improved deamination efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

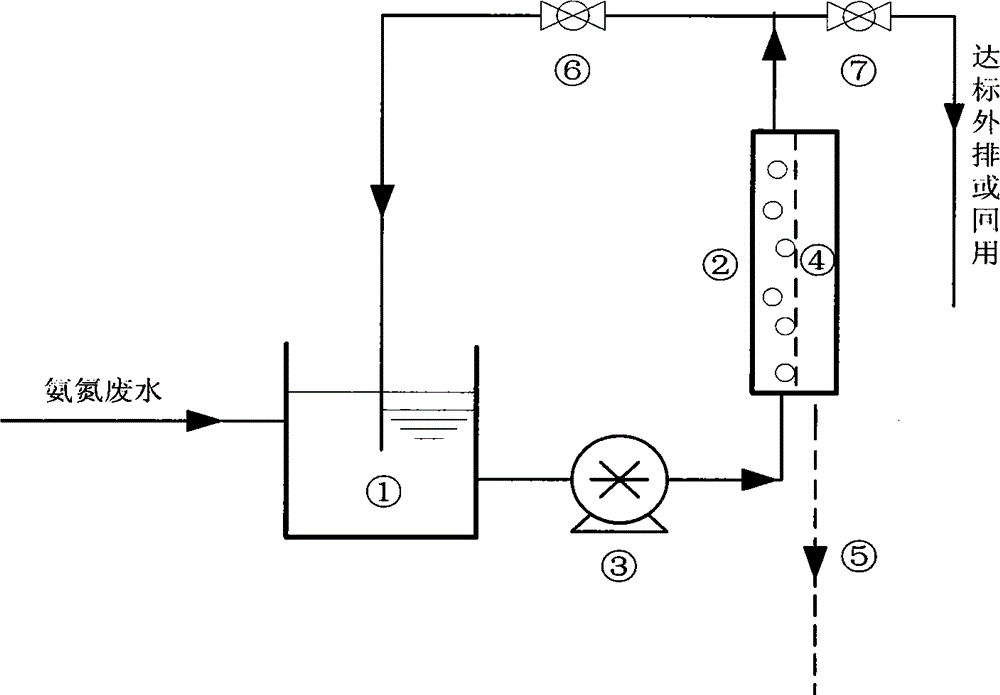

[0032] Such as figure 1 As shown, the arrow indicates the direction of water flow, and the water flow must flow in the direction of the arrow, not against the direction of the arrow.

[0033] The equipment of the present invention for dissolved gas membrane deamination comprises a membrane deamination circulation tank, a dissolved air pump, a dissolved gas membrane deamination membrane module, an ammonia recovery system and a fluid flow switching valve, the membrane deamination circulation tank and the dissolved gas The deamination membrane module forms a circulation loop through the dissolved air pump, the dissolved air pump is connected to the membrane deamination circulation tank, the described gas-dissolved deamination membrane module is connected to the ammonia recovery system, and the The fluid flow direction switching valve 1 and the fluid flow direction switching valve 2 are used to adjust and control the flow direction and flow rate of the waste water liquid.

[0034...

Embodiment 1

[0037] Containing NH 4 The concentration of ammonia nitrogen in the Cl wastewater is 1200mg / L, and the pH value of the solution is 8.6. First, use 0.1M NaOH solution to adjust the pH value to always be 10.0. The liquid flow rate of the film deamination circulation system is 0.1m / s, and the vacuum degree of the vacuum pump is set at 90kPa. Here, the dissolved gas membrane deamination membrane module is a polypropylene hollow fiber membrane module made in the laboratory, with a porosity of 40%, the inner and outer diameters of the membrane filaments are 0.22mm / 0.30mm, the membrane pore diameter is 0.02-0.08μm, and the effective length of the membrane filaments is 10mm, the effective membrane area of the membrane module is 0.18m 2 . Use the dissolved air pump to pre-dissolve the air to form dissolved air water containing 3% air before the waste water contacts the surface of the membrane filament. Adjust the readings of the instruments of the dissolved air pump as follows: pre...

Embodiment 2

[0039] The concentration of ammonia nitrogen in a certain wastewater is about 3200mg / L, the water temperature is 52°C, and the pH is 6.7. The deamination process is carried out by the dissolved air membrane deamination method.

[0040] First, use 40% NaOH solution to adjust the pH of the wastewater to 11.0, control the water temperature to 50°C, and introduce 40L of wastewater to the membrane deamination circulation tank. After filtering through a 10μm filter, control the amount of dissolved air in the dissolved air pump to 5% to form dissolved air water, which is then pumped into the dissolved air membrane deamination module. The membrane module adopts polypropylene degassing membrane module, which has a large specific surface area. The inner / outer diameter of the membrane filament is 0.3mm / 0.22mm, the pore diameter is 0.04-0.06μm, the porosity is 40%, and the membrane surface area is 0.9m2. The vacuum degree is set to -95kPa, the liquid flow rate is 0.1m / s, and the readings...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com