Membrane absorption deamination method and system based on direct contact microporous aeration enhancement

A microporous aeration and contact technology, applied in the field of membrane absorption deamination system, can solve problems such as high volatilization rate, maintain long-term efficient operation, and have the advantage of operating cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

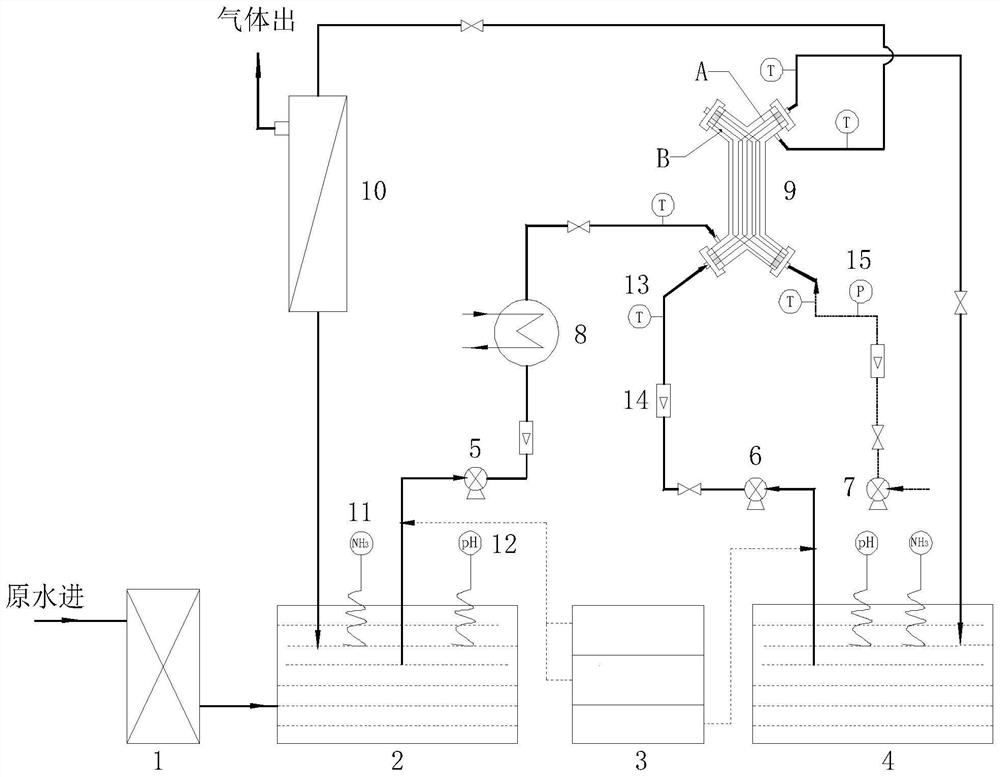

[0055] 30L of hydrometallurgical wastewater with an ammonia nitrogen concentration of 3000mg / L was treated by the membrane absorption deamination method enhanced by direct contact microporous aeration.

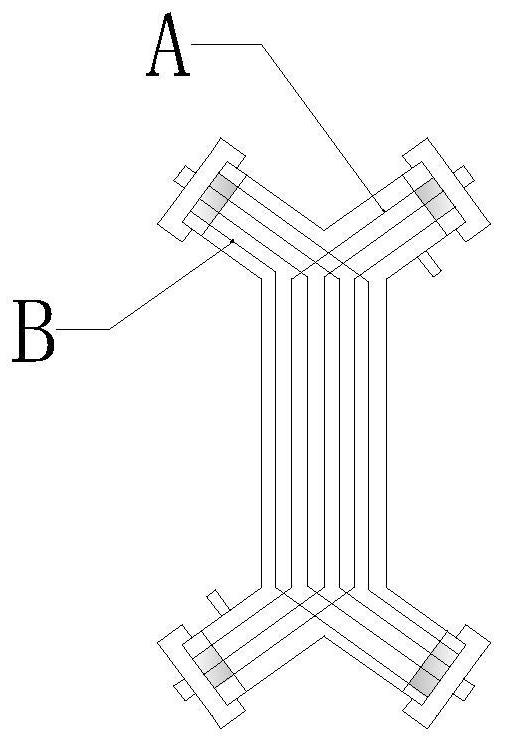

[0056] Membrane absorption deamination process: flocculation and sedimentation of the ammonia nitrogen wastewater stock solution through the pretreatment device, and filtering to remove most of the suspended solids. The pretreated high ammonia nitrogen wastewater enters the raw water circulation tank, and sodium hydroxide is added to the raw water circulation through the dosing system to adjust the pH value of the raw water to 11.5, the feed liquid pump is turned on, and the ammonia nitrogen wastewater from the raw water circulation tank enters the heat exchanger for preheating After reaching 35°C, pump into the shell side of the hollow fiber membrane contactor assembly of polytetrafluoroethylene (PTFE, filtration pore size: 0.2-0.45μm); add 20L of sulfuric acid with a concentr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com